Production process of strong aromatic white wine

A strong-flavor liquor and a production process technology, applied in the field of winemaking, can solve the problems of insufficient softness, lack of fullness of the wine, and difficulty in fully reflecting the compound aroma, and achieve the effect of the best taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be described in detail below.

[0026] A production process of Luzhou-flavor liquor, comprising the following steps:

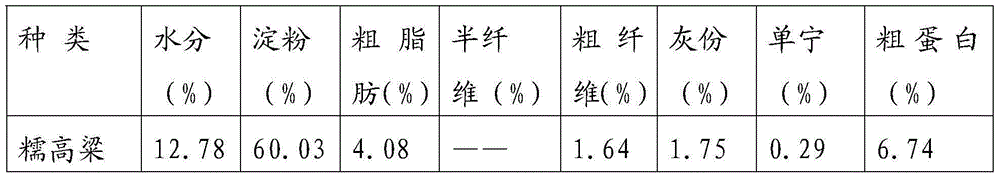

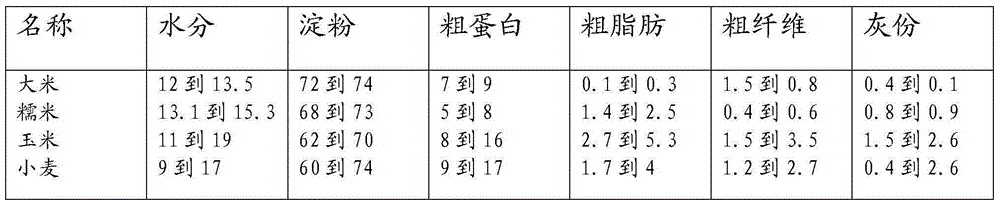

[0027] Step 1. Select sorghum, rice, glutinous rice, corn, buckwheat and wheat according to the properties of each raw material and the degree of gelatinization of starch. The sorghum is waxy sorghum with full grains, no impurities, and no mildew. %—3%, the percentage by weight in the grain is 0.2%—0.3%, and the germ of corn is removed;

[0028] Step 2, crushing various screened raw materials to make brewed grain, wherein the weight percentages of each raw material are: 30%-45% of sorghum, 18%-25% of rice, 10%-22% of glutinous rice, 8%-12% of corn %, wheat 10%-18%, buckwheat 5%-8%, wherein the specific weight percentage of each raw material is: sorghum 36%, rice 20%, glutinous rice 15%, corn 10%, wheat 13%, buckwheat 6%;

[0029] Step 3: Mix the fermented grain soaked for 20 hours to 24 hours with the steamed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com