Device and method for testing rebound rate of O-shaped sealing ring

A testing device and rebound rate technology, which is applied in the direction of testing material hardness, etc., can solve the problems of sealing ring and sealing surface contact pressure seal failure, rubber ring rebound speed can not respond to the deformation of shell structural parts in time, and achieve stable performance , Reliable structure and simple principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

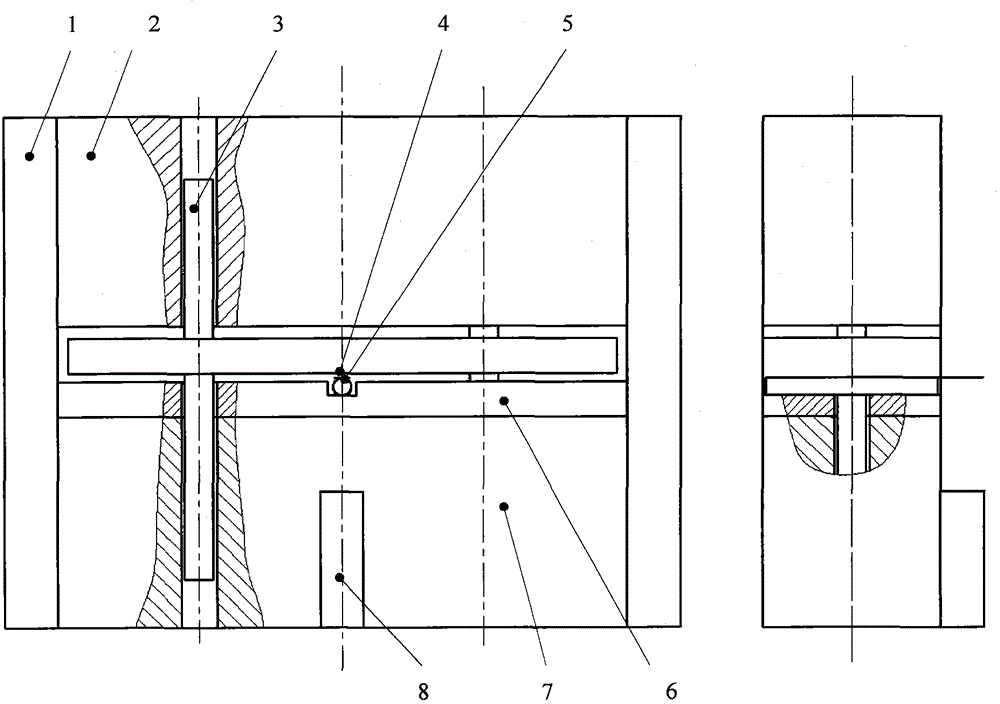

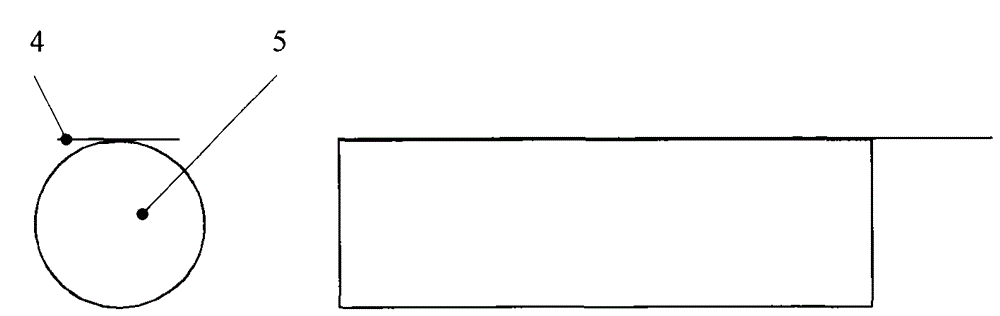

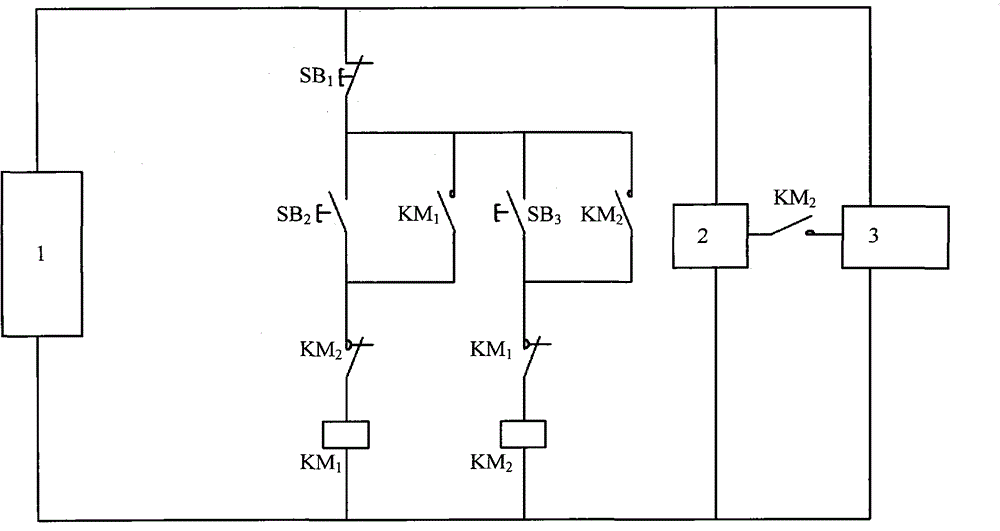

[0019] Such as figure 1 As shown, an "O" type sealing ring rebound rate test device includes a bidirectional suction cup type double iron core electromagnet and a laser distance sensor 8 . The two-way suction cup type double iron core electromagnet includes a compression electromagnet 7, a rebound electromagnet 2, an "H" type moving iron core 3, 2 connecting plates and a "U" groove pressing plate 6. The structural size, compression force and rebound rate of the bidirectional suction cup type double iron core electromagnet are determined comprehensively according to the material, size and compression rate of the sealing ring, and the bidirectional suction cup type double iron core electromagnet adopts interlocking; The diameter and compression ratio of the sealing ring are determined; the aluminum thin strip 4 is made of aluminum thin with a length of 60 mm, a width of 5 mm, and 0.05 mm; the installation size, measurement range, accuracy and sampling frequency of the laser disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com