Operation control method and system for multiple cooling fans

A technology for cooling fans and operation control, applied in engine control, pump control, mechanical equipment, etc., can solve the problems of not using electricity to save energy, large energy consumption, increase the operating burden and monitoring intensity of central control operators, and reduce monitoring and control. Strength, the effect of reducing the operating burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] The operation control method and operation control system provided by the present invention will be described in detail below with the operation control of 9 fans at the work site.

[0023] Divide the 9 fans on site into three groups;

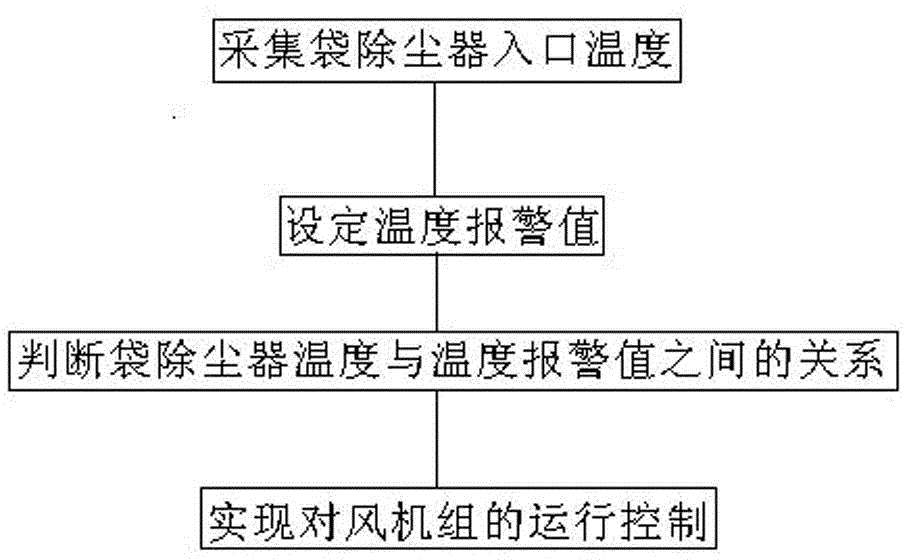

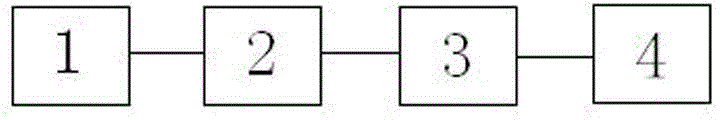

[0024] Sampling the inlet temperature of the bag filter through the temperature sensor 1;

[0025] The inlet temperature of the bag filter is displayed in real time through the alarm digital display 2, and three-way temperature alarm values matching the three groups of fans are set in the alarm digital display 2, and the three-way temperature alarm values are adjusted from low temperature to high temperature According to the actual situation of the fan operation site, set the first temperature alarm value to 100°C, the second temperature alarm value to 130°C, and the third temperature alarm value to 160°C;

[0026] The above-mentioned three-way temperature alarm value and the inlet temperature of the bag filter are transmitted to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com