Hydraulic system of wheeled tractor

A wheeled tractor and hydraulic system technology, applied in the field of tractors, can solve problems such as hydraulic system stuck valve, hydraulic system functional requirements, faults, etc., and achieve the effects of reducing the probability of stuck valve, rigorous structure, and reducing sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

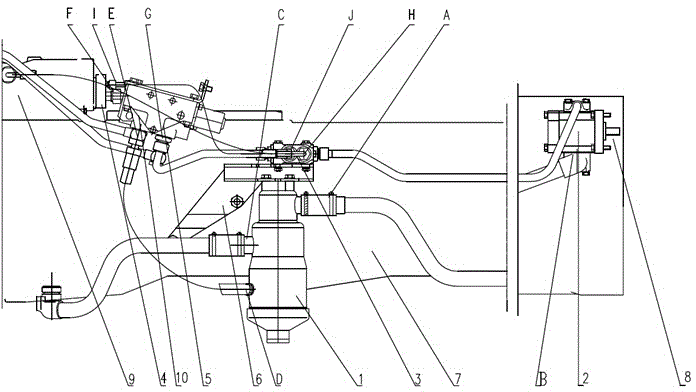

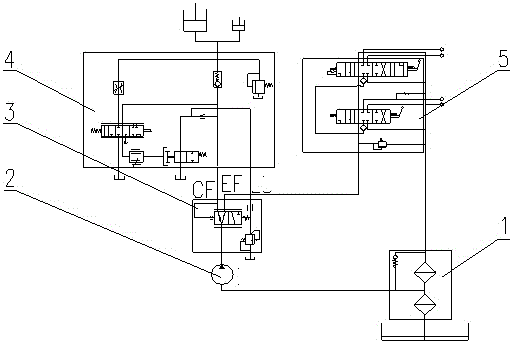

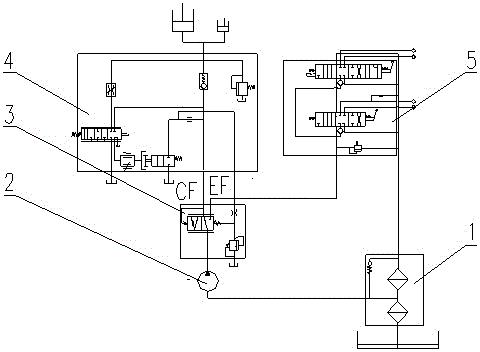

[0011] The present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 1~4 As shown, a hydraulic system for a wheeled tractor mainly includes a double-barrel oil filter 1, a gear pump 2, a priority valve 3, a distributor 4, and a hydraulic output valve plate 5; it is characterized in that: the double-barrel oil filter 1 is fixed on the side of the transmission case 7 through the fixing bracket 6 and bolts; the gear pump 2 is fixed on the side of the gear chamber 8 of the engine positive chamber through bolts; the priority valve 3 is fixed on the fixing bracket 6 through bolts; the distributor 4 is fixed on the On the lifter housing 9; the hydraulic output valve plate 5 is fixed on the multi-way valve bracket 10 by bolts. The duplex oil filter 1, the gear pump 2, the priority valve 3, the distributor 4, and the hydraulic output valve plate 5 are connected through pipelines.

[0012] The upper outlet A of the duplex oil filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com