Coordinated control method of track and crane for handling system of semiconductor production line

A handling system and production line technology, applied in the direction of transportation and packaging, load hanging components, etc., to achieve the effect of improving the degree of automation and avoiding congestion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below with reference to the drawings and embodiments.

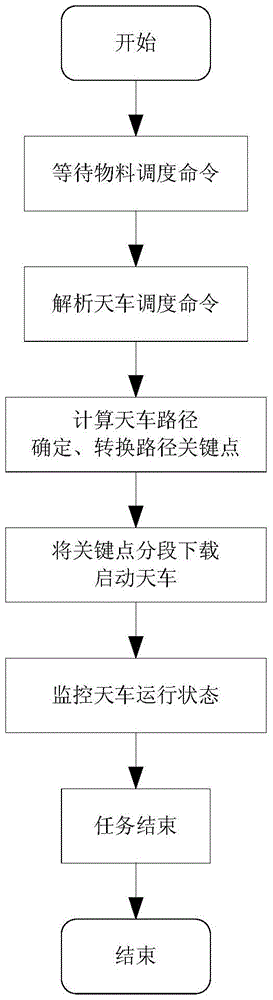

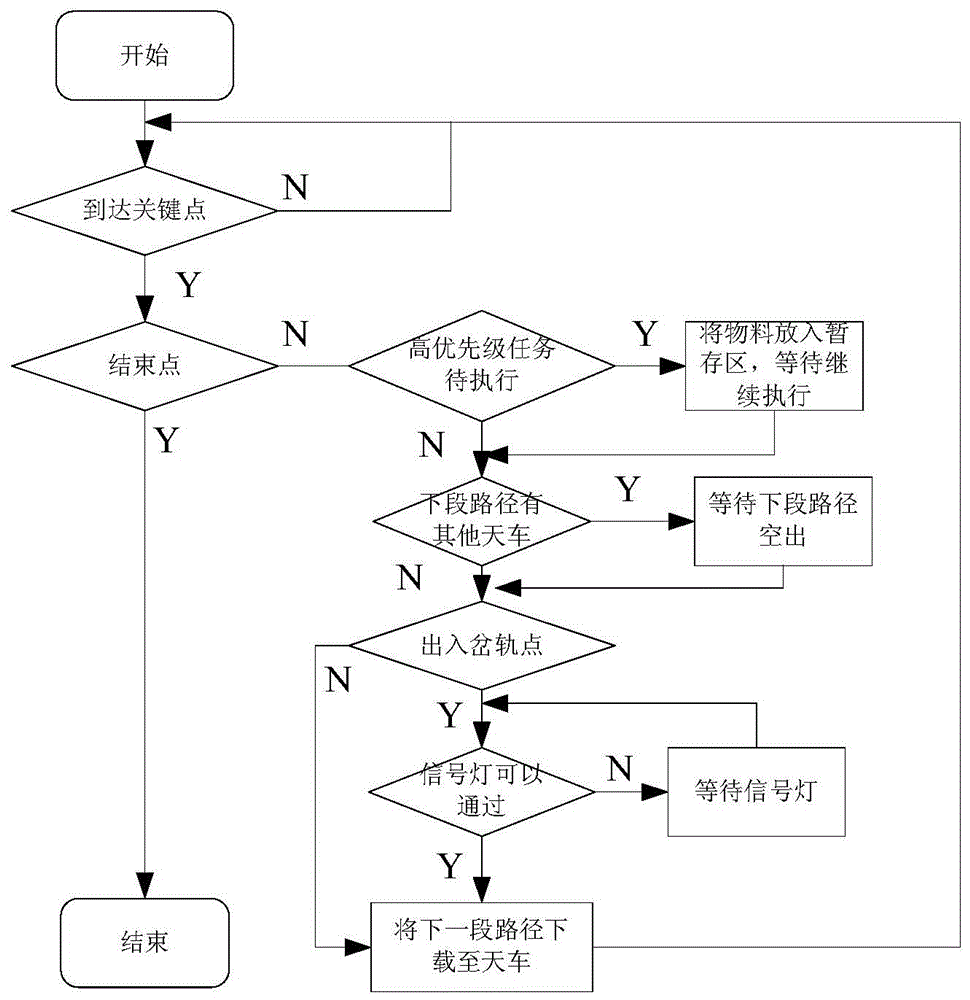

[0020] See attached figure 1 , Is the system control flowchart of the present invention. A method for coordinated control of track and crane for semiconductor production line handling system, including the following steps:

[0021] The track on which the crane runs consists of straight rails, curved rails, switch rails, and temporary material storage areas. The straight rails and switch rails are affixed with barcodes that can determine the position of the crane in the track; the track laying is divided into regional tracks and sections Track (in-area track is an area composed of closed track connections, and processing equipment is placed within the scope of the track in the area to determine the processing area of a certain process or process; the inter-area track connects the independent regional tracks together When the material needs to be transported fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com