A microwave explosion-proof drying recovery system for preparing airgel materials

A recovery system and aerogel technology, applied in the direction of silica, inorganic chemistry, non-metallic elements, etc., can solve the problem of inability to make aerogels with integrity and integrity, reduced specific surface area and porosity, and large gel shrinkage To achieve the effect of accelerating volatilization and recovery, fast drying speed and high energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited thereto.

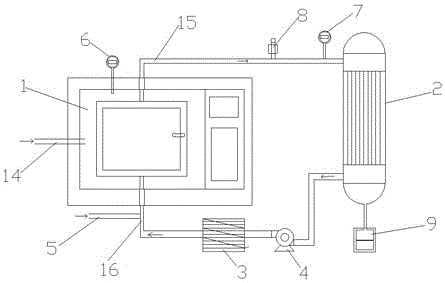

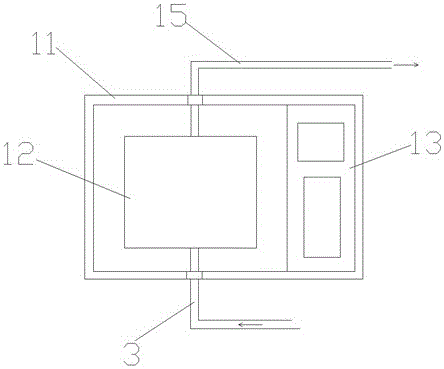

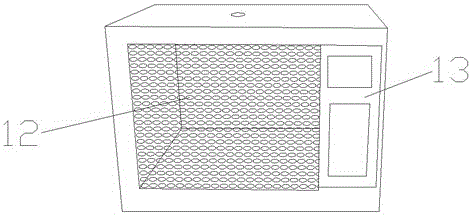

[0024] Such as Figure 1-Figure 5 As shown, the microwave explosion-proof drying recovery system used to prepare airgel materials in the present invention includes a microwave heating device 1, a condenser 2 and a heat exchanger 3, and the microwave heating device 1 includes a microwave device box 11, a sealed container 12 and a microwave heating device 1. The control panel 13, the airtight container 12 and the microwave control panel 13 are located in the microwave equipment box body 11, the microwave equipment box body 11 is connected with a protective gas input pipe 14, and the airtight container 12 is located in the protective gas input pipe 14 and the microwave control panel 13 In between, the atmosphere with low oxygen content can be formed in the space of the microwave heating equipment 1 after th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com