Material discharging mechanism of core column welding machine

A welding machine and core column technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of unfavorable large-scale production and restriction of production efficiency, achieve compact structure, reduce manpower and material resources, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

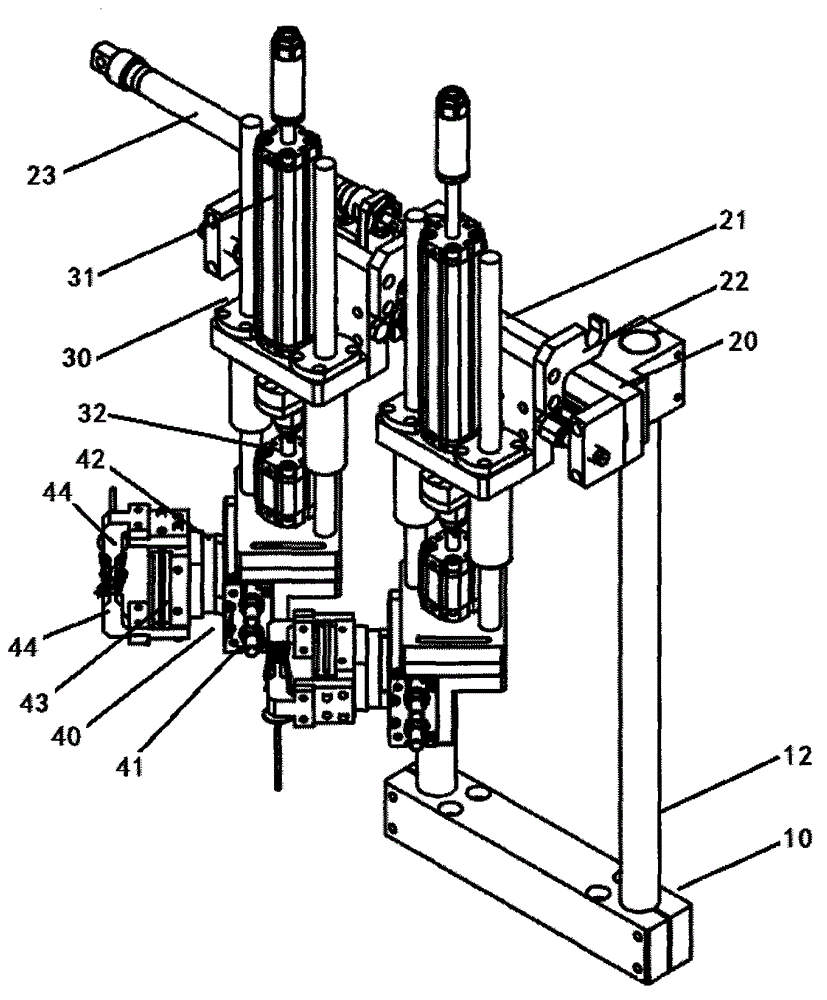

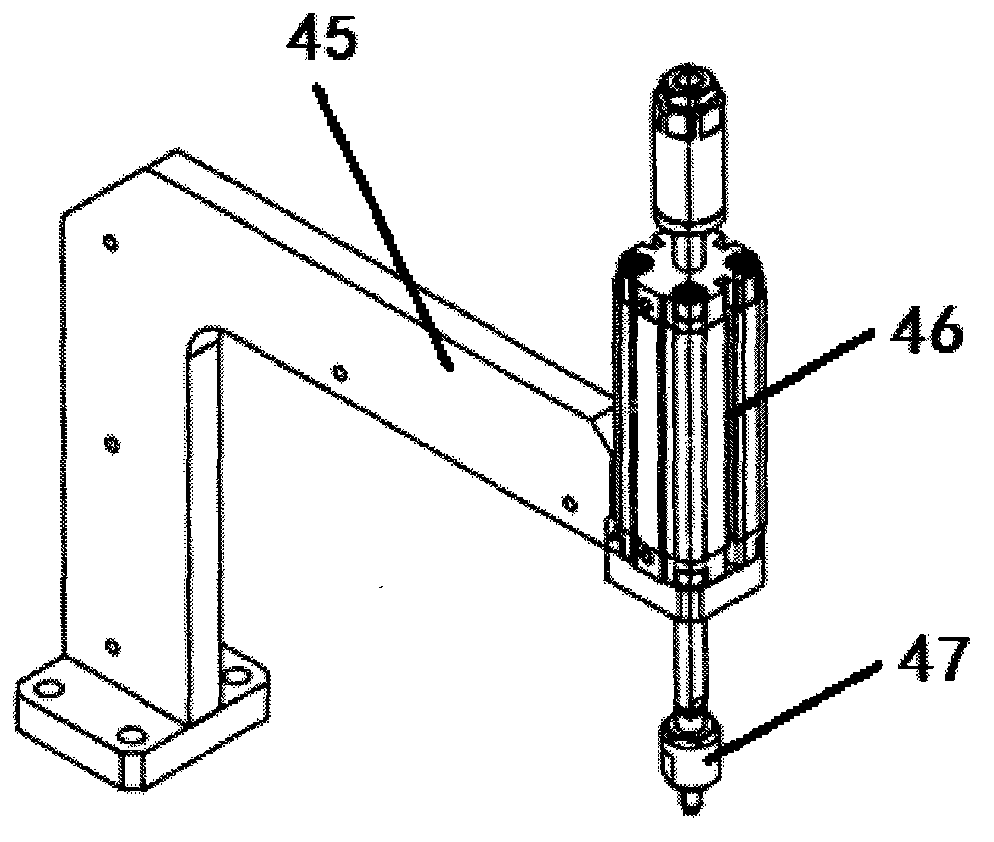

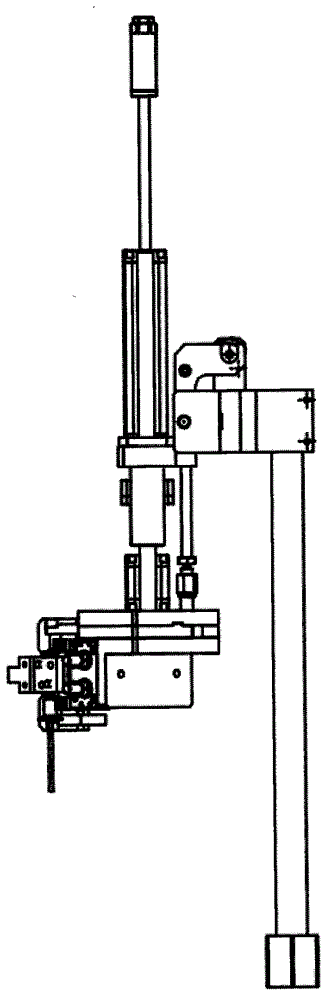

[0018] Such as Figure 1~4 As shown, the unloading mechanism of the stem welding machine described in this embodiment includes a bracket assembly 10, a shifting assembly 20, a lifting assembly 30, a clamping assembly 40 and a PLC controller (not shown in the figure). The displacement assembly 20 is installed on the support assembly 10, and the displacement assembly 20 includes a horizontal guide rail 21 arranged on the vertical support 12 of the support assembly 10, and one or more sliders are installed on the horizontal guide rail 21. seat 22, and a displacement cylinder 23 for driving the slider mounting base 22 to move on the horizontal guide rail; the lifting assembly 30 is installed on the slider mounting base 22, and the lifting assembly 30 includes The first lifting cylinder 31 on the slider mounting base 22, and the second lifting cylinder 32 connected to the lower end of the telescopic rod of the first lifting cylinder 31; the lower end of the telescopic rod of the se...

Embodiment 2

[0020] Since the compression universal head in Embodiment 1 needs to have relatively high hardness, as well as certain toughness and strength, it usually needs to be made of tool steel. In this embodiment, the compression universal head is formed by casting, and its chemical composition is as follows: C: 0.80-0.92wt%, Cr: 1.36-1.55wt%, Mn: 0.42-0.55wt%, Si: 0.10 ~0.15wt%, V: 0.12~0.15wt%, Ti: 0.02~0.03wt%, Ni≤0.20wt%, Cu≤0.20wt%, P≤0.030wt%, S≤0.030wt%, the balance is Fe and Unavoidable impurities; after casting, heat the billet to 980-1020°C for 2-3 hours, then quench it in quenching oil at 120-150°C for 30-35 seconds, and then heat it to 350-380°C for heat preservation After 5-5.5 hours, put it into a sodium nitrate solution with a temperature of 60-80° C. and a concentration of 10 wt % for quenching treatment for 15-20 seconds. The tensile strength of the compacted universal head obtained through the above-mentioned casting and post-treatment can reach 1520-1700 MPa, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com