Ni-containing molecular sieve adsorbent and preparation method thereof

A technology of molecular sieves and adsorbents, applied in the field of Ni-containing molecular sieve adsorbents and their preparation, can solve the problems of low adsorption capacity, poor regeneration stability, and low purification precision of adsorbents, and achieve good reproducibility and good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

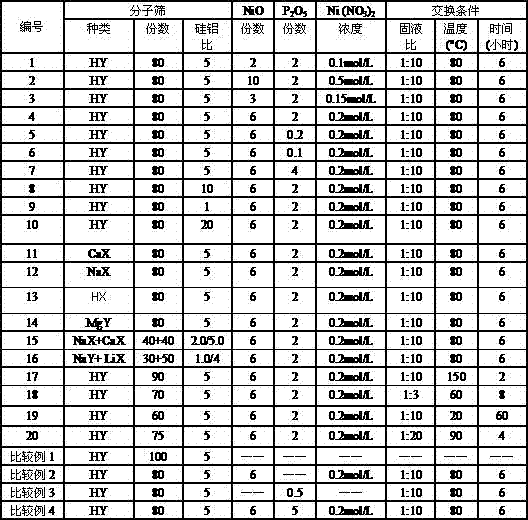

[0025] Contains NiO and P 2 o 5 The preparation process of the ion-exchange modified HY molecular sieve adsorbent is as follows. First, accurately weigh

[0026] 10 g HY molecular sieve raw powder with a silicon-aluminum ratio of 5. Subsequently, Ni(NO 3 ) 2 Solution 100 ml. Thereafter, 86% by weight of H was continuously added dropwise 3 PO 4 solution (density 1.6 g / ml), make H 3 PO 4 The molar concentration is 0.1mol / L. Add the accurately weighed HY molecular sieve raw powder to the above 100 ml Ni (NO 3 ) 2 and PO 4 3- In the solution, that is, according to the solid-liquid ratio of 1:10, at 80 o C, fully stirred, exchanged for 6h. Filter and rinse with deionized water. Repeat the above exchange operation three times. The exchanged molecular sieve precursor was obtained after drying. Form into pieces, dry naturally, 550 in the air o C, baked for 2 hours. Grind and sieve to get the adsorbent particles with a diameter of 830-1700 μm, at 300 o C drying unt...

Embodiment 2

[0029] Contains NiO and P 2 o 5 The preparation process of the ion-exchange modified HY molecular sieve adsorbent is as follows. First, accurately weigh 10 g of HY molecular sieve raw powder with a silicon-aluminum ratio of 5. Subsequently, Ni(NO 3 ) 2 Solution 100 ml. Thereafter, 86% by weight of H was continuously added dropwise 3 PO 4 solution (density 1.6 g / ml), make H 3 PO 4 The molar concentration is 0.1mol / L. Add accurately weighed 10g HY molecular sieve raw powder to the above 100 ml Ni (NO 3 ) 2 and PO 4 3- In the solution, that is, according to the solid-liquid ratio of 1:10, at 80 o C, fully stirred, exchanged for 6h. Filter and rinse with deionized water. Repeat the above exchange operation three times. The exchanged molecular sieve precursor was obtained after drying. Form into pieces, dry naturally, 550 in the air o C, baked for 2 hours. Grind and sieve to get the adsorbent particles with a diameter of 830-1700 μm, at 300 o C drying until the ...

Embodiment 3

[0032] Containing 3 parts by weight of NiO and 2 parts by weight of P 2 o 5 , The preparation process of the ion-exchange modified HY molecular sieve adsorbent containing 80 parts by weight of HY is as follows. First, accurately weigh 10 g of HY molecular sieve raw powder with a silicon-aluminum ratio of 5. Subsequently, Ni(NO 3 ) 2 Solution 100 ml. Thereafter, 86% by weight of H was continuously added dropwise 3 PO 4 solution (density 1.6 g / ml), make H 3 PO 4 The molar concentration is 0.1 mol / L. Add accurately weighed 10g HY molecular sieve raw powder to the above 100 ml Ni (NO 3 ) 2 and containing PO 4 3- In the solution, that is, according to the solid-liquid ratio of 1:10, at 80 o C, fully stirred, exchanged for 6h. Filter and rinse with deionized water. Repeat the above exchange operation three times. The exchanged molecular sieve precursor was obtained after drying. Form into pieces, dry naturally, 550 in the air o C, baked for 2 hours. Grind and siev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com