Automated Sample Preparation System with Parallel Processing

An automatic sample preparation and parallel processing technology, applied in the preparation of test samples, comprehensive factory control, comprehensive factory control, etc., can solve the problems of manual intervention and fraud, inability to process in parallel at the same time, random and unscientific combination of high-level processing equipment, etc. Achieve the effects of improving precision and representativeness, high degree of automation in sample preparation, and avoiding artificial fraud

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

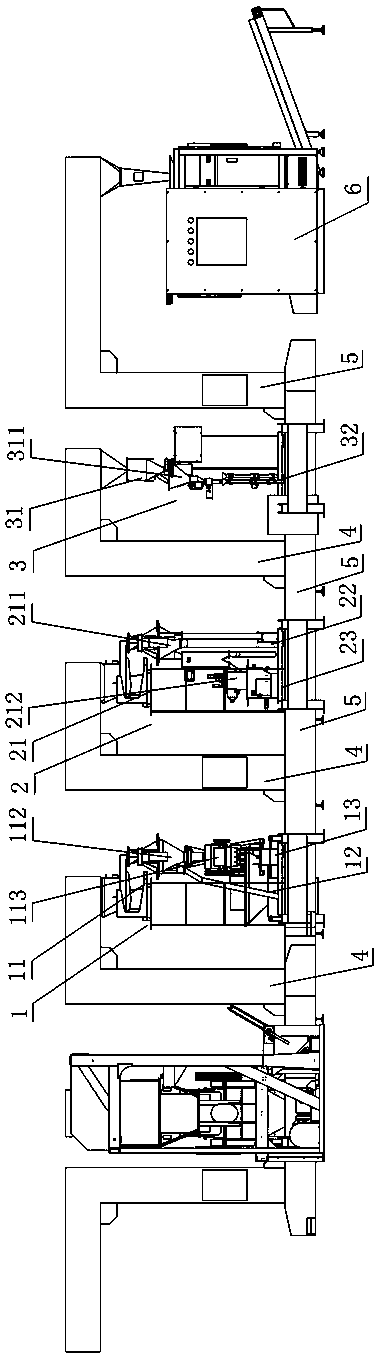

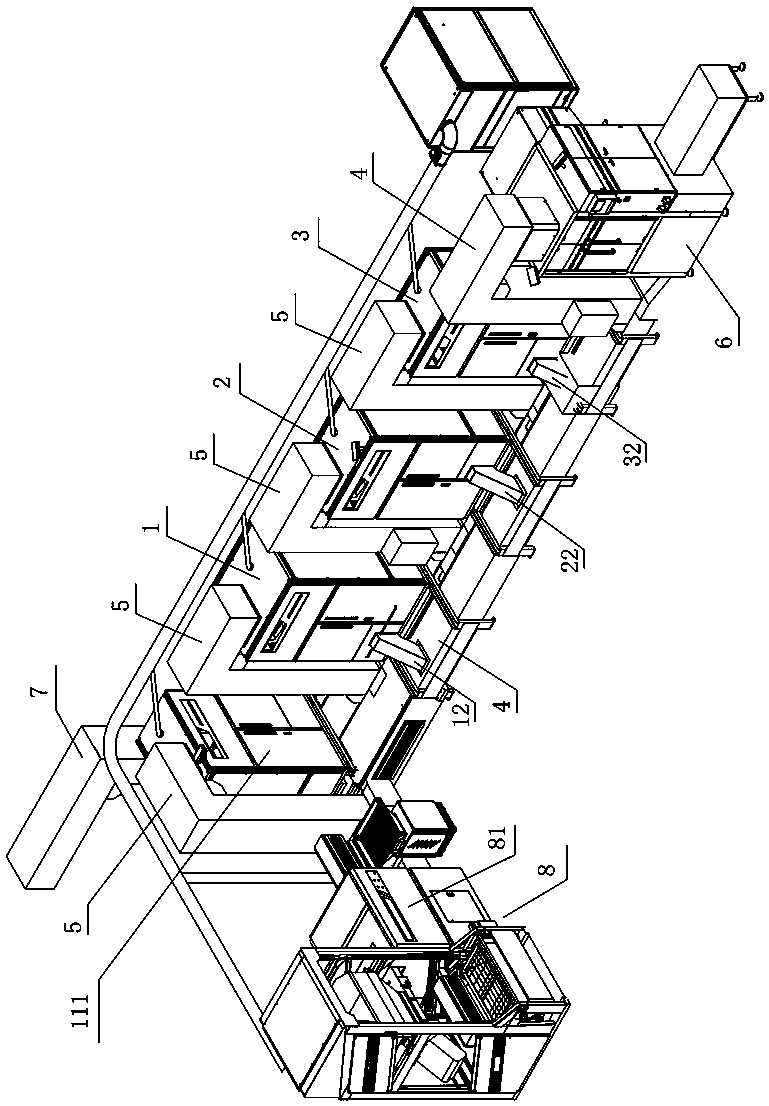

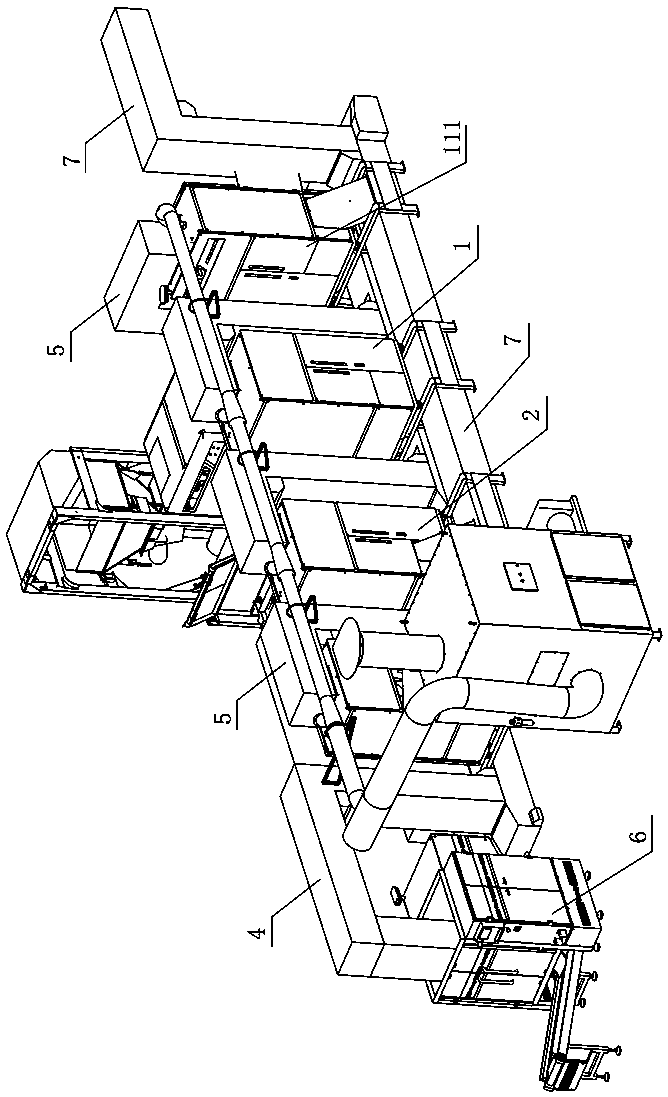

[0032] like figure 1 , figure 2 and image 3 As shown, the present invention provides an automatic sample preparation system with parallel processing function, including a primary processing unit 1, a secondary processing unit 2 and a tertiary processing unit 3 for sample preparation,

[0033] The primary processing unit 1 includes a first sample preparation unit 11, a first output channel 12 and a second output channel 13, the first sample preparation unit 11 is connected with the secondary processing unit 2 through the second output channel 13, when the material After entering the primary processing unit 1, after the first-stage sample preparation treatment of the first sample preparation unit 11, a part of the material is made into a full water sample and output through the first output channel 12 to form the first type of qualified...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com