Measuring method and measuring device for membrane stress

A thin film stress and thin film technology, which is applied in the field of thin film stress measurement methods and measurement devices, can solve problems such as measurement result errors, achieve the effects of reducing measurement errors, improving accuracy, and having a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

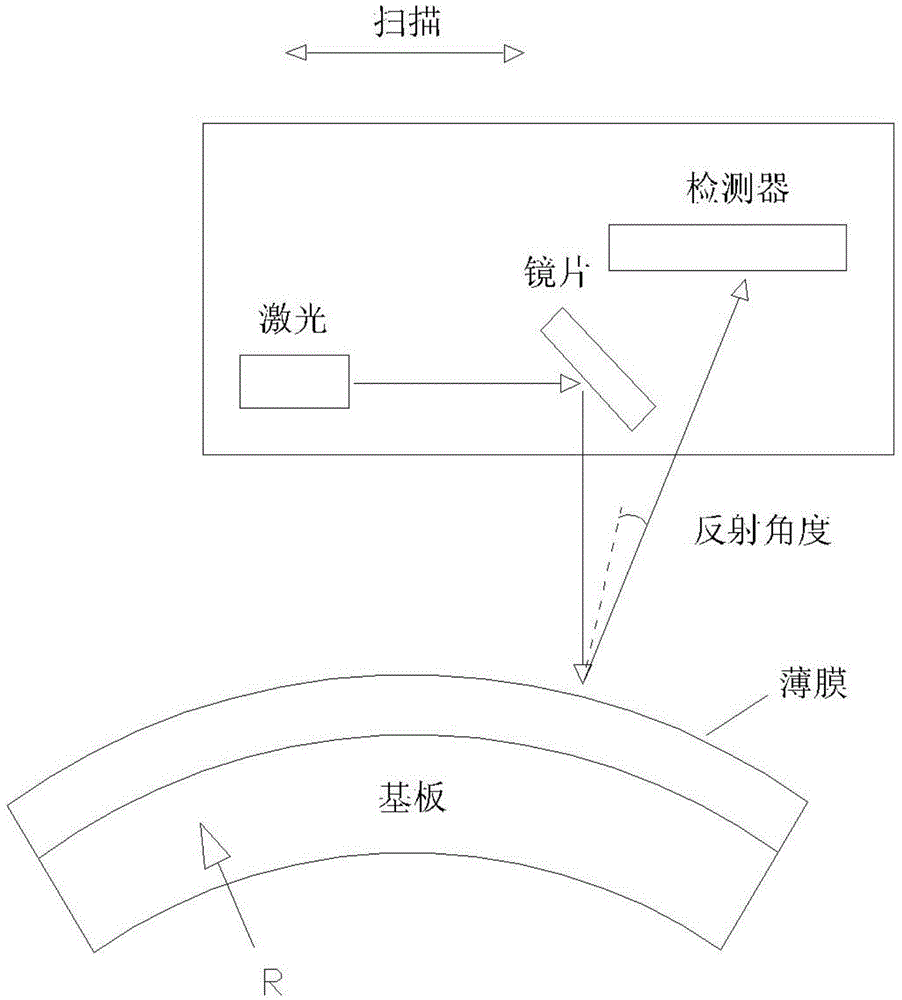

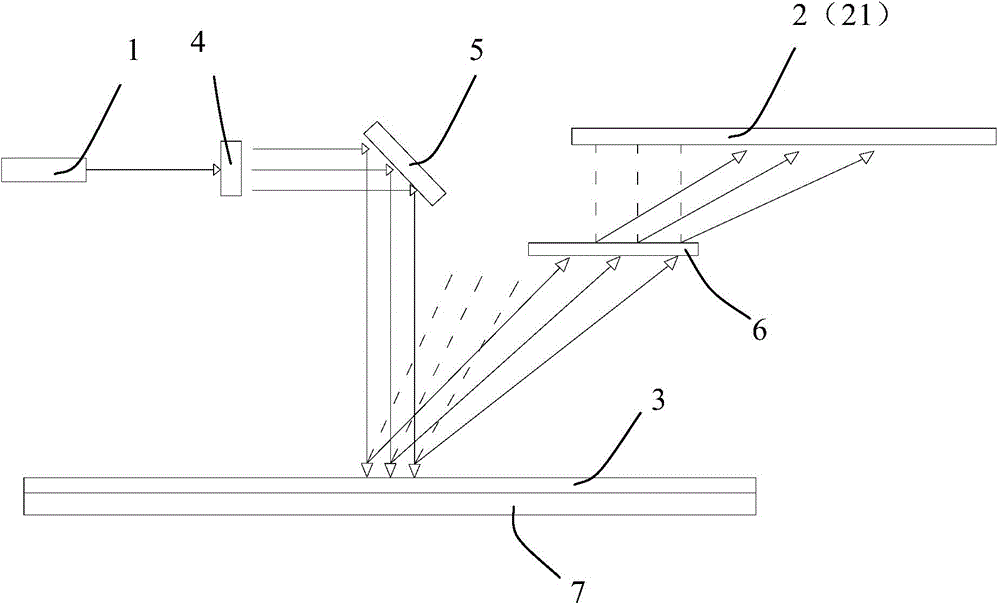

[0038] see figure 2 Shown is a schematic diagram of the structure of the thin film stress measurement device of the present invention.

[0039] In one embodiment, as figure 2 As shown, the film stress measuring device of the present invention includes a laser emitter 1 and a detector 2 .

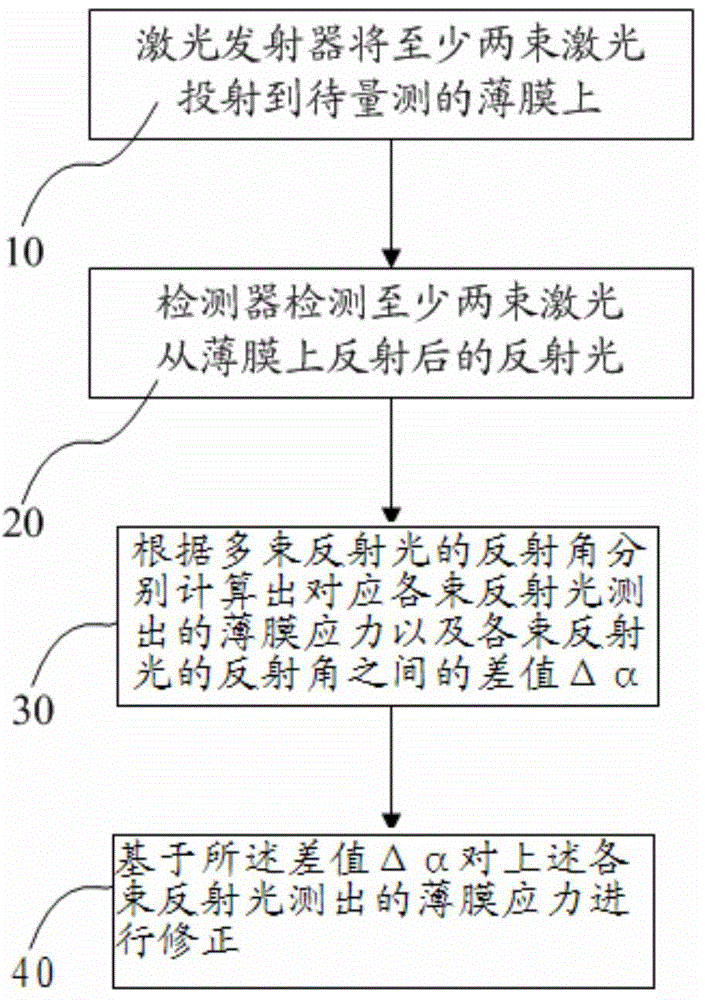

[0040] Utilize the device of this embodiment to carry out the film stress measurement method, such as image 3 shown, including the following steps:

[0041] Step (10) The laser transmitter 1 projects at least two laser beams onto the film 3 to be measured;

[0042] Step (20) the detector 2 detects the reflected light of the at least two laser beams reflected from the film 3;

[0043] Step (30) Calculate the film stress measured corresponding to each beam of reflected light and the difference Δα between the reflection angles of each beam of reflected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com