Throttling valve

A throttle valve and valve head technology, which is applied to valve details, safety valves, balance valves, etc., can solve the problems of turbulent flow at the water inlet end surface and large water flow resistance, and achieve the effect of reducing turbulence, reducing resistance, and concentrating water outlet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

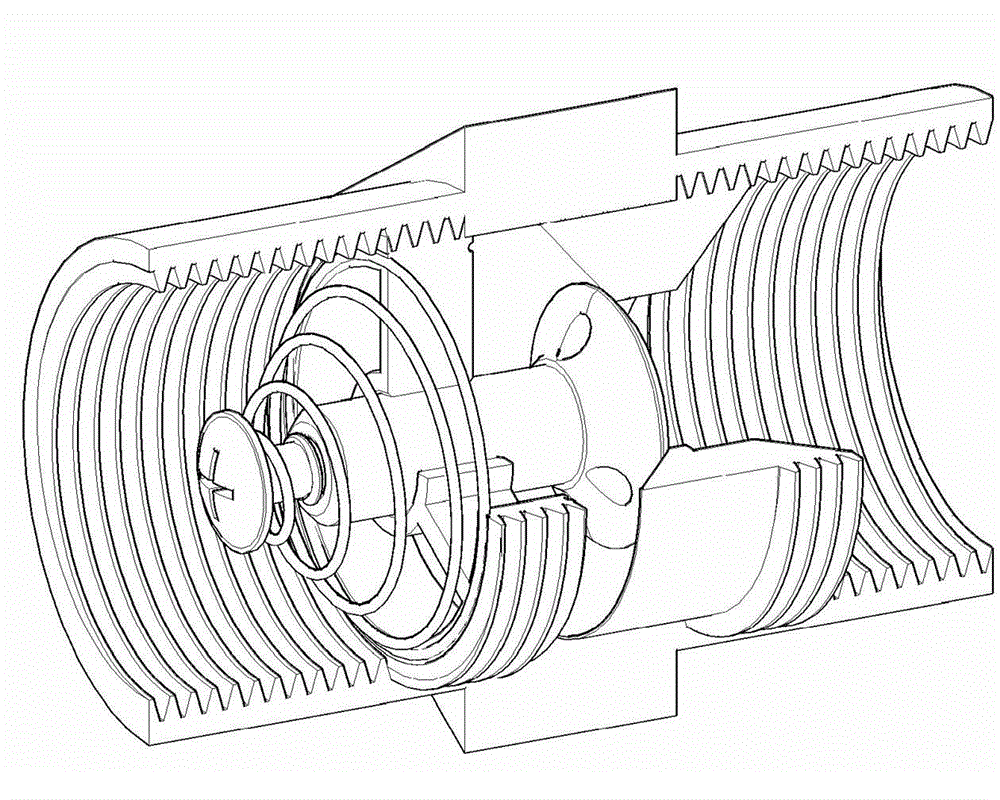

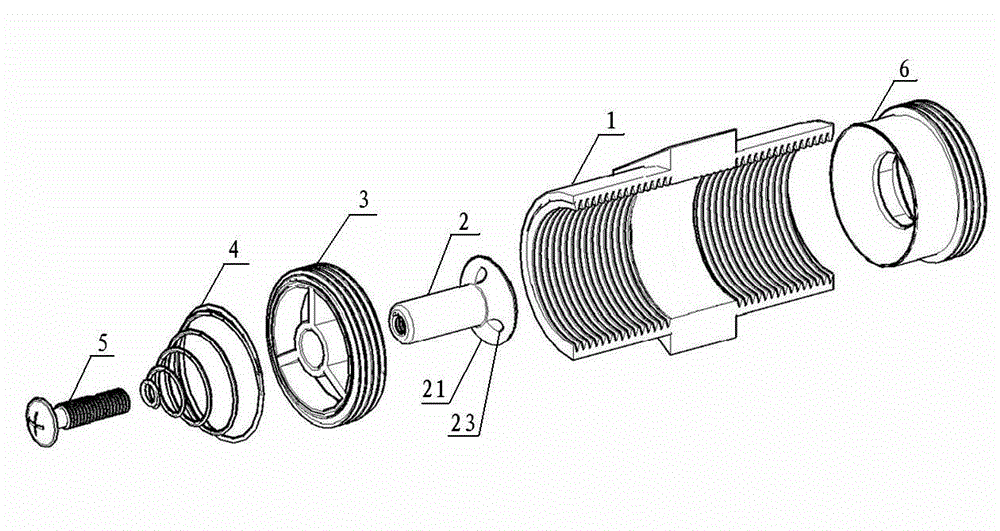

[0018] Such as figure 1 , one A throttle valve is installed in a water pipe joint for use. The water pipe joint is mainly composed of a body 1, a throttle valve 2, a bracket 3, a spring 4, a screw 5 and a valve seat 6.

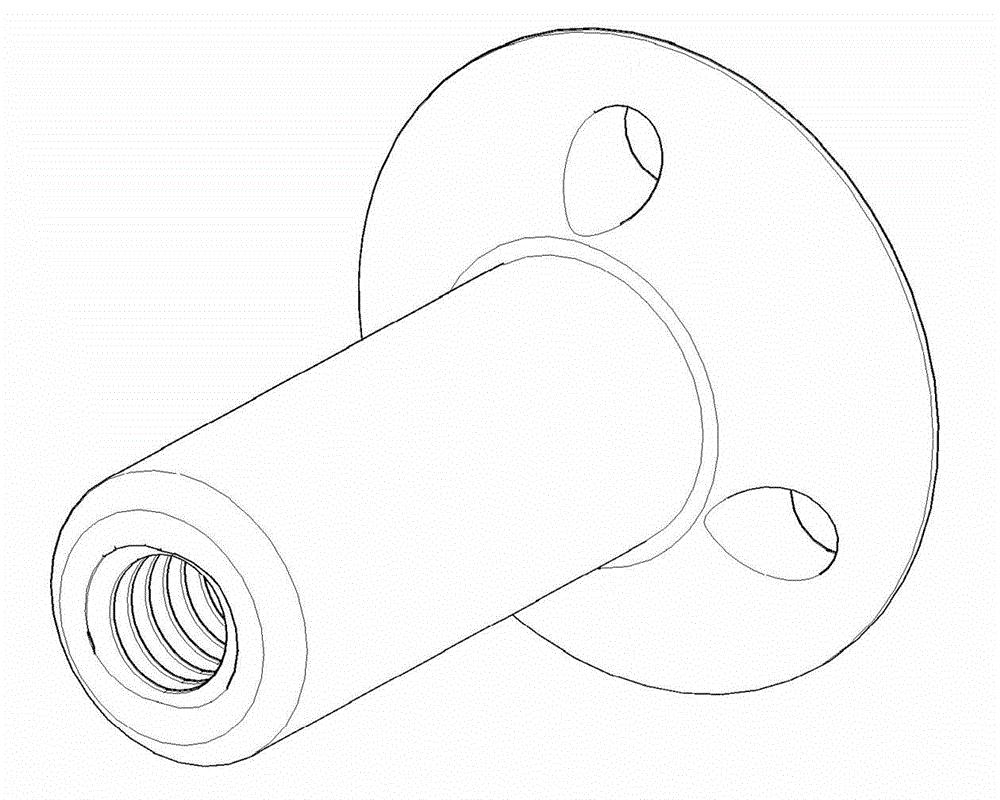

[0019] Throttle valve comprises valve head 21 and valve stem 22 again, is provided with more than two water passage holes 23 that run through valve head on valve head, is provided with the threaded hole coaxial with valve stem on valve stem; Through the fixing hole in the middle of the bracket and then through the spring, screw the screw 5 into the screw hole on the valve stem, fix the spring between the nut and the bracket 3, and then slide the bracket from the body in the direction that the screw cap faces the water inlet. The water inlet end is plugged into the body and fixed.

[0020] The valve seat is installed downstream of the throttle valve in the body, and a through hole is provided on the valve seat, and the wall surface of the through hole facin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com