Well body structure and method for underground upgrading and exploitation of heavy oil and ultra-heavy oil reservoirs

A technology for super-heavy oil and well structure, which is applied in chemical instruments and methods, production fluids, and earth-moving drilling, etc., can solve the problems of steam channeling, limited effect of heavy oil modification, and difficulty in uniform distribution, etc. The effect of ensuring liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

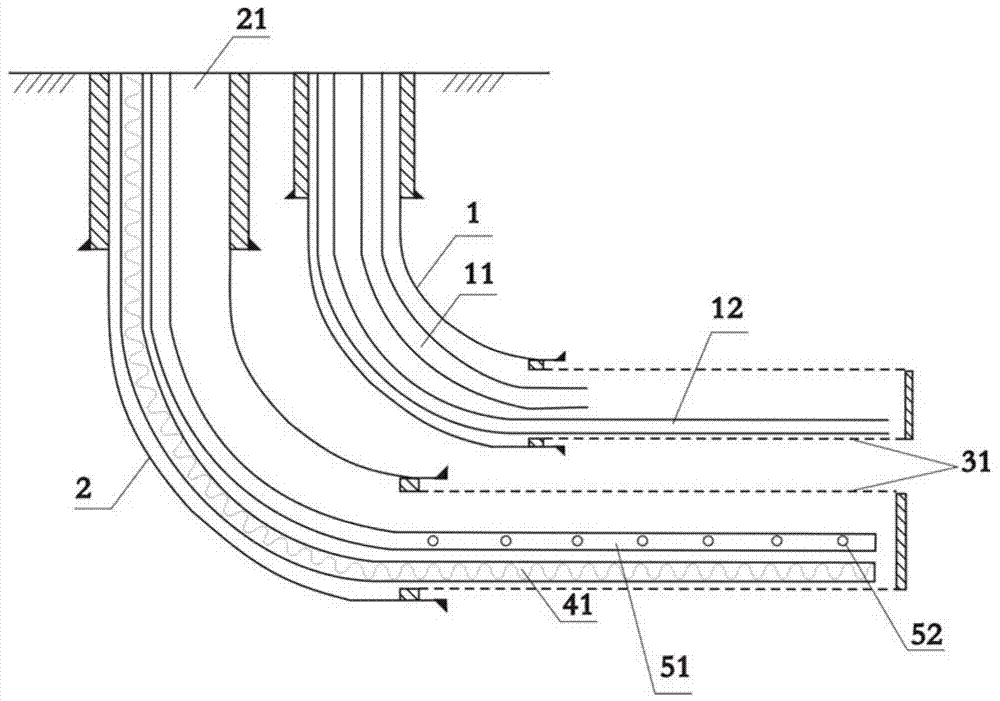

[0060] This embodiment provides a well body structure for underground upgrading and exploitation of heavy oil and super heavy oil reservoirs. The structure of the well body structure is as follows figure 1 As shown, the details are as follows:

[0061] Injection-production well pattern (horizontal well-horizontal well SAGD well pattern) vertical overlap of injection well 1 and production well 2, the horizontal section is parallel to each other, the vertical distance between the horizontal section of injection well and the horizontal section of production well is 5 meters, the horizontal section The length is 500 meters; the injection well 1 is completed through a screen 31 with a nozzle diameter of 9 inches; the production well 2 is completed through a screen 31 with a nozzle diameter of 9 inches;

[0062] The injection well 1 of the injection-production well pattern is provided with parallel double oil pipes stretching into the heel and toe of the horizontal section of the in...

Embodiment 2

[0077] This embodiment provides a well body structure for underground upgrading and exploitation of heavy oil and super heavy oil reservoirs. The structure of the well body structure is as follows:

[0078] The injection-production well pattern is a horizontal well-horizontal well SAGD well pattern, the vertical overlap of the injection well and the production well, the horizontal sections are parallel to each other, the vertical distance of the vertical horizontal section is 5 meters, and the length of the horizontal section is 600 meters; the diameter of the injection well through the nozzle Completion wells with 11-inch screens; production wells completed with 11-inch nozzle diameter screens;

[0079] The injection wells of the injection-production well pattern are provided with parallel double oil pipes extending into the heel and toe of the horizontal section of the injection well. into the heel), the nozzle diameter of the long tubing is 4.5 inches, and the nozzle diamet...

Embodiment 3

[0094] This embodiment provides a well body structure for underground upgrading and exploitation of heavy oil and super heavy oil reservoirs. The structure of the well body structure is as follows:

[0095] The injection-production well pattern is a horizontal well-horizontal well SAGD well pattern, the vertical overlap of the injection well and the production well, the horizontal sections are parallel to each other, the vertical distance of the vertical horizontal section is 5 meters, and the length of the horizontal section is 700 meters; the diameter of the injection well through the nozzle Completion wells with 11-inch screens; production wells completed with 11-inch nozzle diameter screens;

[0096] The injection wells of the injection-production well pattern are provided with parallel double oil pipes extending into the heel and toe of the horizontal section of the injection well. into the heel), the nozzle diameter of the long tubing is 4.5 inches, and the nozzle diamet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com