Lubricating gasoline detergent dispersant

A technology for cleaning dispersants and gasoline, applied in the field of gasoline additives, can solve problems such as insignificant effects, and achieve the effects of simple production process, saving energy and cost, and reducing the generation of carbon deposits in an engine air intake system and a combustion chamber.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

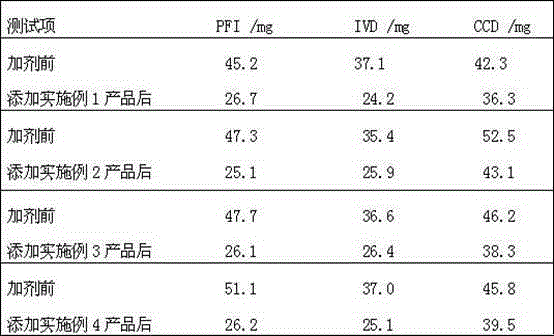

Examples

Embodiment 1

[0019] Take 9 parts of polyisobutylene amine, 6 parts of tetrahydrofurfuryl nitrate, and 5 parts of polyetheramine into a closed mixing tank, and mix well, then add 3 parts of polyisobutylene isobutyl carbamate, polyisobutadiene 0.5 parts of ethylenediamine, 8 parts of ethylene glycol dimethyl ether, stir for 10-15 minutes and mix well, then add 4 parts of 4,4'-dihexyldiphenylamine, 4-hexyl-4'-octyl 1 part of diphenylamine, stirred for 15-20 minutes to mix uniformly to obtain the lubricating gasoline detergent and dispersant of the present invention.

Embodiment 2

[0021] Take 9 parts of polyisobutylene amine, 9 parts of tetrahydrofurfuryl nitrate, and 5 parts of polyetheramine and add them into a closed mixing tank. After mixing well, add 5 parts of polyisobutylene isobutyl carbamate, polyisobutadiene 0.5 parts of ethylenediamine, 5 parts of ethylene glycol dimethyl ether, stir for 10-15 minutes and mix well, then add 4 parts of 4,4'-dihexyldiphenylamine, 4-hexyl-4'-octyl 3 parts of diphenylamine, stirred for 15-20 minutes to mix uniformly to obtain the lubricating gasoline detergent and dispersant of the present invention.

Embodiment 3

[0023] Take 12 parts of polyisobutylene amine, 6 parts of tetrahydrofurfuryl nitrate, and 3 parts of polyether amine and add them into a closed mixing tank. After mixing well, add 5 parts of polyisobutylene carbamate, polyisobutadiene 0.5 parts of ethylenediamine, 5 parts of ethylene glycol dimethyl ether, stir for 10-15 minutes and mix well, then add 4 parts of 4,4'-dihexyldiphenylamine, 4-hexyl-4'-octyl 3 parts of diphenylamine, stirred for 15-20 minutes to mix uniformly to obtain the lubricating gasoline detergent and dispersant of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com