On-line monitoring system for flaw detection of steel wire rope for mines

A monitoring system and wire rope technology, applied in the field of non-destructive detection, can solve problems such as multi-function instruments, and achieve the effect of efficient work and improved signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

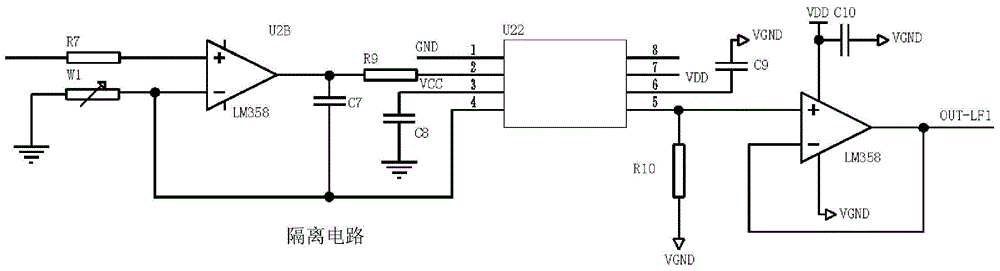

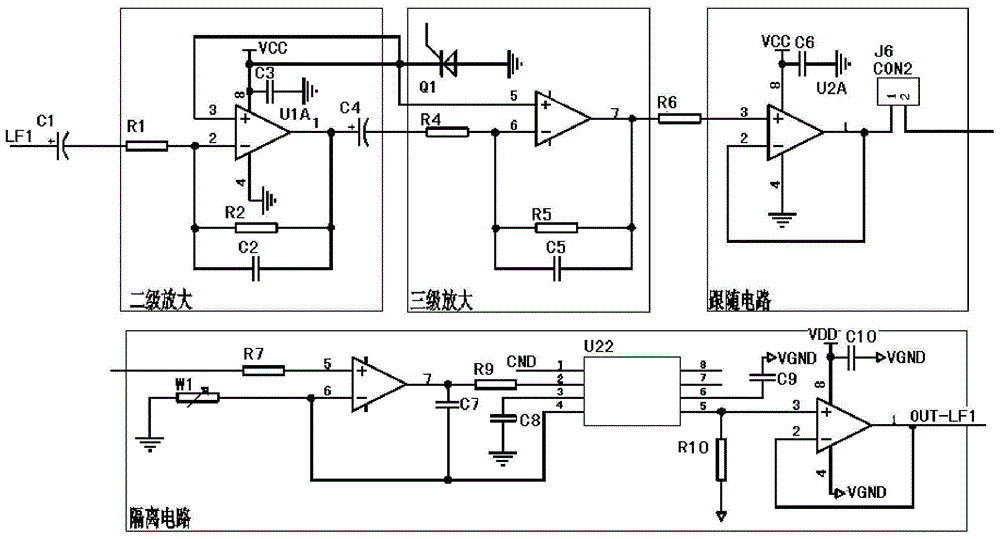

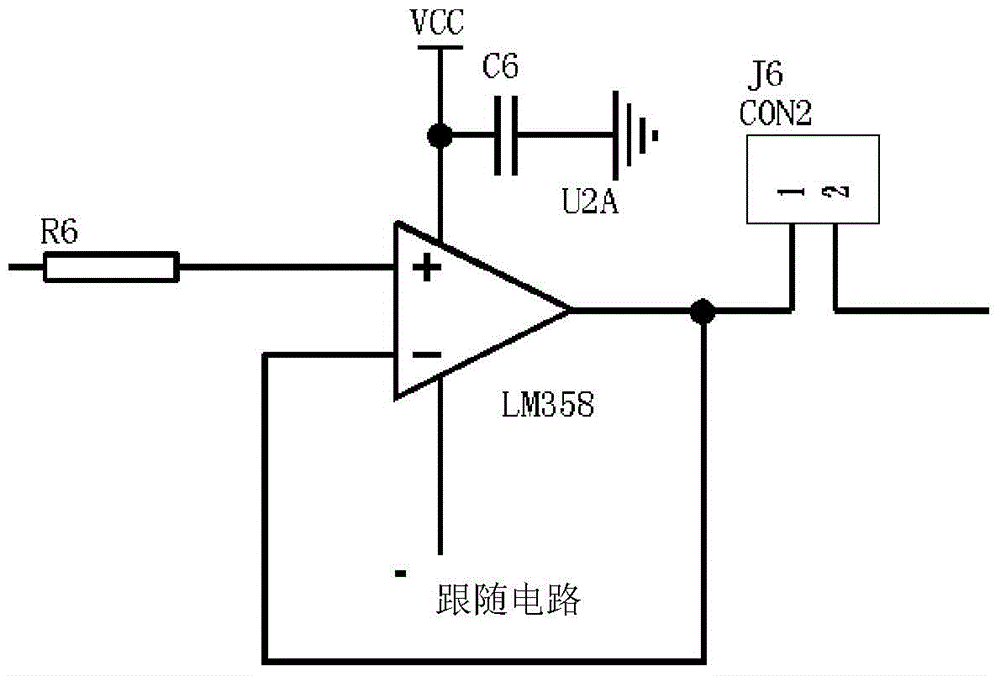

[0030] The following will further describe a monitoring system for a radiographic nondestructive testing equipment experiment of the present invention with reference to the accompanying drawings.

[0031] like figure 1 As shown, the system can be divided into seven parts: sensor 3 for mine wire rope flaw detection, wire rope flaw detection system detection frame 4, speed sensor 2, mine flameproof and intrinsically safe system information substation 8, mine flameproof type PLC control box 7, wire rope flaw detection system console 6, wire rope flaw detection intelligent analysis software.

[0032] Among them, the on-line monitoring system for mine wire rope flaw detection includes a pair of pulleys arranged on a bracket, a wire rope 9 is connected between the pair of pulleys, and a bracket driven by the detection frame 4 is arranged on the bracket below the pulleys. The sensor 3, the detection frame 4 is erected on the bracket and can move along its slideway, the detection fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com