A preparing method of low-melting point polyester used for manufacturing terylene sewing threads

A low-melting polyester and sewing thread technology, applied in the direction of adhesives, etc., can solve the problems of unsuitable polyester foreign sewing thread, uneven color of sewing thread, poor solubility, etc., and achieves good industrial application prospects, low intrinsic viscosity, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

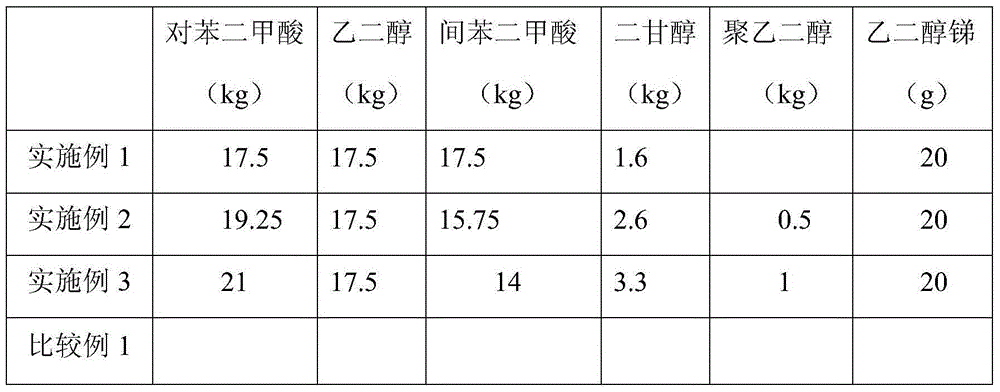

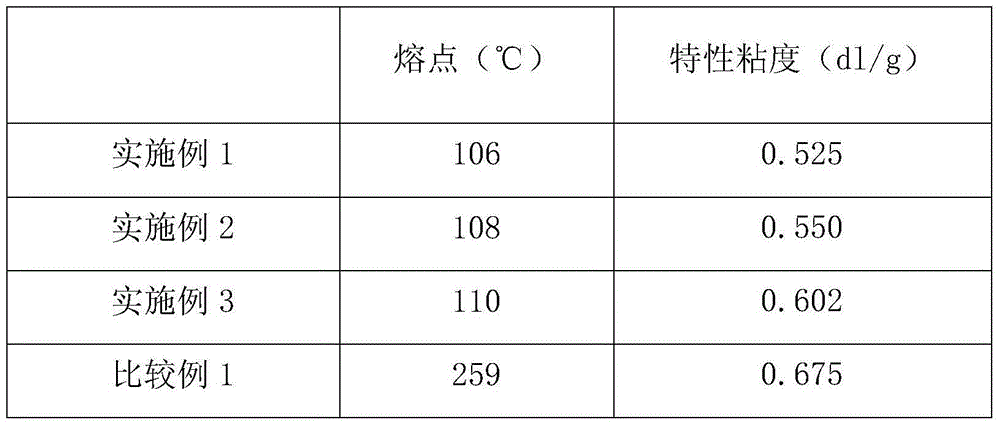

Embodiment 1~3

[0026] 1) Using terephthalic acid, ethylene glycol, isophthalic acid, and straight-chain monomers with dihydroxyl reactive functional groups other than ethylene glycol as reaction materials, carry out esterification reaction at a temperature of 240-270°C, The esterification pressure is 20-50kPa, the molar ratio of raw materials is (terephthalic acid + simple dicarboxylic acid): (ethylene glycol + linear monomer with dihydroxy reactive functional groups) = 1: 1.1-1.8, and the reaction to ester The conversion rate is not less than 92%, and the generated water is removed during the reaction process;

[0027] 2) The esterification product intermediate is further esterified and precondensed in the presence of a polycondensation catalyst, under a negative pressure of 2-10kpa, and a reaction temperature of 260-285°C to obtain a polyester oligomer with a certain degree of polymerization. The reaction time is 1.5-2.5 hours; then under the vacuum condition of negative pressure 0.1-2KPa,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com