Preparation method of alcohol-soluble acrylic rosin resin

An acrylic rosin and alcohol-soluble technology, which is applied in the field of rosin processing, can solve the problems of easy volatilization, air pollution, and high printing costs, and achieve the effects of increased competitiveness, high softening point, and good alcohol solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

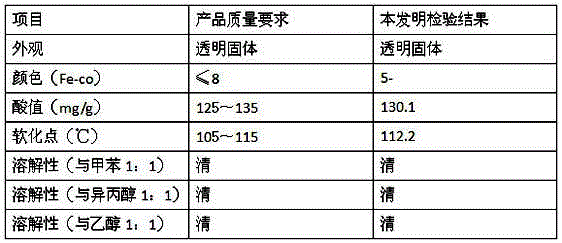

Examples

Embodiment Construction

[0016] Below in conjunction with example, the present invention is described in further detail:

[0017] A kind of preparation method of alcohol-soluble acrylic rosin resin comprises the following steps:

[0018] A. First put 210Kg of rosin into the reactor for heating, when the temperature of the rosin material reaches 150°C to 160°C, start the stirrer of the reactor, and then add 0.21Kg of 4,4`-thio Two (6-tert-butyl-3-methylphenol) reacted and continued heating;

[0019] B. When the temperature of the material in the reactor reaches 195°C to 200°C, add 15.8Kg of acrylic acid into the reactor, and seal the reactor, then react 2 at the pressure of the reactor at 0.1 MPa to 0.3 MPa Hour;

[0020] C. After the reaction described in step B is completed, the reactor is depressurized and emptied, 8.8Kg of glycerin is added, and heated to 250° C. to 255° C. for esterification for 1 hour;

[0021] D. After the reaction in step C is over, turn on the vacuum pump to evacuate the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com