Multi-layer structured cover plate for improving drilling position precision of flexible PCB (printed circuit board)

A flexible printed circuit and hole position accuracy technology, applied in metal processing and other directions, can solve the problems of inability to obtain drilling hole position accuracy and quality, affecting the hole position accuracy of the flexible board, and bending deformation of the flexible board. The effect of drilling hole position accuracy, reducing slippage in drilling, and reducing compression deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

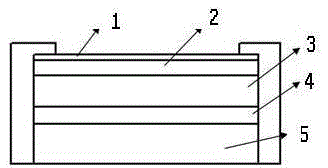

[0013] The structure diagram of the present invention is as image 3 As shown, the multi-layer structure cover plate of the present invention that improves the accuracy of the drilling hole position of the flexible printed circuit board includes a drilling guide layer 1 and a hard cover plate 3, and the drilling guide layer 1 is arranged on the top of the hard cover plate 3 noodle. In this embodiment, the above-mentioned drilling guide layer 1 is attached to the substrate 2 to form a soft cover layer.

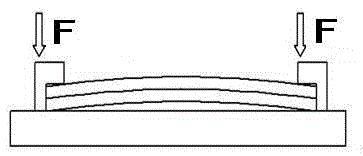

[0014] The soft cover layer composed of the above-mentioned drilling guide layer 1 attached to the substrate 2 is a thin layer with a thickness of less than 0.5mm. The soft cover layer is a material that is easy to drill into, and its function is to guide the drilling, reducing the figure 1 The amount of deformation shown increases the overall CPK value of flexible plate drilling.

[0015] The above-mentioned substrate 2 is an aluminum substrate. The thickness of the substra...

Embodiment 2

[0023] The structure diagram of the present invention is as Figure 4 As shown, the multi-layer structure cover plate of the present invention that improves the accuracy of the drilling hole position of the flexible printed circuit board includes a drilling guide layer 1 and a hard cover plate 3, and the drilling guide layer 1 is arranged on the top of the hard cover plate 3 noodle. The difference between this embodiment and Embodiment 1 is that no substrate 2 is provided.

[0024] The drilling guide layer 1 provided on the hard cover plate 3 is a thin layer with a thickness of less than 0.5mm. The drilling guide layer 1 is a material that is easy to drill into, and its function is to guide the drilling, reducing the figure 1 The amount of deformation shown increases the overall CPK value of flexible plate drilling.

[0025] In this embodiment, the above-mentioned drilling guide layer 1 and hard cover plate 3 can be stacked in multiple layers. In order to improve the drilli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com