Buoyancy separation device for automotive non-metal shredded waste

A separation device, non-metallic technology, applied in wet separation, solid separation, plastic recycling, etc., to achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

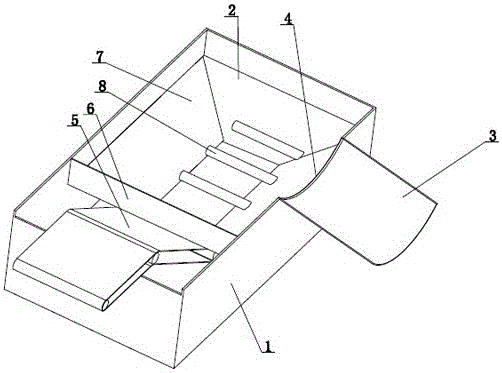

[0028] Such as figure 1 As shown, a buoyancy separation device for automobile non-metal crushed waste provided in this embodiment includes a device main body 1, a water tank 2 is provided on the device main body 1, and a counter-floating water tank is also provided on the above-mentioned device main body 1. 2. The first separation mechanism for draining and collecting the non-metallic scrap of automobiles on the liquid level line and the second separation mechanism for separating the metal impurities from the non-metallic scrap of automobiles sinking in the bottom of the tank 2, and then draining and collecting them.

[0029] The specific structure of both the above-mentioned first separation mechanism and the second separation structure is: the first separation mechanism includes a first diversion plate 3, the vertical cross section of the first diversion plate 3 is an arc-shaped structure, and in the water tank 2 A first arc-shaped overflow collecting port 4 consistent with ...

Embodiment 2

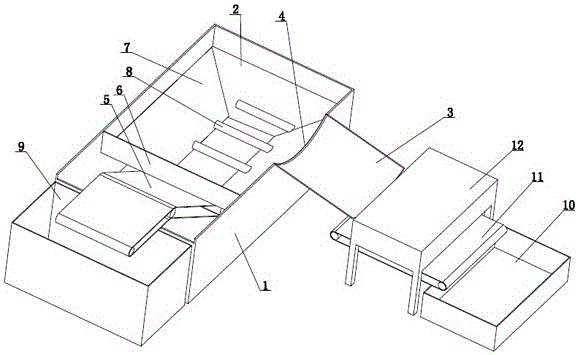

[0031] A kind of buoyancy separation device of automobile non-metal crushing waste provided by the present embodiment, its general structure is consistent with embodiment 1, as figure 2 shown, but the buoyancy separation device also includes a first collection box 9, a second collection box 10, a first horizontal conveyor belt device 11 and a first drying device 12, wherein the above-mentioned ascending conveyor belt device 5 After the high end is led out of the water tank 2, it extends into the first material receiving box 9, and the inclined downward port on the side of the first diversion plate 3 extends to the first horizontal conveyor belt device 11, and the first horizontal conveyor belt device 11 runs through The first drying device 12 extends to the top of the second receiving box 10 , and the drying port of the first drying device 12 faces the above-mentioned first horizontal conveyor belt device 11 .

[0032] The relatively high-density automotive non-metallic crush...

Embodiment 3

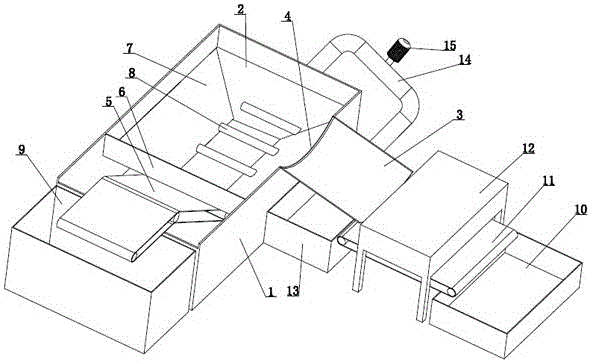

[0034] The buoyancy separation device of a kind of automobile non-metal pulverized waste material that present embodiment provides, its general structure is consistent with embodiment 2, as image 3 As shown, but the first diversion plate 3 described in this embodiment is an orifice plate, a circulating water tank 13 is added below the first diversion plate 3, and a water circulation pipeline 14 is connected to the above-mentioned circulating water tank 13. The water circulation pipeline The other end is connected on the wall of the water tank 2, and a water circulation pump 15 is added on the water circulation pipeline 14.

[0035] The water overflowing from the water tank 2 can conveniently re-enter the water tank 2 for repeated use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com