Preparation method of carbon nano tube-Kevlar nanofiber composite film

A technology of Kevlar fibers and carbon nanotubes, applied in the field of materials, can solve the problems of long time, complicated procedures, and reduce the mutual agglomeration of nanomaterials, and achieve the effects of low cost, fast preparation speed, and reduced poor dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

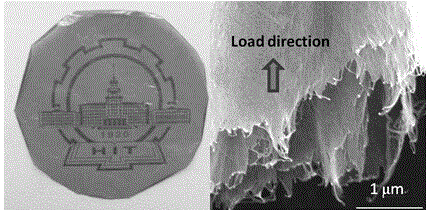

[0029] This embodiment provides a method for preparing a composite film with a carbon nanotube mass fraction of 2.5%, and the specific preparation steps are as follows:

[0030] 1. Preparation of Kevlar nanofibers: Weigh 1 g of Kevlar fibers (DuPont, K69), dry them in a vacuum drying oven for 24 hours, and take them out for use. Take 1.5 g of lithium hydroxide, put it into 500 ml of dimethyl sulfoxide with the dried Kevlar fiber and magnetically stir it for 1 week to obtain a dark red Kevlar nanofiber solution.

[0031] 2. Preparation of carbon nanotube dispersion: Weigh 20 mg of multi-walled carbon nanotubes, add 120 ml of concentrated sulfuric acid and concentrated nitric acid mixture with a volume ratio of 3:1, stir for 4 hours at 60 ° C, and then ultrasonically shake for 2 Hour. The resulting solution was diluted with deionized water, filtered through a microporous membrane, and the solid on the membrane was washed until the pH of the filtrate was 7, and the obtained blac...

Embodiment 2

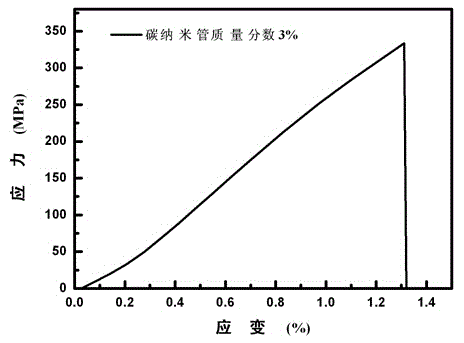

[0036] This embodiment provides a method for preparing a composite film with a carbon nanotube mass fraction of 3%, and the specific preparation steps are as follows:

[0037] 1. Preparation of Kevlar nanofibers: Weigh 1.5 g of Kevlar fibers (DuPont, K69), dry them in a vacuum oven for 24 hours, and take them out for use. Take 2g of lithium hydroxide, put the dried Kevlar fiber into 750ml of dimethyl sulfoxide and magnetically stir for 1 week to get a dark red Kevlar nanofiber solution.

[0038] 2. Preparation of carbon nanotube dispersion: Weigh 30 mg of multi-walled carbon nanotubes, add 150 ml of concentrated sulfuric acid and concentrated nitric acid mixture with a volume ratio of 3:1, stir for 4 hours at 60 ° C, and then ultrasonically shake for 2 Hour. The resulting solution was diluted with deionized water, filtered through a microporous membrane, and the solid on the membrane was washed until the pH of the filtrate was 7, and the obtained black precipitate was dried i...

Embodiment 3

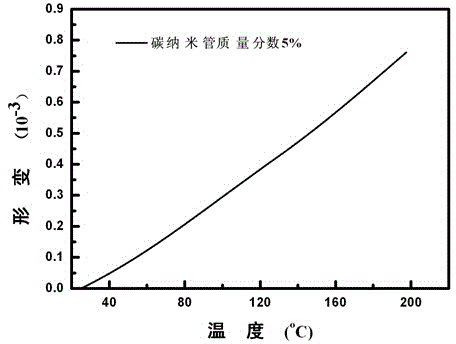

[0044] This embodiment provides a method for preparing a composite film with a carbon nanotube mass fraction of 5%, and the specific preparation steps are as follows:

[0045] 1. Preparation of Kevlar nanofibers: Weigh 2 g of Kevlar fibers (DuPont, K69), dry them in a vacuum drying oven for 12 hours, and take them out for use. Take 2 g of lithium hydroxide, put the dried Kevlar fiber into 1000 ml of dimethyl sulfoxide and magnetically stir for 1 week to obtain a dark red Kevlar nanofiber solution.

[0046] 2. Preparation of carbon nanotube dispersion: Weigh 30 mg of multi-walled carbon nanotubes, add 180 ml of concentrated sulfuric acid and concentrated nitric acid mixture with a volume ratio of 3:1, stir for 4 hours at 60 ° C, and then ultrasonically shake for 2 Hour. The resulting solution was diluted with deionized water, filtered through a microporous membrane, and the solid on the membrane was washed until the pH of the filtrate was 7, and the obtained black precipitate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com