A method for manufacturing a sealing cover for the observation hole of the fire path of a carbon anode roasting furnace

A carbon anode and a production method technology, which are applied in the field of carbon roasting furnace body and its materials, can solve the problems of low high temperature flexural strength, poor thermal shock stability, poor use effect, etc., and achieve improved thermal insulation and sealing effect, high temperature resistance sealing The effect of good performance and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

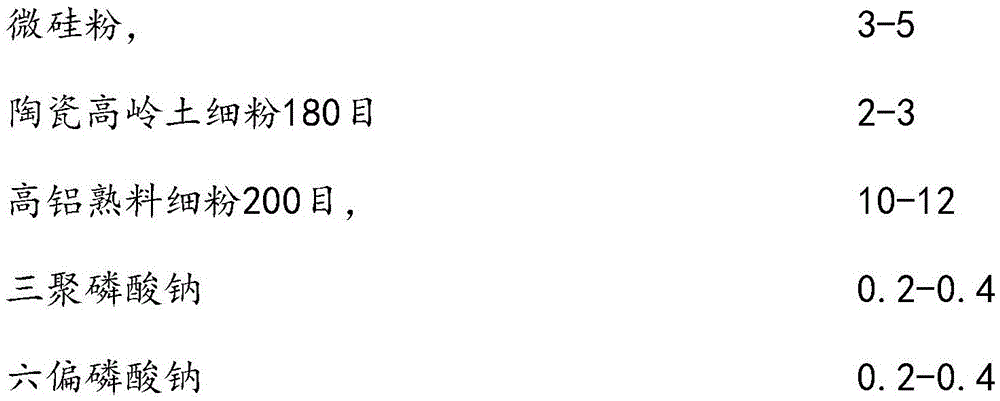

[0013] Embodiment one: select the following raw material components in parts by weight:

[0014]

[0015] After the aggregates and additives are formulated according to the above-mentioned parts by weight, they are added to 6 times the parts by weight of the high-temperature-resistant silicon solvent. After the negative pressure mold of the sealing cover of the wall, the liquid solvent is sucked away by the vacuum pump through the gap of Φ2mm-Φ5mm in the inner wall of the interlayer and the pressure difference to form a sealing cover; after natural air drying for 96 hours, and then drying at 150°C-200°C for 72 hours The finished sealing cap is finished.

Embodiment approach 2

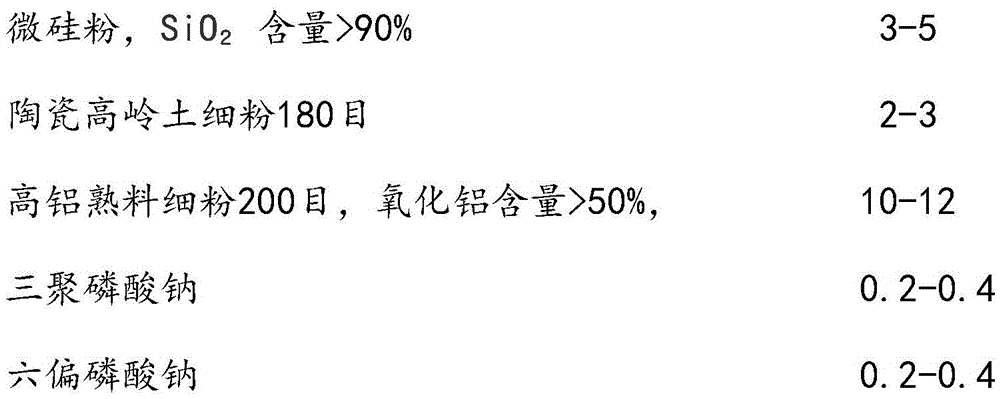

[0016] Embodiment two: select the following raw material components in parts by weight:

[0017]

[0018]

[0019] After the aggregates and additives are formulated according to the above-mentioned parts by weight, they are added to 7 times the parts by weight of the high-temperature-resistant silicon solvent. After the negative pressure mold of the sealing cover of the wall, the liquid solvent is sucked away by the vacuum pump through the gap of Φ2mm-Φ5mm in the inner wall of the interlayer and the pressure difference to form a sealing cover; after natural air drying for 96 hours, and then drying at 150°C-200°C for 72 hours The finished sealing cap is finished.

Embodiment approach 3

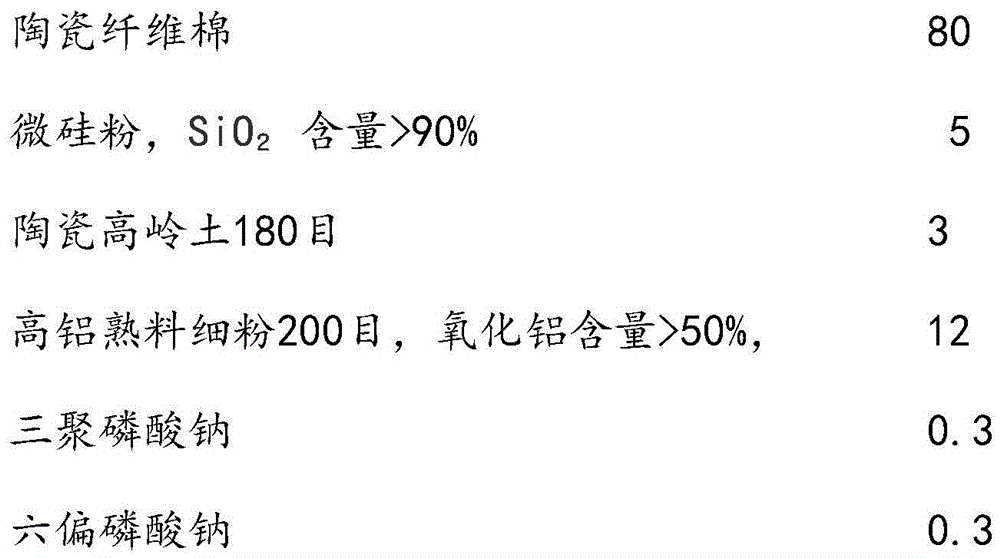

[0020] Embodiment three: select the following raw material components in parts by weight:

[0021]

[0022] After the aggregates and additives are formulated according to the above-mentioned parts by weight, they are added to 8 times the parts by weight of the high-temperature-resistant silicon solvent. After the negative pressure mold of the sealing cover of the wall, the liquid solvent is sucked away by the vacuum pump through the gap of Φ2mm-Φ5mm in the inner wall of the interlayer and the pressure difference to form a sealing cover; after natural air drying for 96 hours, and then drying at 150°C-200°C for 72 hours The finished sealing cap is finished.

[0023] The physical and chemical performance index of a kind of carbon anode baking furnace flue observation hole sealing cover is as follows:

[0024]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com