Suspension type cooling tower packing hanging bracket

A cooling tower and suspension technology, which is applied in the field of suspension cooling tower filler hangers, can solve the problems of large ventilation resistance, unfavorable cooling efficiency, and high civil construction investment, so as to reduce ventilation resistance, improve cooling efficiency, and expand air quality. The effect of circulation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

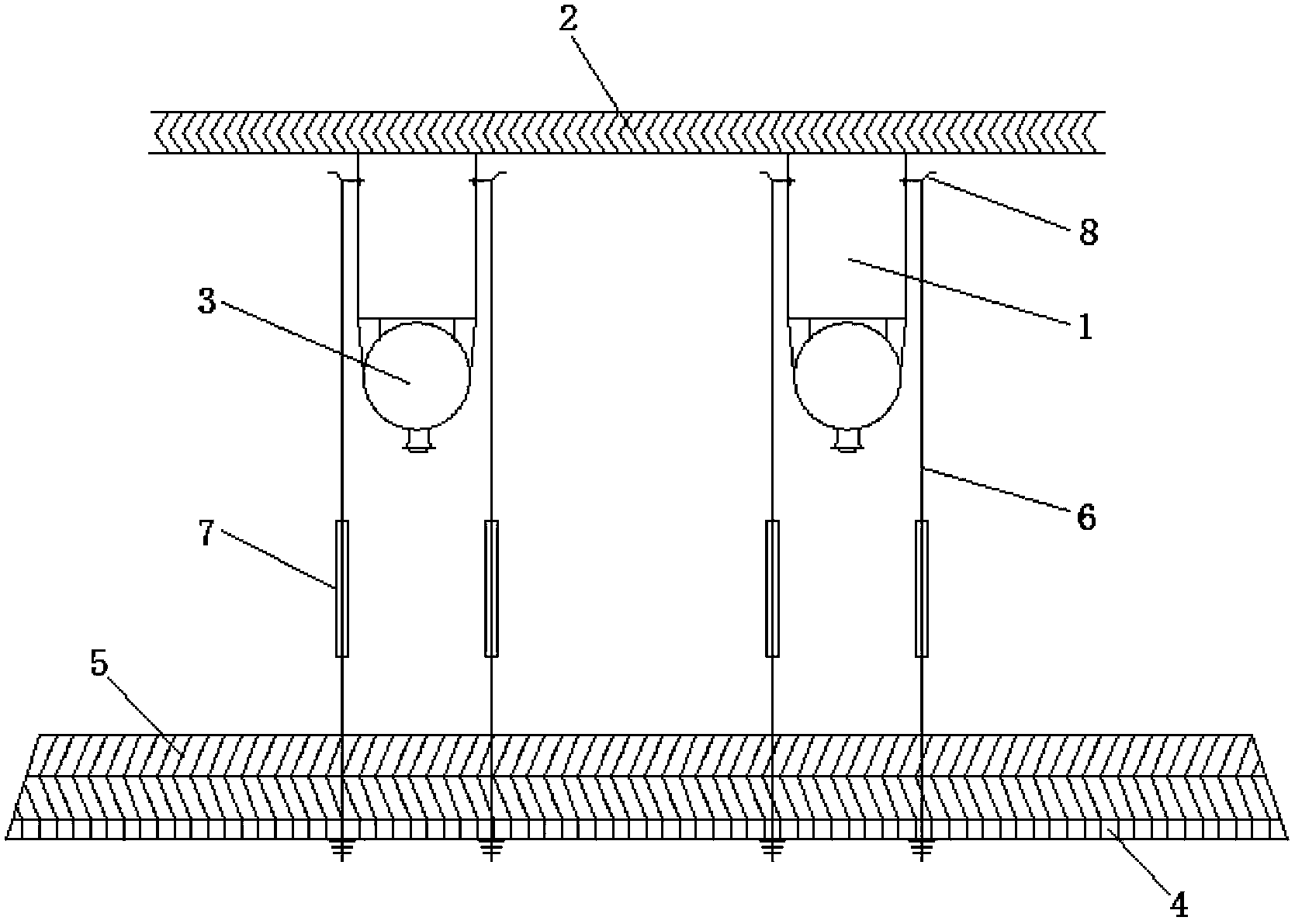

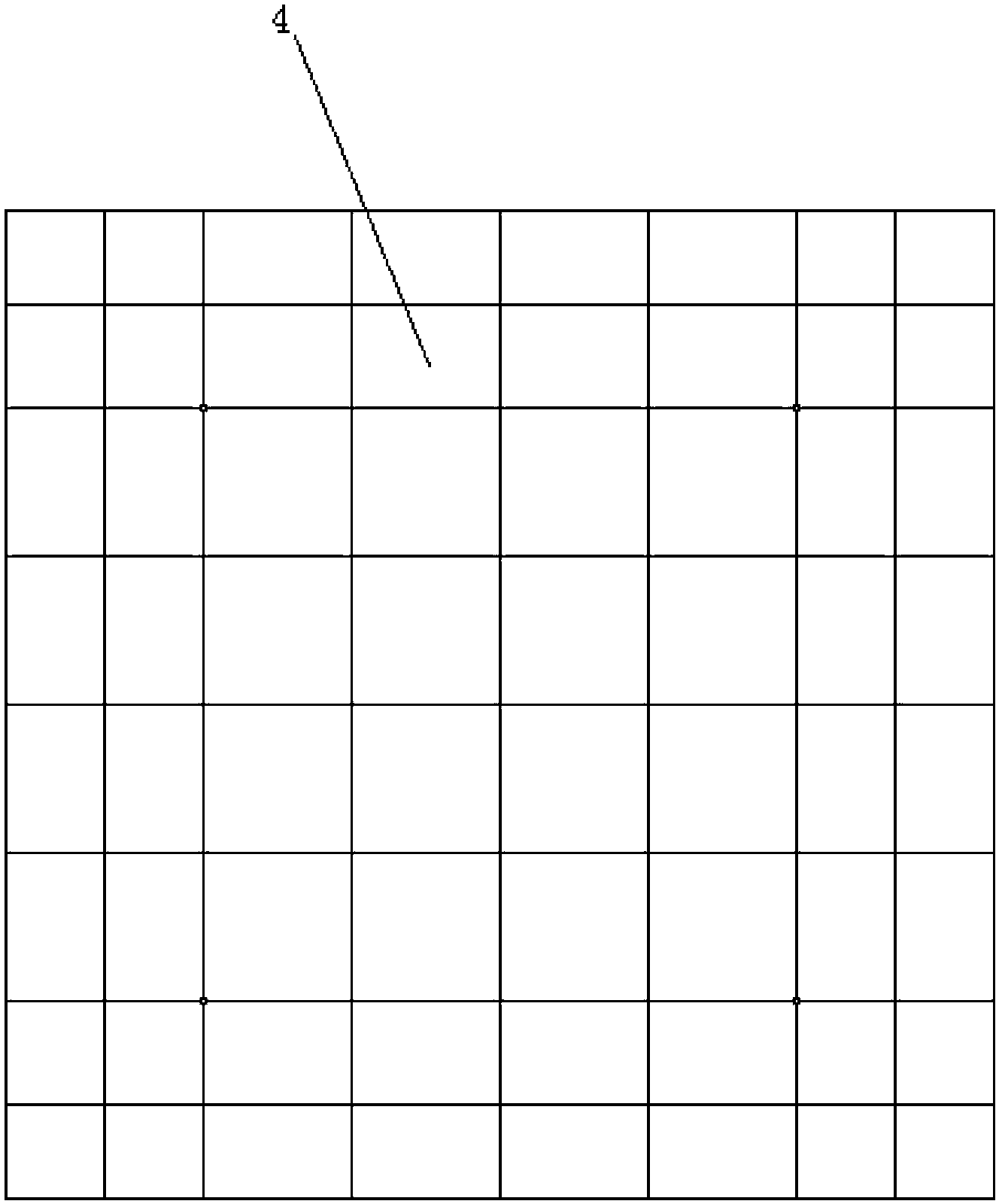

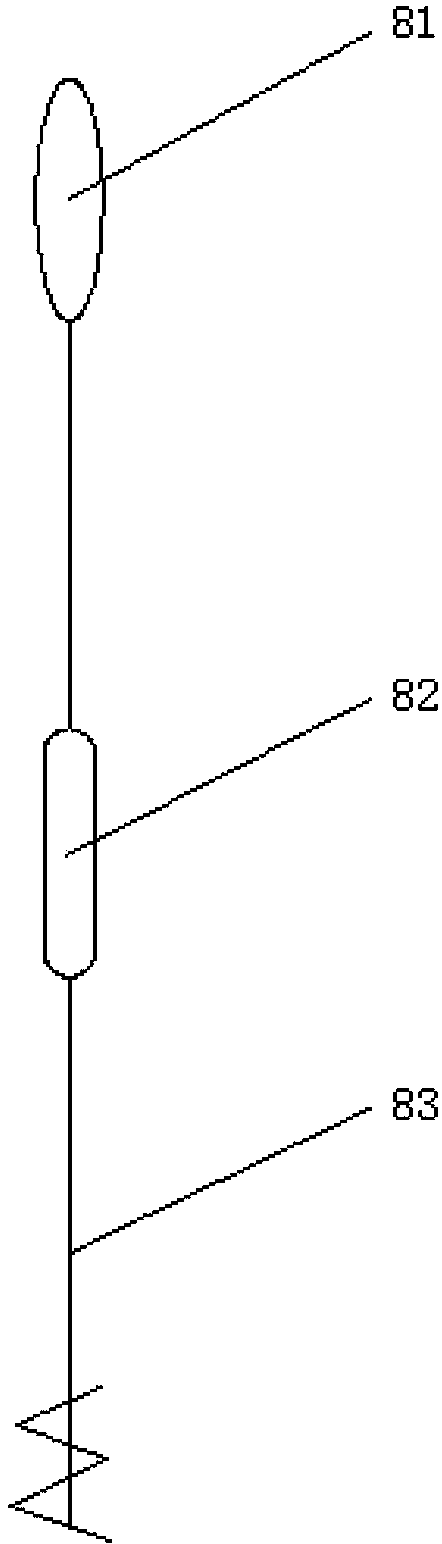

[0012] See Figure 1 to Figure 3 , the present invention has a load-bearing beam 1, the top of the load-bearing beam 1 is provided with a water eliminator 2, and the lower end of the load-bearing beam 1 is provided with a sprinkler 3; Filling 5 is placed; the support plate 4 is hoisted on the load-bearing beam 1 through the suspender 6; the side of the load-bearing beam 1 is provided with a hook 8; the hook 8 includes an embedded part 81 buried in the load-bearing beam 1, The stopper 82 and the hook body 83 arranged on the outside of the load-bearing beam 1, the hook body 83 is provided with threads; the support plate 4 is made of a square tube and flat iron and four corners are provided with mounting holes; one end of the suspender 6 It is hung on the hook body 83 and fixed by a nut, and the other end is provided with a screw thread and passed through the mounting hole on the support plate 4 to be fixed with the support plate 4 through the nut; the middle part of the boom 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com