An Adaptive LED Driving Circuit

An LED driving and self-adaptive technology, applied in the direction of electric lamp circuit layout, electric light source, lighting device, etc., can solve the problems of reduced design flexibility of the whole lamp, small LED conduction angle, large harmonic distortion, etc., to avoid electromagnetic interference. Problems, control method circuit is simple, harmonic distortion reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

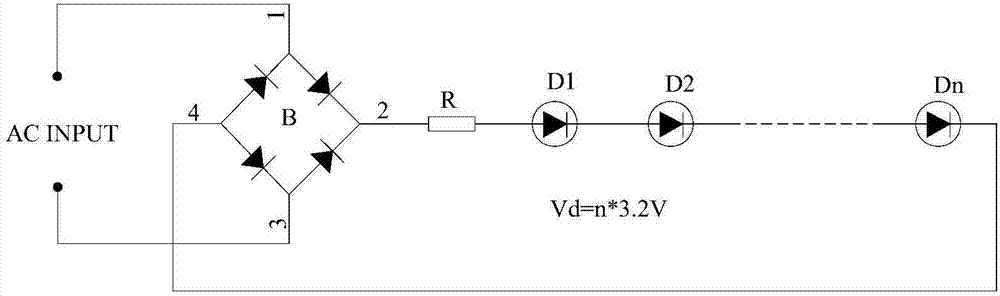

[0040] Please refer to figure 2 As shown, since the voltage of a single LED is generally about 3.2V, this case uses multiple low-voltage LEDs in series or directly uses high-voltage lamp beads to form an LED series circuit. A single high-pressure lamp is an LED string.

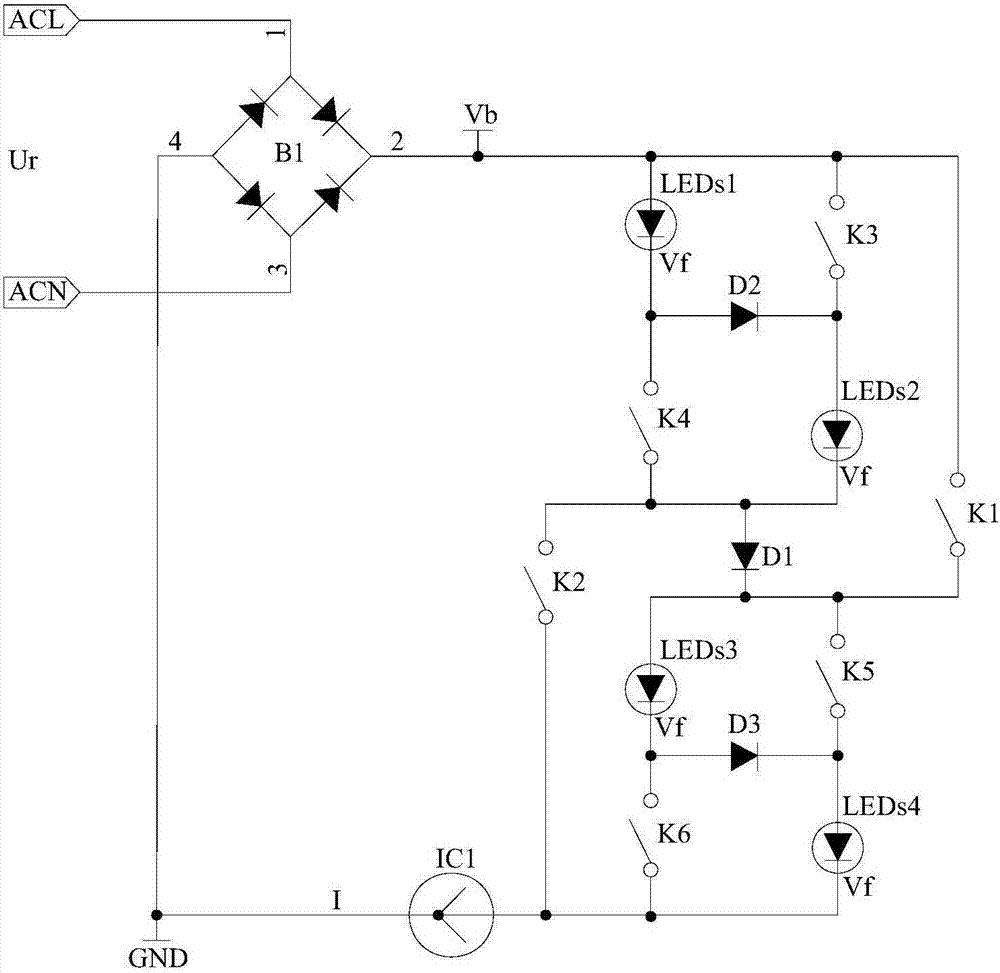

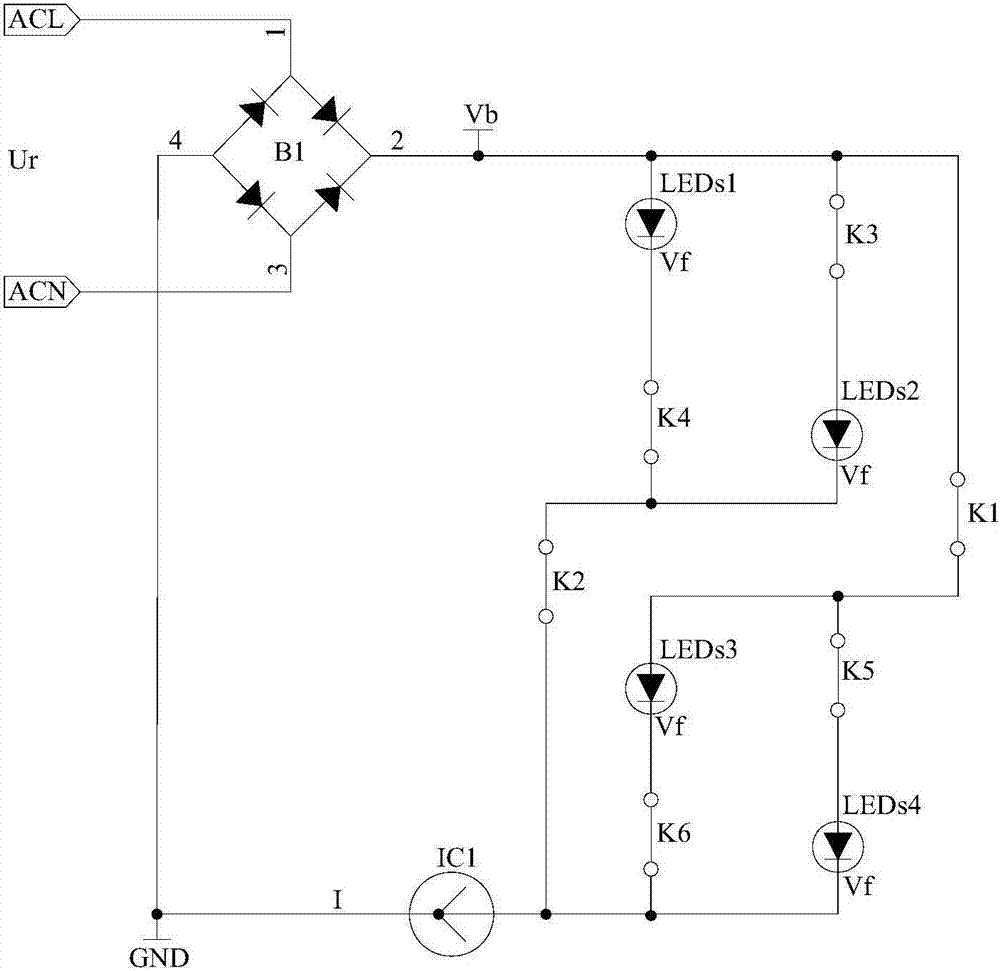

[0041] The principle diagram of this case is as follows:

[0042] figure 2 Among them, B1 is a rectifier bridge stack, which rectifies the mains power into a fluctuating DC voltage Vb; LEDs1 to LEDs4 are four LED strings, and their total forward voltage is Vf; K1 to K6 are 6 current control switches composed of circuits. It is a normally closed switch, the state of the switch is controlled by the current of the circuit, the switch is closed when the current is small, and the switch is open when the current is large, and the trigger current of its disconnection can be controlled by the parameter value of the component, and the parameter value of the circuit component is set so that The trigger current of K...

Embodiment 2

[0069] Embodiment 2 is to increase one or more current control sub-units on the basis of embodiment 1. When adding a current control sub-unit, a structure consisting of 6 LED strings is formed, and the added current control sub-units can be visualized In order to be placed between the two current control subunits of Embodiment 1, a diode is connected to the input and output ends of the added current control subunit respectively, so as to be connected to the two current control subunits of Embodiment 1 respectively , at the same time, a current control switch is also connected in series at the input and output terminals of the added current control subunit, please refer to Figure 10 As shown, the trigger currents of the current control switches are as follows from small to large: K1 (K2, K15, K16), K3 (K4), K17 (K18), K5 (K6). The specific working principle is similar to that of the first embodiment, and will not be repeated here. Of course, if more current control subunits a...

Embodiment 3

[0071] The third embodiment is to add one or more current control circuits on the basis of the first embodiment, please refer to Figure 11 As shown, when adding a current control circuit, the added current control circuit is connected in parallel with the previous current control circuit, and then a current control switch K13 is added at the input end of the two, and a current control switch K13 is connected in series at the output end of the previous current control circuit The current control switch K14, at the same time, a diode D7 is connected between the output terminal of the previous current control circuit and the added current control circuit, so as to expand into a structure composed of 8 LED strings, the current control switches K13, K14 and the current control The switch K1 etc. have the same structure. The trigger current of the current control switch is K1 (K2, K7, K8), K3 (K4), K5 (K6), K9 (K10), K11 (K12) from small to large, and the trigger current of the cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com