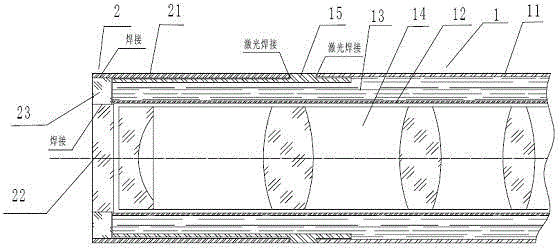

Structure of hard-tube anti-fog endoscope

An endoscope and anti-fog technology, which is applied in the field of minimally invasive medical treatment, can solve the problems of reducing the optical imaging quality of the endoscope system, affecting the imaging quality of the endoscope system, etc., and achieves good window heat transfer performance and good infrared absorption performance. , to ensure the effect of image quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

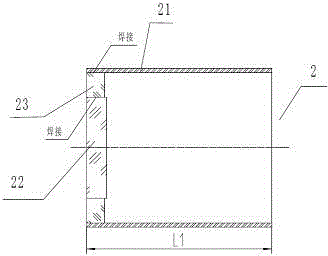

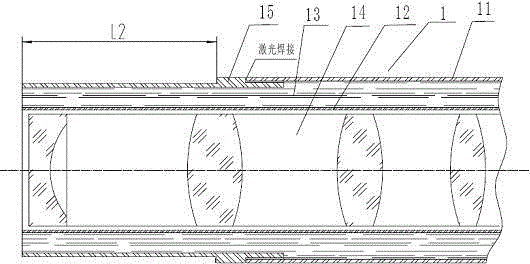

[0018] The matching gap between the outer diameter of the left and right sides of the connecting ring 15 and the inner diameter of the outer tube 11 is 0.01 mm, and the matching gap between the inner diameter of the sleeve 21 and the left outer diameter of the connecting ring 15 is 0.01 mm. The inner circle of the sleeve 21 is metallized within a range of 3 mm from the left end face to the left end face, the thickness of the optical window 22 is 0.7 mm, and the diameter of the metallized outer circle is 0.07 mm smaller than the inner diameter of the inner tube 12 , the thickness of the optical fiber window 23 is 0.65mm, the metallized outer diameter of the optical fiber window 23 and the metallized inner diameter of the sleeve 21 cooperate with a gap of 0.01mm, the metallized optical fiber window 23 The matching gap between the inner diameter of the optical window plate 22 and the metallized outer diameter of the optical window plate 22 is 0.01 mm, the value of L1 of the sleeve...

Embodiment 2

[0021] The matching gap between the outer diameter of the left and right sides of the connecting ring 15 and the inner diameter of the outer tube 11 is 0.02 mm, and the matching gap between the inner diameter of the sleeve 21 and the left outer diameter of the connecting ring 15 is 0.02 mm. The inner circle of the sleeve 21 is metallized within a range of 5 mm from the left end face to the left end face, the thickness of the optical window 22 is 1 mm, and the diameter of the metallized outer circle is 0.1 mm smaller than the inner diameter of the inner tube 12, The thickness of the optical fiber window 23 is 0.9mm, the metallized outer diameter of the optical fiber window 23 and the metallized inner diameter of the sleeve 21 have a matching clearance of 0.02mm, and the metallized outer diameter of the optical fiber window 23 is The matching gap between the inner diameter and the metallized outer diameter of the optical window 22 is 0.02 mm, the value of L1 of the sleeve 21 is 2...

Embodiment 3

[0023] The matching gap between the outer diameter of the left and right sides of the connecting ring 15 and the inner diameter of the outer tube 11 is 0.01 mm, and the matching gap between the inner diameter of the sleeve 21 and the left outer diameter of the connecting ring 15 is 0.01 mm. The inner circle of the sleeve 21 is metallized within a range of 4 mm from the left end face to the left end face, the thickness of the optical window 22 is 0.3 mm, and the diameter of the metallized outer circle is 0.05 mm smaller than the inner diameter of the inner tube 12 , the thickness of the optical fiber window 23 is 0.25mm, the metallized outer diameter of the optical fiber window 23 and the metallized inner diameter of the sleeve 21 are matched with a gap of 0.01mm, the metallized optical fiber window 23 The fit gap between the inner diameter of the optical window plate 22 and the metallized outer diameter of the optical window plate 22 is 0.01 mm, the value of L1 of the sleeve 21...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com