High-precision gas concentration detection method and detection apparatus thereof

A gas concentration detection and detection device technology, which is applied in the measurement of color/spectral characteristics, etc., can solve the problems of many influencing factors and inaccurate detection results, and achieve the effect of improving detection accuracy and eliminating influence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

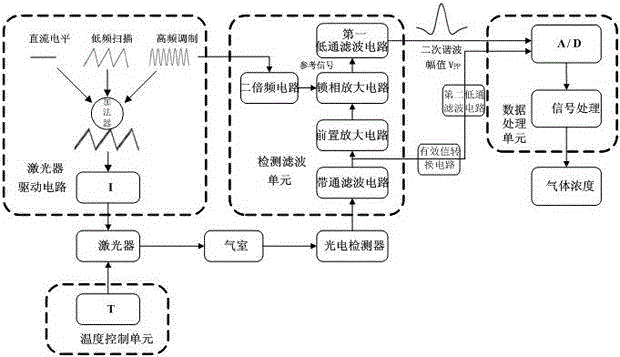

[0031] Embodiment one, see figure 1 As shown, a high-precision gas concentration detection method includes the following steps:

[0032] S1. The op-amp adder adds the low-frequency triangular wave scanning signal, high-frequency sine wave modulation signal and DC signal to the laser drive circuit as the current input of the laser drive circuit;

[0033] S2. The laser driving circuit drives the laser to emit a laser signal, passing through the measured gas in the gas chamber;

[0034] S3. The photoelectric detector receives the laser signal output after being absorbed by the relevant gas in the gas chamber and performs photoelectric detection, converts it into a voltage signal and inputs it to the detection filter unit;

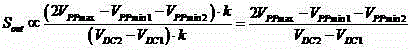

[0035] S4. The detection filter unit performs band-pass filter processing on the converted voltage signal, and one of the output signals is sequentially processed by pre-amplification, phase-locked amplification, and low-pass filter to obtain the second harmo...

Embodiment 2

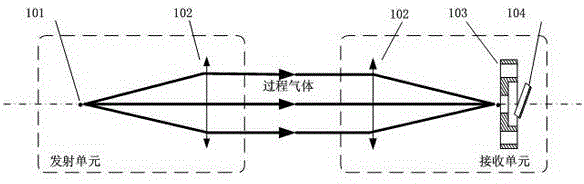

[0047] Embodiment 2, based on a high-precision gas concentration detection method in Embodiment 1, this embodiment provides a high-precision gas concentration detection device, such as figure 1 As shown, it includes a laser emitting device and a photodetector, the laser emitting device includes a laser drive circuit and a laser, the input end of the laser drive circuit is connected to an adder, and the photodetector is connected to a detection filter unit and a data processing unit connected, the detection filter unit includes a current-voltage conversion circuit, a band-pass filter circuit and a preamplifier circuit connected in sequence, one of the output ends of the band-pass filter circuit is sequentially connected with the preamplifier circuit, phase-locked The amplifying circuit is connected to the first low-pass filter circuit, and the other channel is connected to the effective value conversion circuit and the second low-pass filter circuit in sequence, and the output t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com