A Generator Conductive Screw Insulation Wrapping Device

A generator and screw technology, applied in the direction of conductor/cable insulation, etc., can solve the problems of unqualified electrical withstand voltage performance or airtight performance of conductive screw insulation, large fluctuations in insulation quality, and affecting quality indicators, etc., to improve insulation quality , The effect of improving the quality of insulation wrapping and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

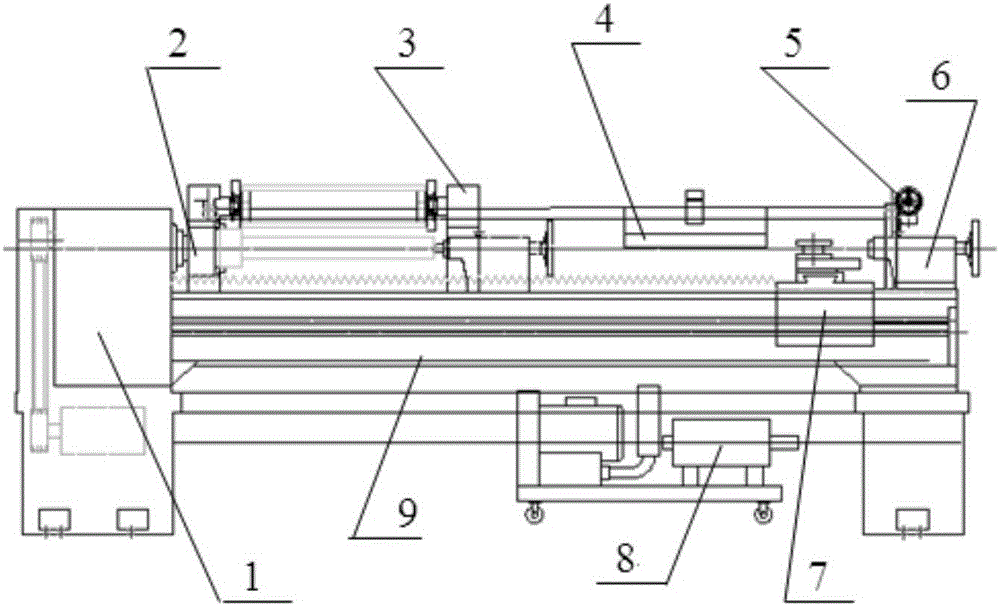

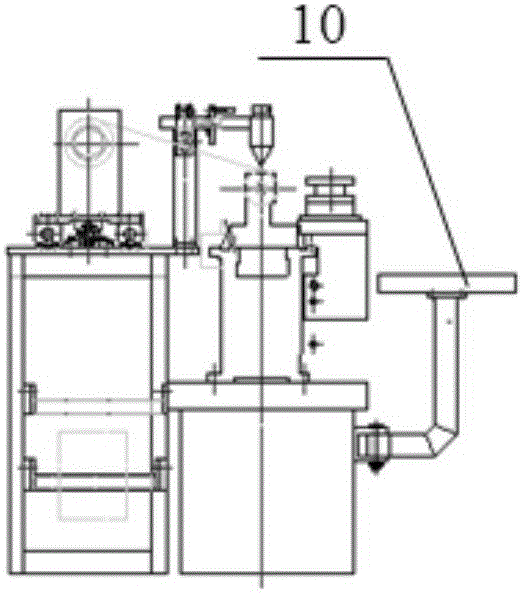

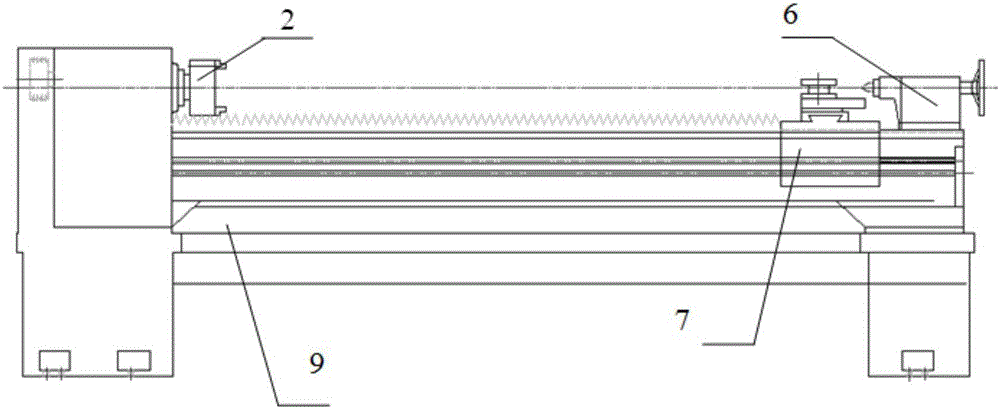

[0035] Such as Figure 1a and 1b As shown, it is a generator conductive screw insulation wrapping device, and the generator conductive screw insulation wrapping device includes a bed 9, such as figure 2 As shown, the bed 9 is provided with a wrapping head 2 and a thimble 6, and the generator conductive screw is arranged between the wrapping head 2 and the thimble 6. The wrapping head 2 can drive the generator conductive screw to rotate under the drive of the driving device 1, and the bed The body 9 is also provided with an insulating material tensioning device 3 and an insulating material heating device. The insulating material heating device includes an air outlet 4, and the insulating material tensioning device 3 is arranged in front of the wrapping part to be insulated on the conductive screw of the generator. On the side or rear side, the air outlet 4 of the insulating material heating device is arranged on the upper side of the wrapping part to be insulated. The bed 9 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com