7-series aluminum alloy extrusion die

An extrusion die, aluminum alloy technology, applied in the direction of metal extrusion die, can solve the problems of large deformation resistance of metal, poor fluidity, large force on the die, etc., to reduce the degree of elastic deformation, reduce the flow resistance of the alloy, and increase the resistance The effect of force area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

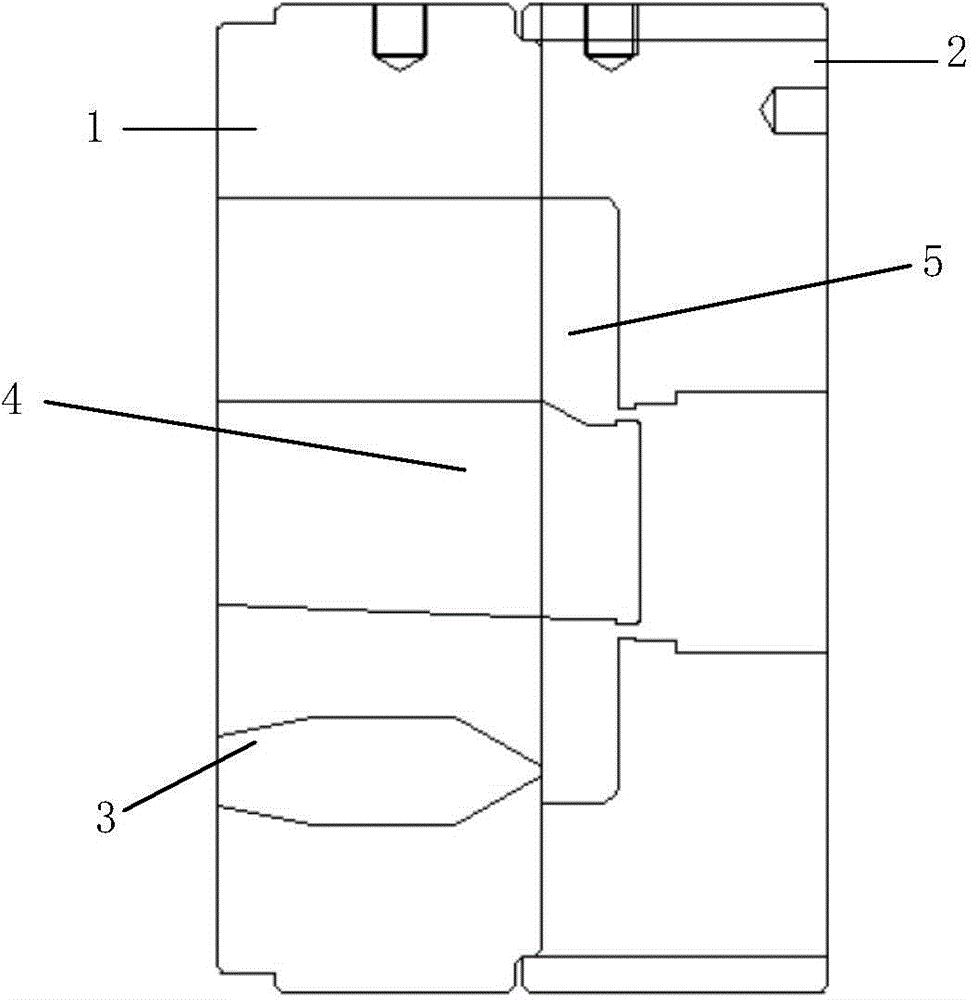

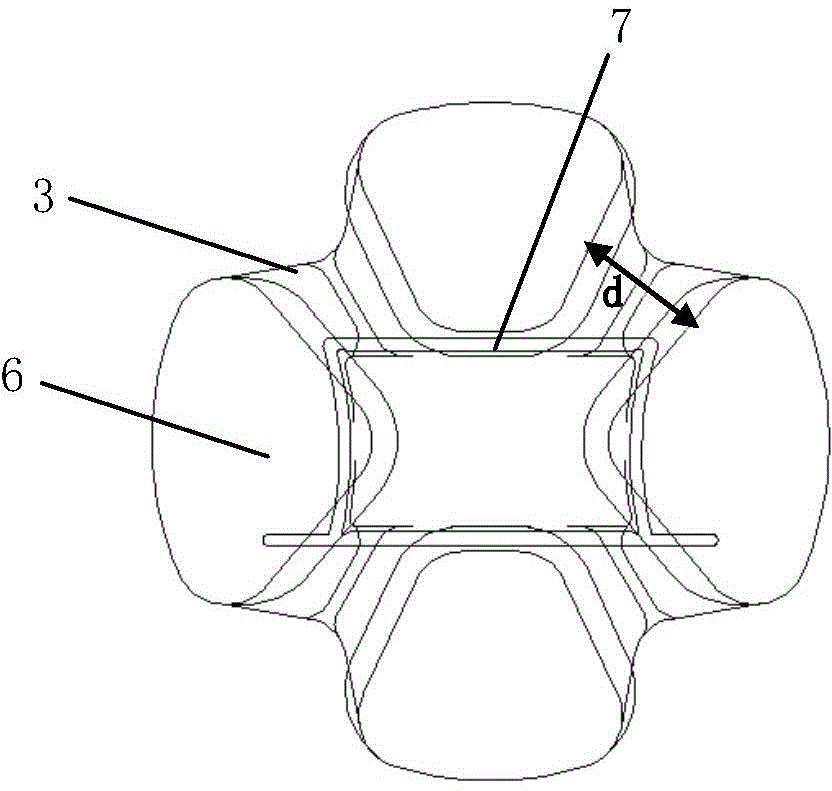

[0034] Such as Figure 4 As shown, the extrusion die of the present invention has a size of ¢260*200, and its structure is basically the same as the extrusion die of the comparative example. It also includes an upper die 1 and a lower die 2, wherein the upper die 1 is provided with a shunt bridge 3 and The mold core 4 and the lower mold 2 are provided with a welding chamber 5 and a mold hole 7. Diversion holes 6 are arranged on the inner side of the diversion bridge 3, and the material flow is divided into multiple strands through the diversion holes 6. After the streams are combined in the welding chamber 5 for welding, they are extruded from the die hole 7 to obtain the profile.

[0035] The extrusion die also includes positioning pins for limiting the upper and lower molds and screws 8 for connecting and fixing the upper mold and the lower mold.

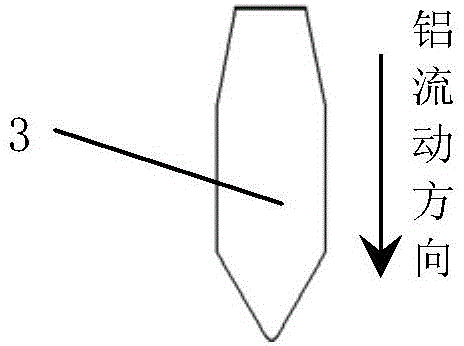

[0036] The difference between the extrusion die of this embodiment and the comparative example is that Figure 5 As shown, in the ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap