Multi-actuator heavy-duty digital hydraulic circuit based on high-pressure common rail cabin

A high-pressure common rail, multi-actuator technology, used in servo meter circuits, machines/engines, fluid pressure actuation devices, etc., can solve problems such as slow response time, reduce pressure fluctuations, and reduce valve frequency response. requirements, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

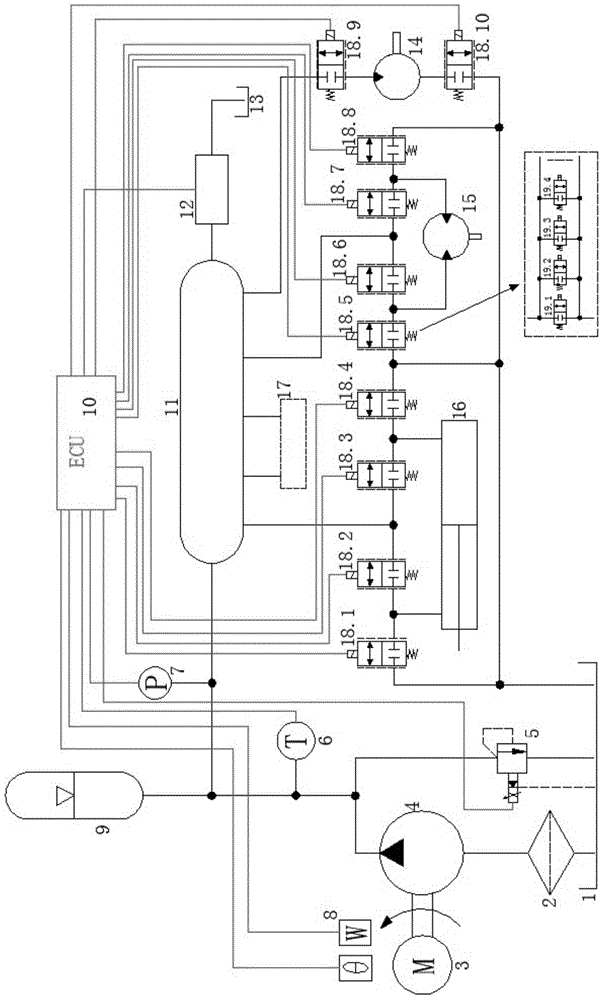

[0027] Such as figure 1 The shown multi-actuator heavy-duty digital hydraulic circuit based on the high-pressure common rail cabin includes an oil supply system, a high-speed switching valve group, an electronic control unit 10 and actuators. By integrating the high-pressure common rail method and digital hydraulic circuit technology: the high-pressure oil accumulated in the high-pressure chamber 11 is delivered to each actuator through the high-speed switching valve group, and each actuator is also discharged through the high-speed switching valve group. Return to the oil tank; the entire hydraulic system is controlled by an electronic control unit 10 (ECU). By inputting the expected operating rules of the load and monitoring system operating parameters, the number of small flow high-speed switching valves in each high-speed switching valve gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com