Premixed polyether, raw material composition, polyurethane foam, and preparation method and application thereof

A raw material composition and a technology of combining polyether, which is applied in the field of polyurethane, can solve the problems of poor safety of composite lifebuoys, low closed cell rate of polyurethane foam, and poor foam strength, and achieve excellent dimensional stability, low water absorption, and impact resistance. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

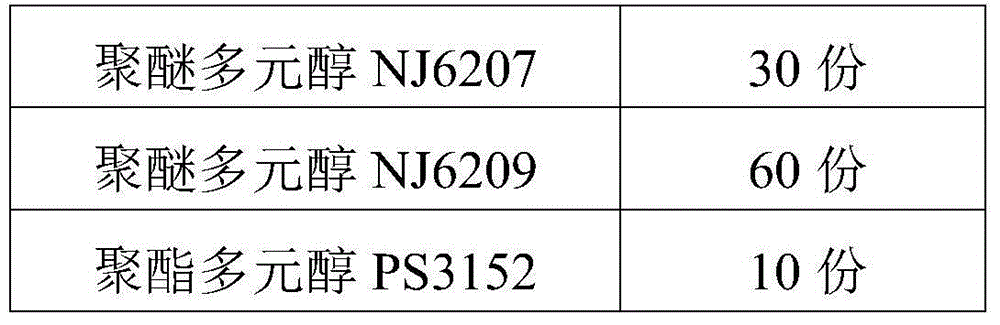

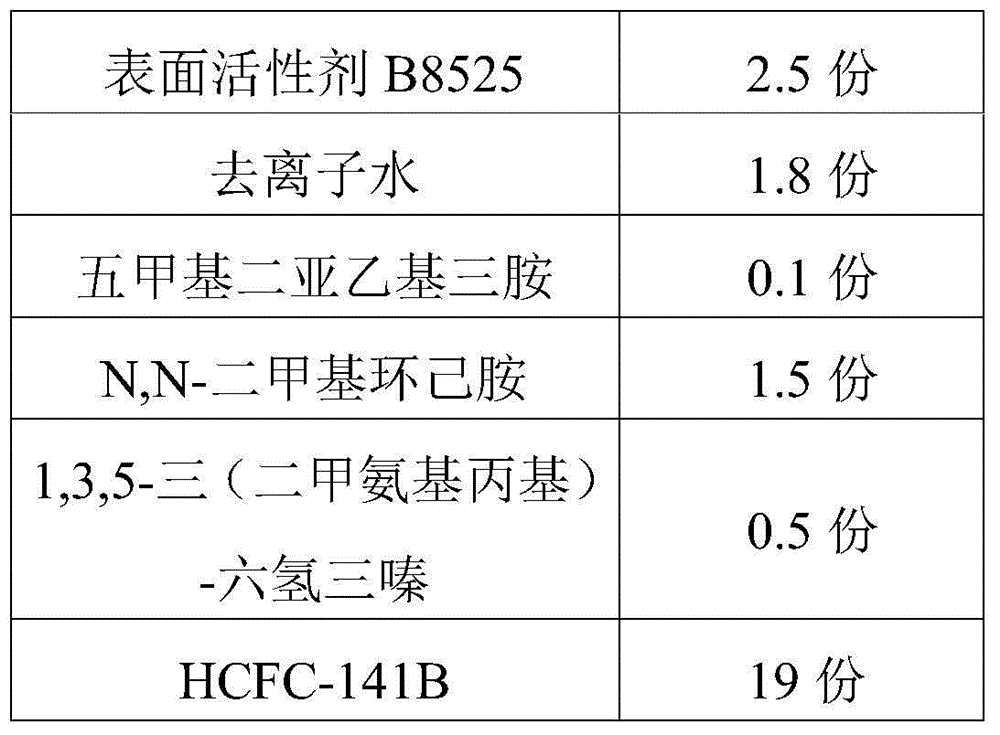

[0049] The raw material formula of combined polyether is shown in the following table:

[0050]

[0051]

[0052] Pour the raw materials mentioned in the above table into the container according to the proportion, and use an electric mixer to mix them evenly to make component A; then pour component A and isocyanate PM200 into the container according to the weight ratio of 1:1, and then use an electric mixer to Stir with the agitator for 8 seconds (the speed is 2500r / min), pour the evenly mixed liquid into the prepared polyethylene shell, and when the raw material grows to the injection port, seal the injection port, and keep it at a constant temperature of 35°C The polyurethane-polyethylene composite lifebuoy of the present invention can be obtained by aging for 2 hours under conditions.

Embodiment 2

[0054] The raw material formula of combined polyether is shown in the following table:

[0055] Polyether polyol SA460

[0056] Pour the raw materials mentioned in the above table into the container according to the specified ratio, and mix them evenly with an electric mixer to make component A; then pour component A and isocyanate PM200 into the container according to the weight ratio of 1:1, and then use Stir with an electric stirrer for 8 seconds (rotation speed is 3000r / min), pour the evenly mixed liquid into the prepared polyethylene casing, and when the raw material grows to the injection port, seal the injection port, at a constant temperature of 30 After curing for 2 hours under the condition of ℃, the polyurethane polyethylene composite lifebuoy of the present invention can be obtained.

Embodiment 3

[0058] The raw material formula of combined polyether is shown in the following table:

[0059] Polyether polyol SA460

[0060] Pour the raw materials mentioned in the above table into the container according to the specified ratio, and mix them evenly with an electric mixer to make component A; then pour component A and isocyanate PM200 into the container according to the weight ratio of 1:1, and then use Stir with an electric stirrer for 8 seconds (rotating speed is 3500r / min), pour the evenly mixed liquid into the prepared polyethylene casing, and when the raw material grows to the injection port, seal the injection port, and put it at a constant temperature of 30 After curing for 2 hours under the condition of ℃, the polyurethane polyethylene composite lifebuoy of the present invention can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com