supercritical co 2 Flowmeter calibration device and calibration method thereof

A calibration device and flowmeter technology, applied in measuring devices, test/calibration devices, liquid/fluid solid measurement, etc., can solve problems such as unreachable temperature conditions, unachievable, no temperature adjustment mechanism, etc., to achieve stable pressure fluctuations Problems, the effect of ensuring measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The working state of the flowmeter used for downhole measurement of layered CO2 injection gas wells is a high temperature and high pressure environment. The temperature is generally between 50 and 150 ° C, and the pressure is generally above 10 MPa. This range is the supercritical state of CO2. Commercially purchased CO2 is in a liquid tank, the temperature is about -20°C to -30°C, and the pressure inside the tank is generally about 2MPa. According to this condition, in order to change the liquid CO2 into a supercritical state, the experimental device needs to increase the temperature and pressure of the liquid CO2.

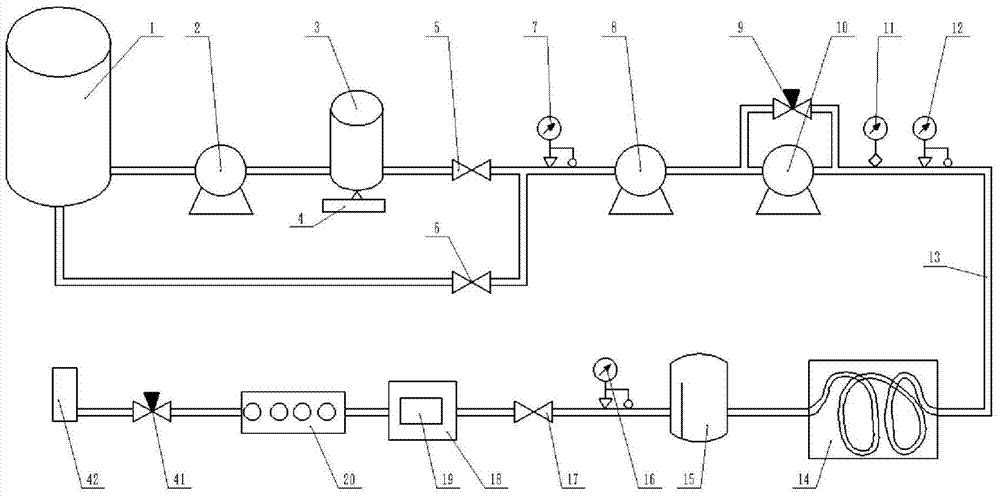

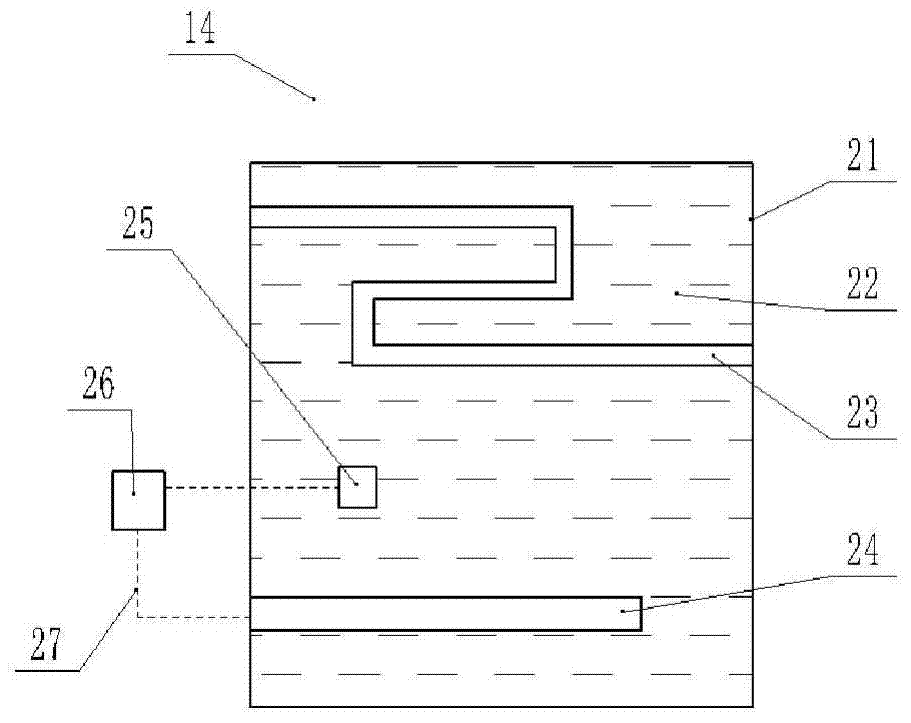

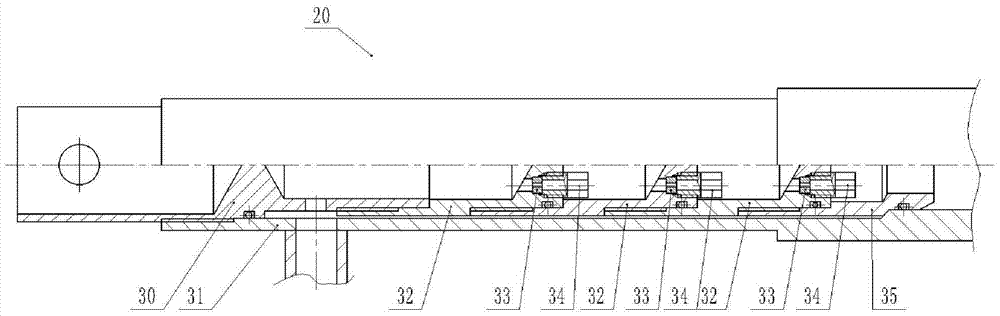

[0028] see figure 1 Supercritical CO 2 Schematic diagram of the flow meter calibration device, the metering tank 3 is installed on the weighing device 4, and the gas storage tank 1, the pouring pump 2, the metering tank 3, the valve 1, the liquid feeding pump 8, and the booster pump 10 are connected in sequence with the pipeline 13 , heat exchanger 14, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com