Customized personalized 3D printing simulated prosthetic finger

A 3D printing and prosthetic finger technology, applied in artificial arms and other directions, can solve the problems of tubular bones that are not completely suitable for fingers, unable to greatly improve the patient's hand function, unable to achieve hand function and appearance, etc., to save medical costs, raw materials and The effect of operating advanced science and strengthening environmental protection benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

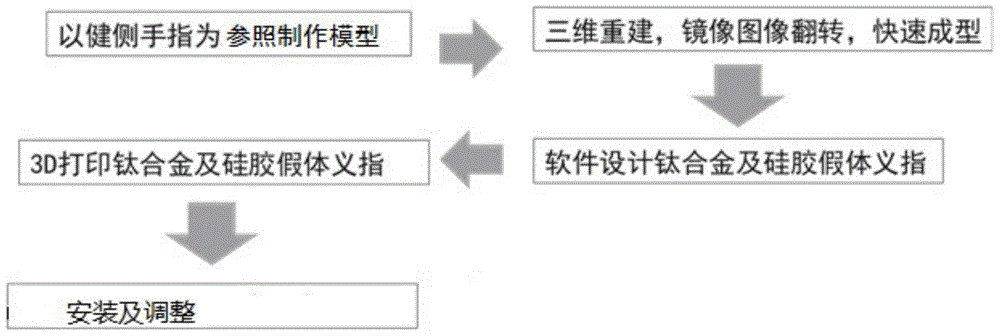

[0023] Such as figure 1 As shown, this embodiment includes the following steps:

[0024] (1) Information acquisition and three-dimensional reconstruction: CT scanning was used to scan both hands, and then the two CT tomographic image data were identified by MIMICS software, and then processed by Surfacer 9.0 (Imageware Company, USA) reconstruction software to observe the tomography and reconstructed finger phalanx, The degree of missing phalanx and the inner diameter of stump bone were calculated, so as to calculate the size and shape of the metal implant, and the size and shape of the metal bone of the prosthetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com