220kV transformer station secondary equipment prefabricated cabin

A secondary equipment, 220kv technology, applied in the direction of distribution substation, substation/distribution device casing, substation/switchgear cooling/ventilation, etc., can solve the problem of not optimizing the layout of cables/optical cables, realizing different functions, and occupying an area Large and other problems, to achieve the effect of flexible layout, good leakage resistance, and reduced floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

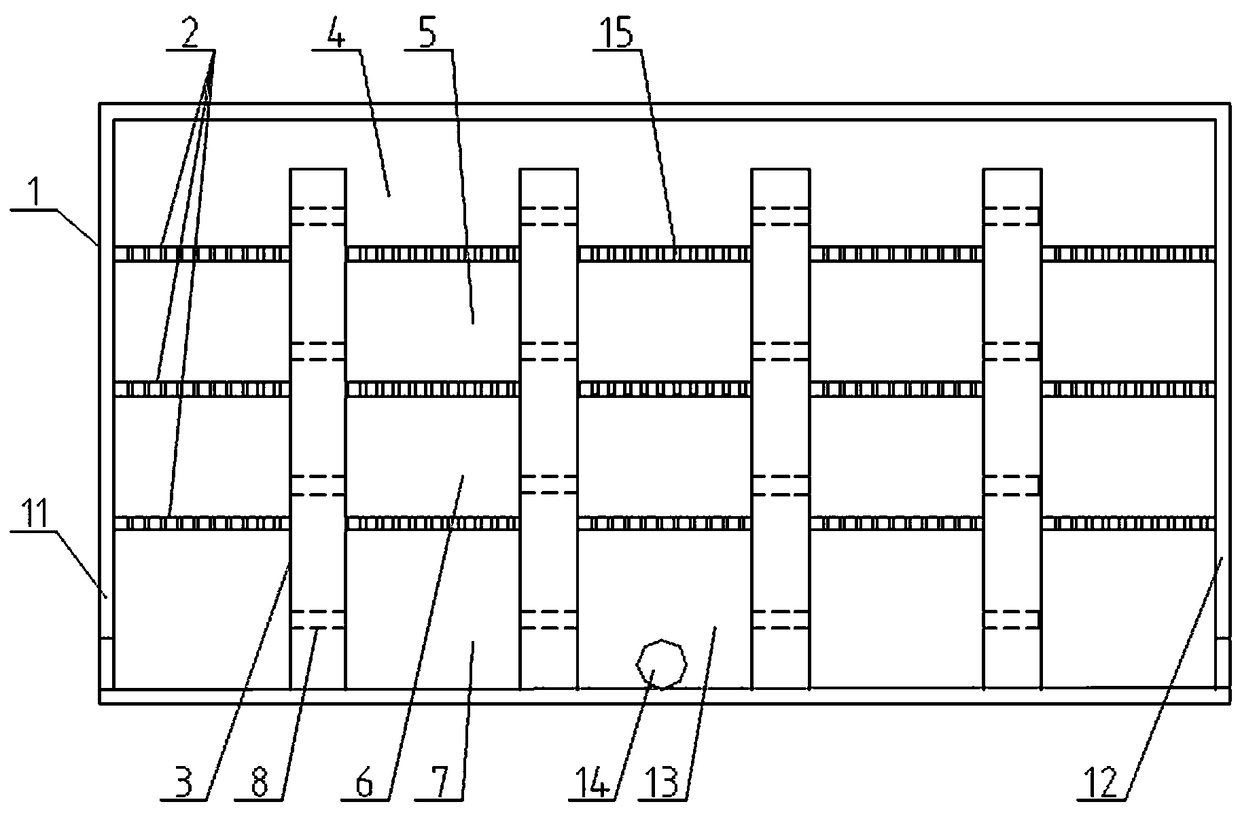

[0043] like figure 1 As shown, the prefabricated cabin of the secondary equipment of the 220kV substation includes a prefabricated cabin shell 1 in the shape of a cuboid, and the prefabricated cabin shell 1 is provided with three transverse load-bearing plates 2 and a plurality of horizontal load-bearing plates 2 that cooperate with the three The vertical support plate 3 and the three transverse bearing plates 2 divide the inner cavity of the prefabricated cabin shell 1 from top to bottom into 220kV secondary equipment area 4, main transformer secondary equipment area 5, and 110kV secondary equipment Area 6 and cable storage area 7, each of the vertical support plates 3 has four first cable holes 8 through left and right, and the four first cable holes 8 are respectively located in the 220kV secondary equipment Area 4, main transformer secondary equipment area 5, 110kV secondary equipment area 6 and cable storage area 7; the number of vertical support plates 3 is four.

[004...

Embodiment 2

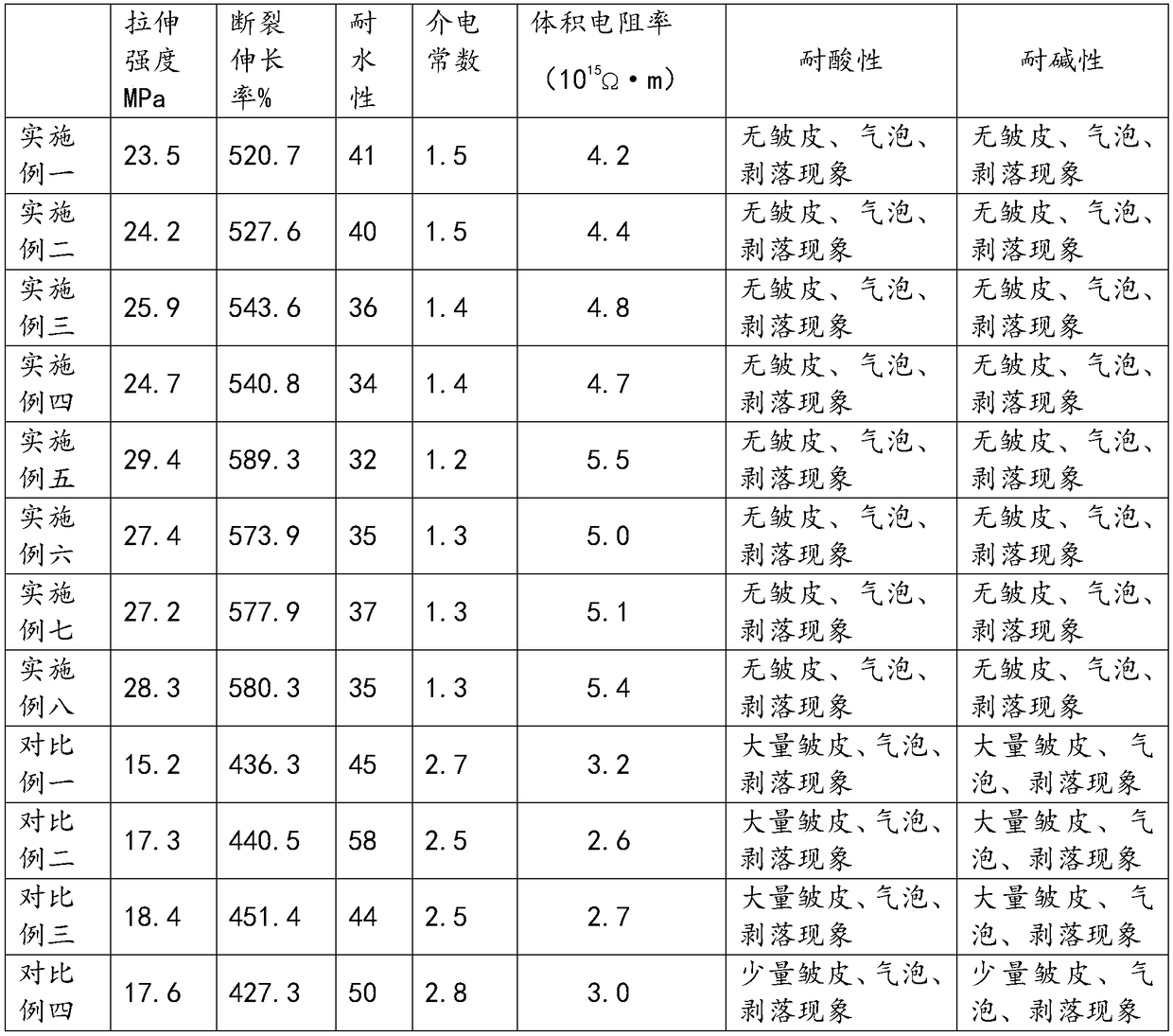

[0058] The difference from Example 1 is that the components and contents contained in the insulating and corrosion-resistant layer are: 21 parts by weight of epoxy resin, 13 parts by weight of polytetrafluoroethylene, 3-glycidyl ether oxypropyl trimethoxy 4 parts by weight of silane, 13 parts by weight of nano oxide, 4.6 parts by weight of polydienyl propylene dimethyl ammonium chloride, 18 parts by weight of polyvinylidene fluoride, 36 parts by weight of N,N-dimethylacetamide, 6.8 parts by weight of sodium silicate, 9 parts by weight of hexamethylenetetramine, 3.5 parts by weight of styrene, 3.4 parts by weight of flame retardant DOPO, 21 parts by weight of acetone, and 41 parts by weight of water.

[0059] The nano-oxide is a mixture of nano-magnesia, nano-silicon dioxide, and nano-titanium dioxide, and the weight ratio of nano-magnesia: nano-silicon dioxide: nano-titanium dioxide is 4:3:3.

[0060] The preparation method of the insulating corrosion-resistant layer comprises...

Embodiment 3

[0067] The difference from Example 1 is that the components and contents contained in the insulating and corrosion-resistant layer are: 23 parts by weight of epoxy resin, 14 parts by weight of polytetrafluoroethylene, 4.2 parts by weight of 3-aminopropyltriethoxysilane Parts by weight, 14 parts by weight of nano oxide, 4.8 parts by weight of polydienyl propylene dimethyl ammonium chloride, 19 parts by weight of polyvinylidene fluoride, 37 parts by weight of N,N-dimethylacetamide, methyl silicic acid 6.9 parts by weight of sodium, 9.2 parts by weight of hexamethylenetetramine, 3.7 parts by weight of hydroquinone, 3.6 parts by weight of tricresyl phosphate, 22 parts by weight of acetone, and 43 parts by weight of water.

[0068] The nano-oxide is a mixture of nano-magnesia, nano-silicon dioxide, and nano-titanium dioxide, and the weight ratio of nano-magnesia: nano-silicon dioxide: nano-titanium dioxide is 4:3:3.

[0069] The preparation method of the insulating corrosion-resist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com