Propene polymer composition and product prepared from same

A technology of propylene polymer and composition, applied in the field of propylene polymer composition, can solve the problems of low density incompatibility, low shrinkage rate, etc., achieve the effect of low shrinkage rate and dimensional stability, and expand the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

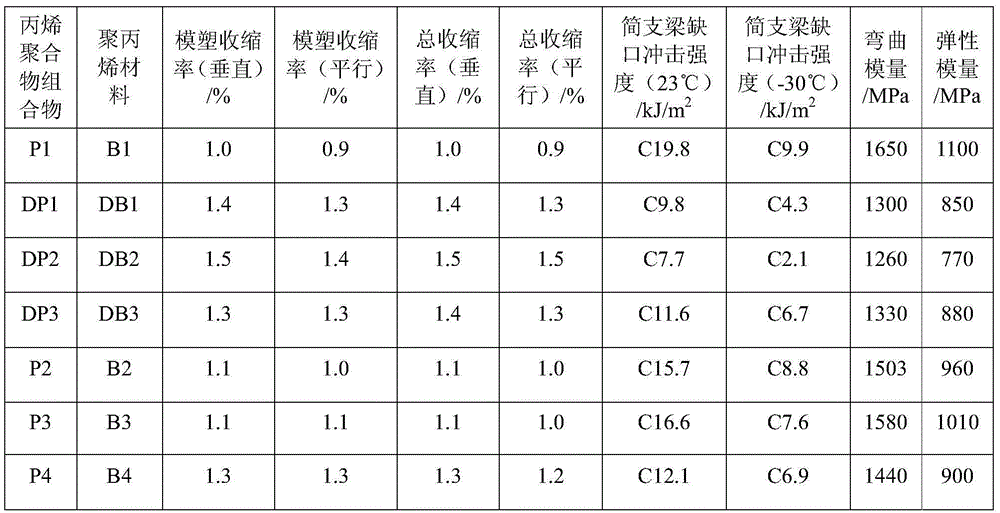

Examples

Embodiment 1

[0039] 70 parts by weight of homopolypropylene, 15 parts by weight of ethylene-butene copolymer, 15 parts by weight of propylene-ethylene-butene terpolymer, 0.01 parts by weight of HPN-68L and HPN20E (HPN-68L and The mass ratio of HPN20E is 1:1), 0.1 weight part of antioxidant 1010 and 0.2 weight part of antioxidant 168 are mixed uniformly in a high mixer, and the mixed material is sent into a twin-screw extruder, adjusted The rotation speed of the screw is 200 rpm, and the temperature of each section is controlled at 180°C, 210°C, 220°C, 200°C and 180°C respectively; the vacuum degree of each section is kept at 0.1MPa; After melting, shearing, dispersing, compressing, degassing and plasticizing in the screw and cylinder, extruding through a die and pelletizing, the propylene polymer composition P1 is obtained.

Embodiment 2

[0047] 64 parts by weight of homopolypropylene, 20 parts by weight of ethylene-butene copolymer, 16 parts by weight of propylene-ethylene-butene terpolymer, 0.01 parts by weight of HPN-68L and HPN20E (HPN-68L and The mass ratio of HPN20E is 1:1), 0.1 weight part of antioxidant 1010 and 0.2 weight part of antioxidant 168 are mixed uniformly in a high mixer, and the mixed material is sent into a twin-screw extruder, adjusted The rotation speed of the screw is 200 rpm, and the temperature of each section is controlled at 180°C, 210°C, 220°C, 200°C and 180°C respectively; the vacuum degree of each section is kept at 0.1MPa; After melting, shearing, dispersing, compressing, degassing and plasticizing in the screw and barrel, extruding through a die and pelletizing, the propylene polymer composition P2 is obtained.

Embodiment 3

[0049] 75 parts by weight of homopolypropylene, 10 parts by weight of ethylene-butene copolymer, 15 parts by weight of propylene-ethylene-butene terpolymer, 0.01 parts by weight of HPN-68L and HPN20E (HPN-68L and The mass ratio of HPN20E is 1:1), 0.1 weight part of antioxidant 1010 and 0.2 weight part of antioxidant 168 are mixed uniformly in a high mixer, and the mixed material is sent into a twin-screw extruder, adjusted The rotation speed of the screw is 200 rpm, and the temperature of each section is controlled at 180°C, 210°C, 220°C, 200°C and 180°C respectively; the vacuum degree of each section is kept at 0.1MPa; After melting, shearing, dispersing, compressing, degassing and plasticizing in the screw and barrel, extruding through a die and pelletizing, the propylene polymer composition P3 is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com