Petroleum drilling top drive safety valve protecting joint

A technology for oil drilling and safety valves, which is applied to drilling equipment, drill pipes, drill pipes, etc. It can solve the problems of increasing safety hazards in drilling operations, inability to place filter cartridges, and impacts on drilling operations, so as to reduce drilling risks, operation and use. Convenience and long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

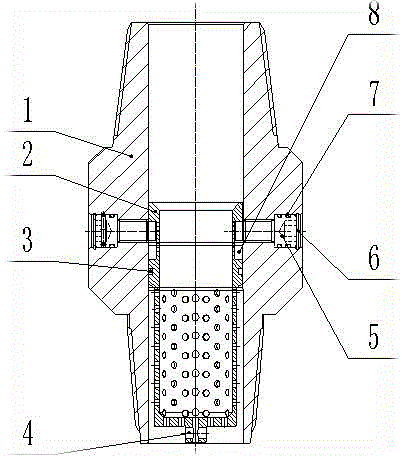

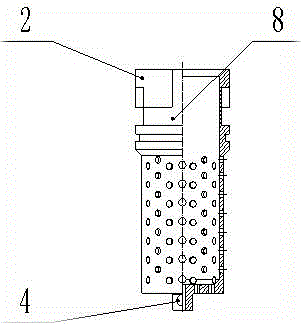

[0018] Now combined with the accompanying drawings of the manual figure 1 , figure 2 The present invention is further described.

[0019] The protection joint of the top drive safety valve for oil drilling includes the main body of the protection joint 1, the filter cartridge 2, the seal 1 3, the disassembly hole 4, the screw 5, the retaining ring 6, the seal 2 7, the reverse L-shaped groove 8, and the protection joint The main body 1 is in the shape of a round tube, with threads processed at both ends. The inner hole has a section with a small inner diameter in the middle part, and there are two symmetrical threaded holes radially upward at this section with a small inner diameter. The outside of the threaded hole is a counterbore , The outer part of the counterbore is processed with an annular groove. The filter cartridge 2 is a cylinder with one end closed. The upper part has a larger diameter. Two symmetrical reverse L-shaped grooves 8 are processed on the upper part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com