An underground hydrogenation catalytic upgrading recovery method for heavy oil and super heavy oil reservoirs

A technology for super-heavy oil and recovery methods, which is applied in chemical instruments and methods, production fluids, and earth-moving drilling, etc., can solve the problems of limited modification effect, rebound of crude oil viscosity, and oil reservoir damage, and achieve accelerated hydrogenation reformation. quality rate, slow down the rate of failure, increase the effect of activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This example provides an underground hydrogenation catalytic upgrading recovery method for heavy oil and super heavy oil reservoirs. The selected heavy oil reservoir has a burial depth of 2200 meters and a crude oil viscosity of 200000 mPa·s at 50 °C on the ground. The heavy oil reservoir developed by water flooding, the method includes the following specific steps:

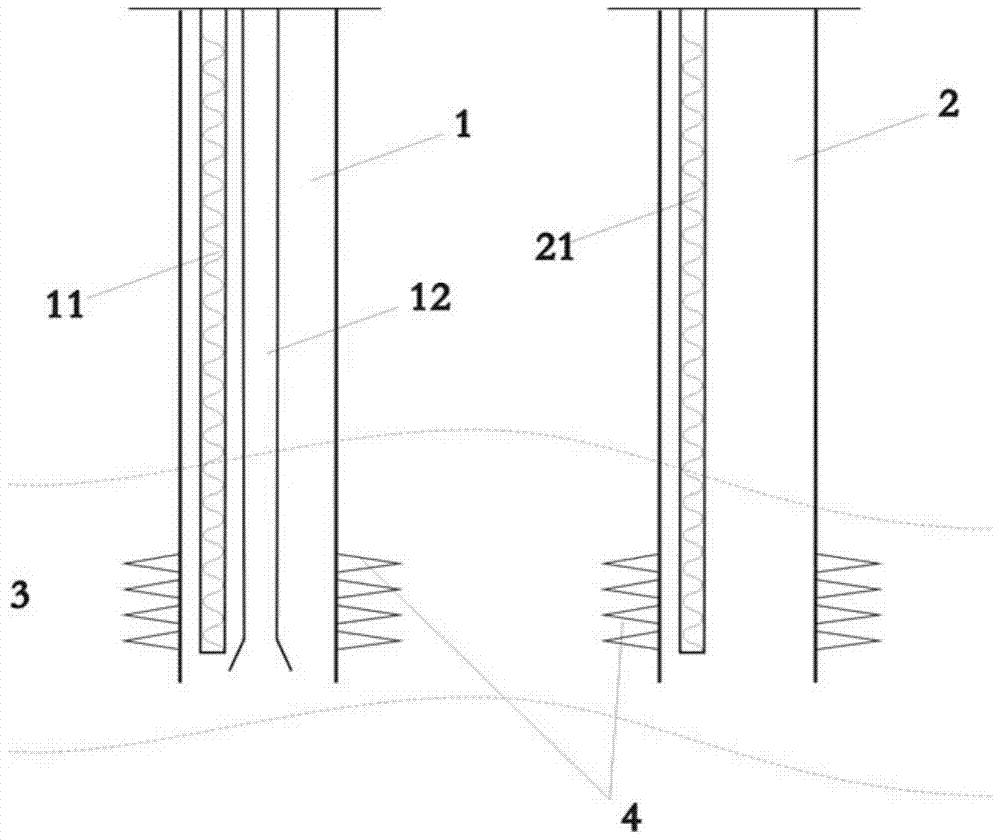

[0051] (1) A vertical five-point injection-production well pattern is deployed in the oil layer 3, and a perforation section 4 is set in the part where the injection well 2 and the production well 1 are located in the oil layer 3, specifically as figure 1 shown;

[0052] (2) The high-energy molten salt heating pipe 21 is lowered into the injection well 2, and the catalyst injection pipe 12 (with a bell mouth at the lower end) and the high-energy molten salt heating pipe 11 are lowered into the production well 1; the molten salt in the high-energy molten salt heating pipe used is is potassium nitrate;

[...

Embodiment 2

[0059] This example provides an underground hydrogenation catalytic upgrading recovery method for heavy oil and ultra-heavy oil reservoirs. The selected heavy oil reservoir has a burial depth of 1,200 meters and a crude oil viscosity of 100,000 mPa·s at a ground temperature of 50°C. heavy oil reservoirs, including the following specific steps:

[0060] (1) Deploy a vertical anti-seven-point injection-production well pattern in the oil layer, and set a perforation section in the part where the injection well and the production well are in the oil layer;

[0061] (2) A high-energy molten salt heating pipe is lowered into the injection well, and a catalyst injection pipe (bell mouth is opened at the lower end) and a high-energy molten salt heating pipe are lowered into the production well; the molten salt in the high-energy molten salt heating pipe used is potassium nitrate;

[0062] (3) The injection well continuously heats the wellbore through the molten salt heating tube to a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com