A winding method for frequency-vibration insecticidal lamp high-voltage power grid

A frequency-vibration insecticidal lamp and high-voltage power grid technology, which is applied in the field of insecticidal lamp high-voltage power grid winding, can solve the problems of high cost, complicated process, and weakened insulation tube strength, etc., and achieve low cost, simple process, and tight grid lines. resulting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

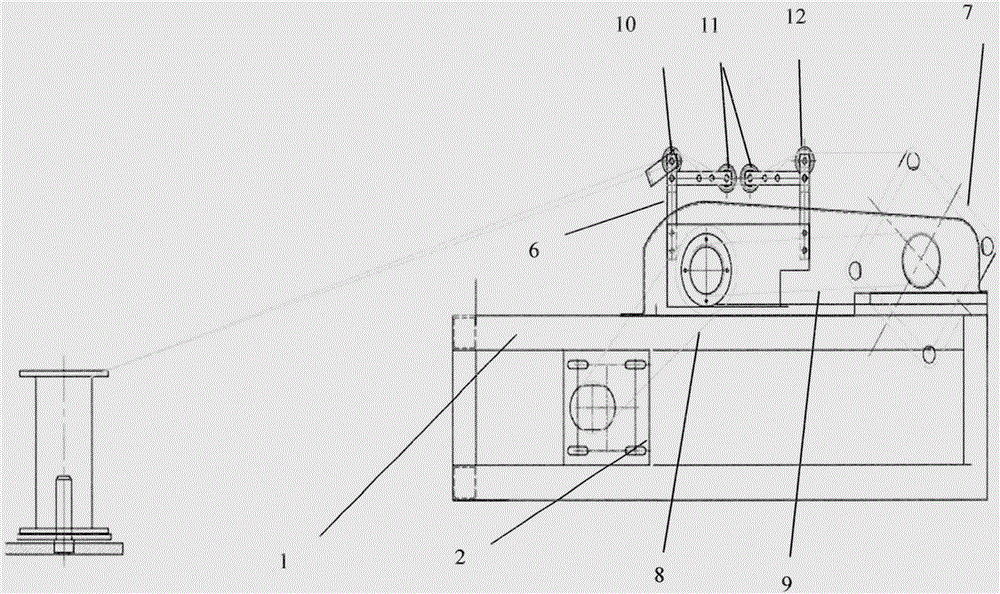

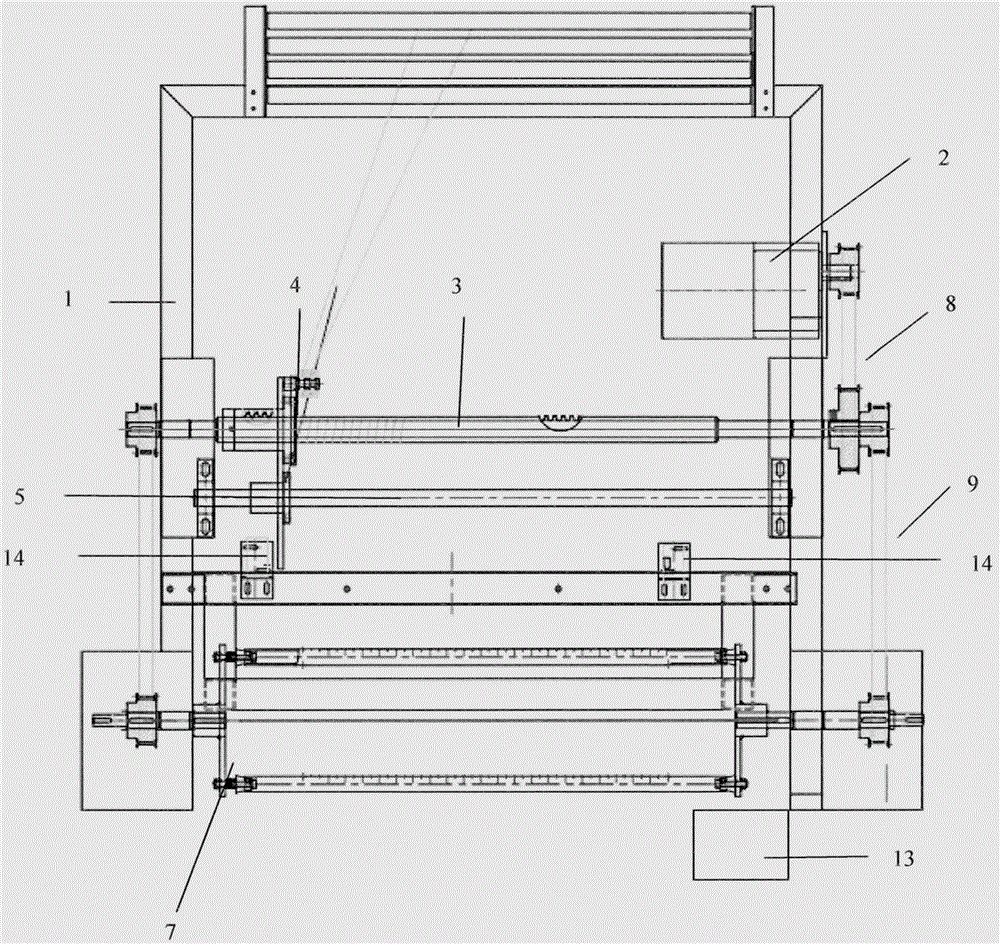

[0017] The winding method for the high-voltage power grid of the frequency-vibration type insecticidal lamp is specifically a method for realizing the winding of the high-voltage power grid of the insecticidal lamp by using a specially designed spiral winding machine. This spiral winding machine includes a bracket 1, a motor 2 mounted on the bracket, a screw 3 installed horizontally on the bracket, a nut 4 matched with the thread of the screw 3, a guide rod 5 installed on the bracket parallel to the screw rod, The pulley assembly 6, the support frame 7 on which the grid bracket is placed, the electrical control box 13, and the limit stop switch 14 installed on the bracket are installed on the screw rod and the guide rod. A set of positioning pulleys 10 , line tightening pulleys 11 and steering pulleys 12 are mounted on the pulley assembly 6 . A grid support composed of four insulating columns and upper and lower plastic fixing plates is placed on the support frame, the motor a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com