Cement chemical shrinkage test device and method

A technology of chemical shrinkage and testing equipment, which is applied in the direction of material inspection products, etc., can solve the problems that the chemical shrinkage value cannot be measured, the shrinkage value cannot be measured, and the complexity of the operation is increased, so as to achieve complete test results, large test time range, The effect of short operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1, the steps are as follows:

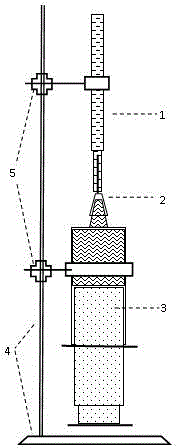

[0026] (1) Insert a No. 8 syringe needle into the "0" scale end of a 5ml glass graduated tube, and fix and seal the needle and the graduated tube with epoxy resin. After the epoxy resin is solidified, first inject a drop of engine oil into the glass scale tube through the needle, and then pour water into the glass scale tube to the full scale. Then fix the glass scale tube vertically on the bracket.

[0027] (2) Weigh 50g of cement, put it into a 50ml glass syringe with the outlet facing down, put the push handle of the glass syringe into the glass syringe, turn the syringe upside down, make the outlet upward, and then push the handle up into the syringe to a certain depth.

[0028] (3) Inhale 15ml of water from the outlet of the syringe, or use another 5ml syringe to inject 15ml of water into the test syringe in 3 times, block the outlet of the glass syringe and shake the glass syringe to fully mix the cement and water.

[00...

Embodiment 2

[0032] Embodiment 2, the steps are as follows:

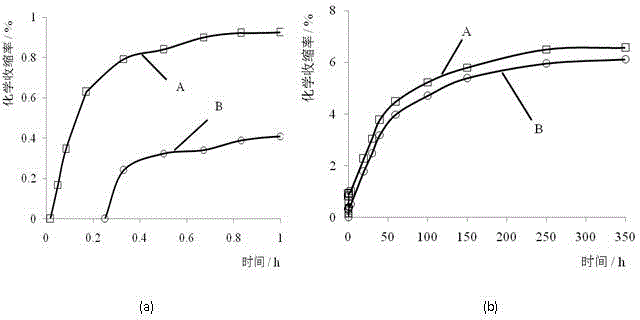

[0033] Test the chemical shrinkage value of 50g of cement under the condition of 0.3 water-cement ratio according to the operation of Example 1. The first reading time is the time when the syringe is finally fixed, which is about 1 minute after adding water to the cement. According to the change of the liquid level in the glass scale tube, read the volume shrinkage of different ages and convert it into chemical shrinkage. Taking time as the abscissa and the chemical shrinkage as the ordinate, draw the curve of the volumetric chemical shrinkage per unit weight of cement over time, which is denoted as curve A.

[0034] The chemical shrinkage of cement with the same mass and water-cement ratio is tested by traditional methods. Put 50g of cement into a glass bottle, add 15g of water and stir evenly, insert a rubber stopper with a glass measuring tube into the bottle mouth, and seal it with vaseline and paraffin. Use a dropper to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com