Low-ash-fusion coal fired boiler adopting horizontal extended furnace

A pre-furnace, ash melting point technology, applied in the combustion of lump fuel and liquid fuel, combustion of lump fuel and gaseous fuel, combustion of lump fuel and powder fuel, etc., can solve furnace slagging and other problems to achieve the effect of solving slagging, convenient operation and ensuring normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

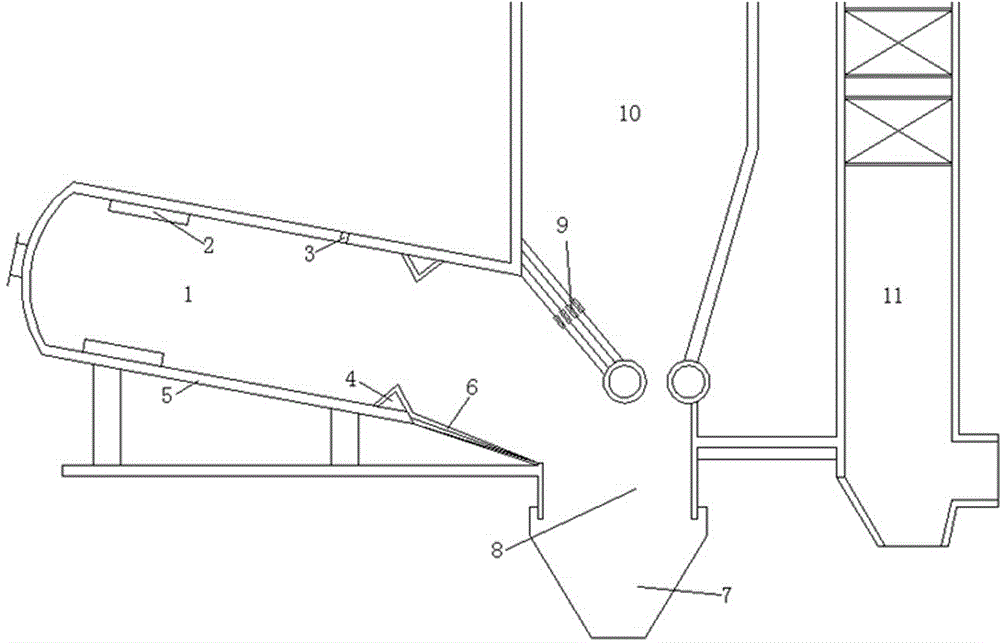

[0022] Such as figure 1 A boiler with low ash melting point coal is shown, which adopts a horizontal front furnace, including a horizontal front furnace 1 fixed at the front of the furnace body, and the furnace wall 5 of the front furnace is surrounded by a water-cooled wall. Wherein the inner surface of the water-cooled wall is laid with a refractory paint layer; the furnace outlet 8 of the horizontal front furnace 1 communicates with the cooling chamber 10, wherein the front end of the furnace outlet 8 is provided with an inclined furnace bottom 6, and the junction with the cooling chamber 10 is provided There is a slag tube bundle 9, and a slag pool 7 is arranged at the lower part; a burner 2, an overburning air nozzle 3, and a flame angle 4 are arranged on the front furnace, and the overburning air nozzle 3 is arranged at a distance from the primary tuyere 4 of the lowest layer At a distance of ~5 meters, the folding flame angle 4 is arranged at the front part of the incl...

Embodiment 2

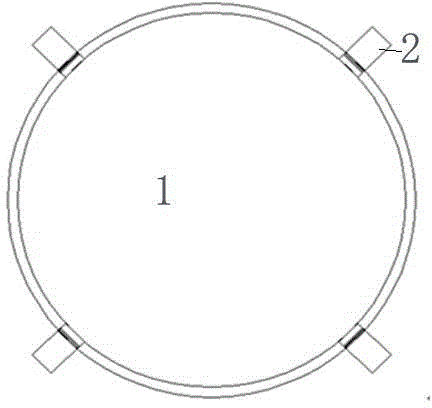

[0025] Such as figure 2 Shown is a boiler using low-ash melting point coal with a horizontal front furnace. The front furnace 1 is arranged with four sets of burners 2 tangentially injected into the furnace, and other structures are the same as in Embodiment 1. This structure is suitable for the situation where the boiler capacity is large and the cross-section of the front furnace is large.

Embodiment 3

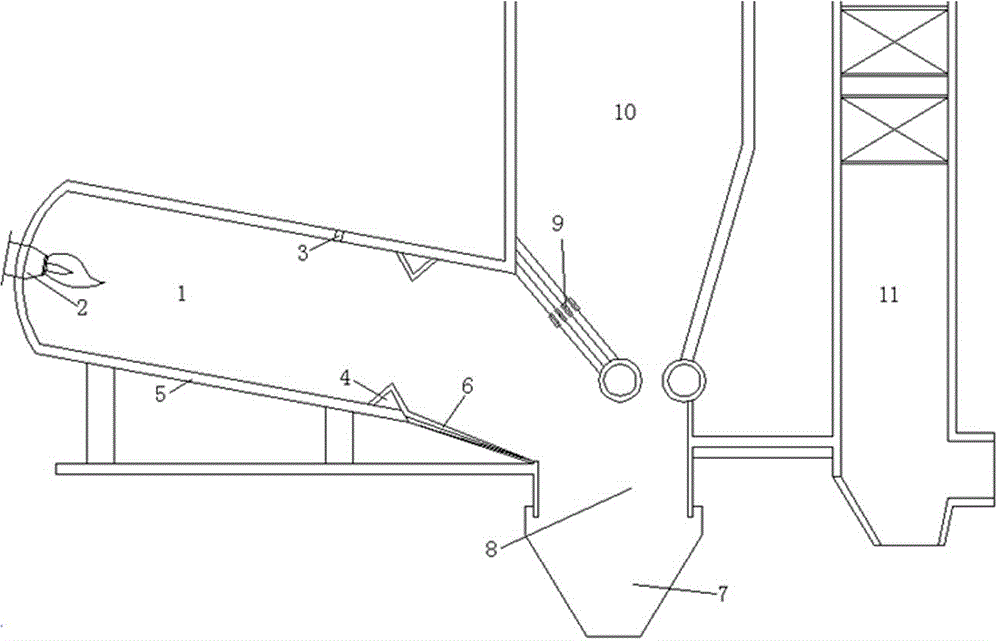

[0027] Such as image 3 A boiler with low ash melting point coal is shown, which adopts a horizontal front furnace, including a horizontal front furnace 1 fixed at the front of the furnace body, and the furnace wall 5 of the front furnace is surrounded by a water-cooled wall. Wherein the inner surface of the water-cooled wall is laid with a refractory paint layer; the furnace outlet 8 of the horizontal front furnace 1 communicates with the cooling chamber 10, wherein the front end of the furnace outlet 8 is provided with an inclined furnace bottom 6, and the junction with the cooling chamber 10 is provided There is a slag tube bundle 9, and a slag pool 7 is arranged at the lower part; a burner 2, an overburning air nozzle 3, and a flame angle 4 are arranged on the front furnace, and the overburning air nozzle 3 is arranged at a distance from the primary tuyere 4 of the lowest layer At a distance of ~5 meters, the folding flame angle 4 is arranged at the front part of the incli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com