Device used for producing schist similar materials

A technology of similar materials and troughs, applied in the field of geotechnical engineering, can solve problems such as the inability to simulate the interval distribution of sheet minerals and granular minerals, difficulty in making interlayered similar materials, and large differences in connection methods, etc., to achieve structural Simple, easy to assemble, and the effect of uniform feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

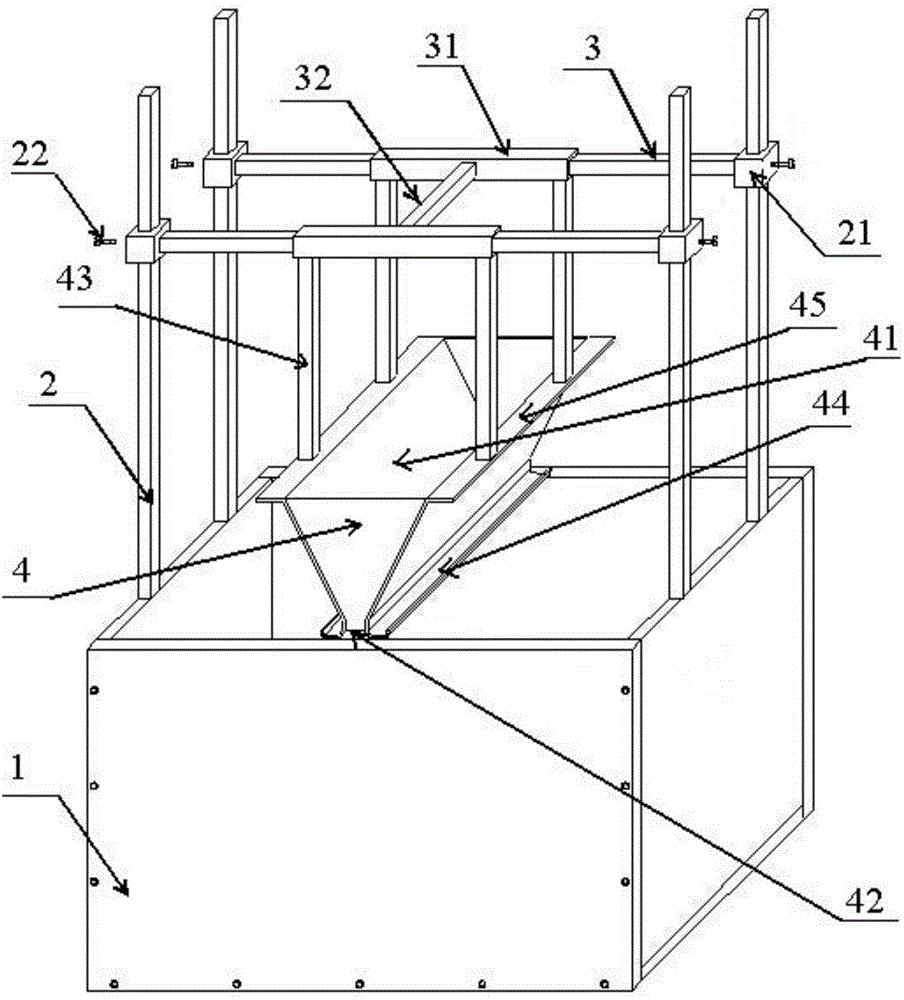

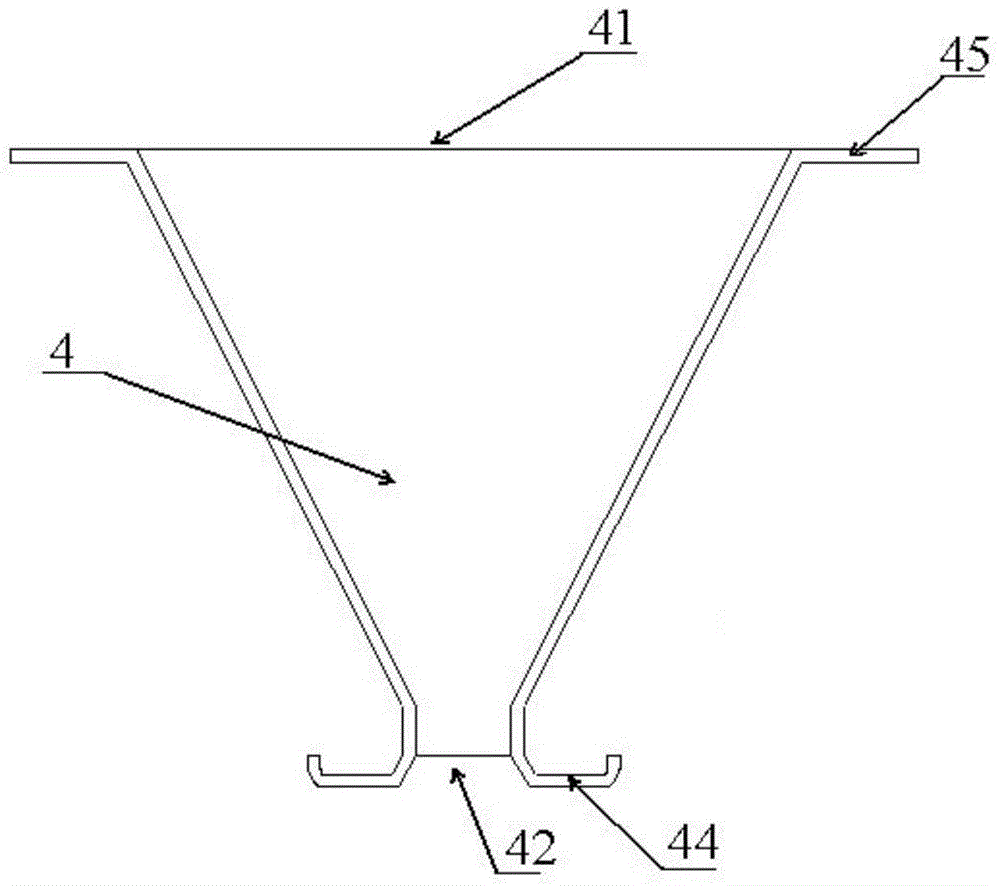

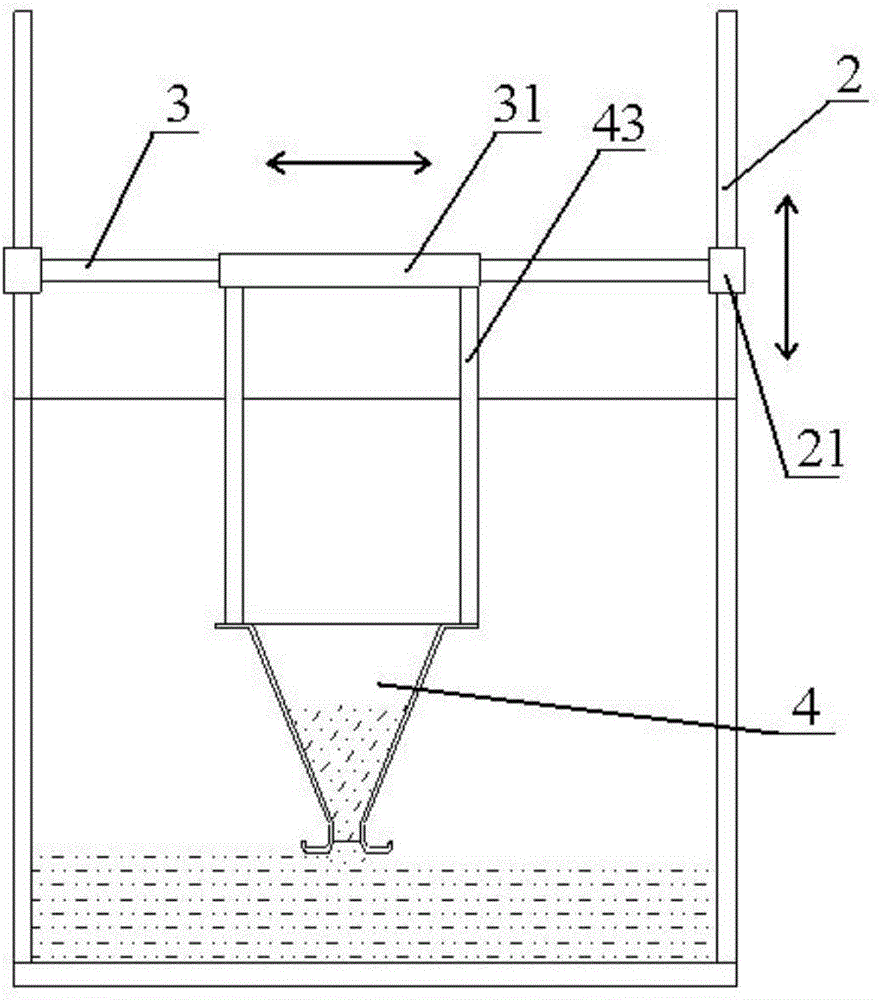

[0029] Such as figure 1 , figure 2 , image 3 The shown device for making schist-like materials includes a mold 1 without an upper cover. The mold 1 is a hollow cuboid inside. The mold 1 is provided with a feeding device, and the feeding device includes 4 vertical slide rails 2 , 2 horizontal slide rails 3 and a feeding trough 4, four vertical slide rails 2 are symmetrically arranged on the two short side walls of the mold 1, two vertical slide rails 2 are arranged on each short side wall, different short side walls A pair of vertical slide rails 2 is provided with a horizontal slide rail 3, the two ends of the horizontal slide rails 3 are provided with vertical sliders 21 that can slide along the vertical slide rails 2, and each horizontal slide rail 3 is provided with a Slide the horizontal slide block 31 along the horizontal slide rail 3, and there are four symmetrical and vertical connecting rods 43 near the two ends of the feeding trough 4, and the two connecting rods ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com