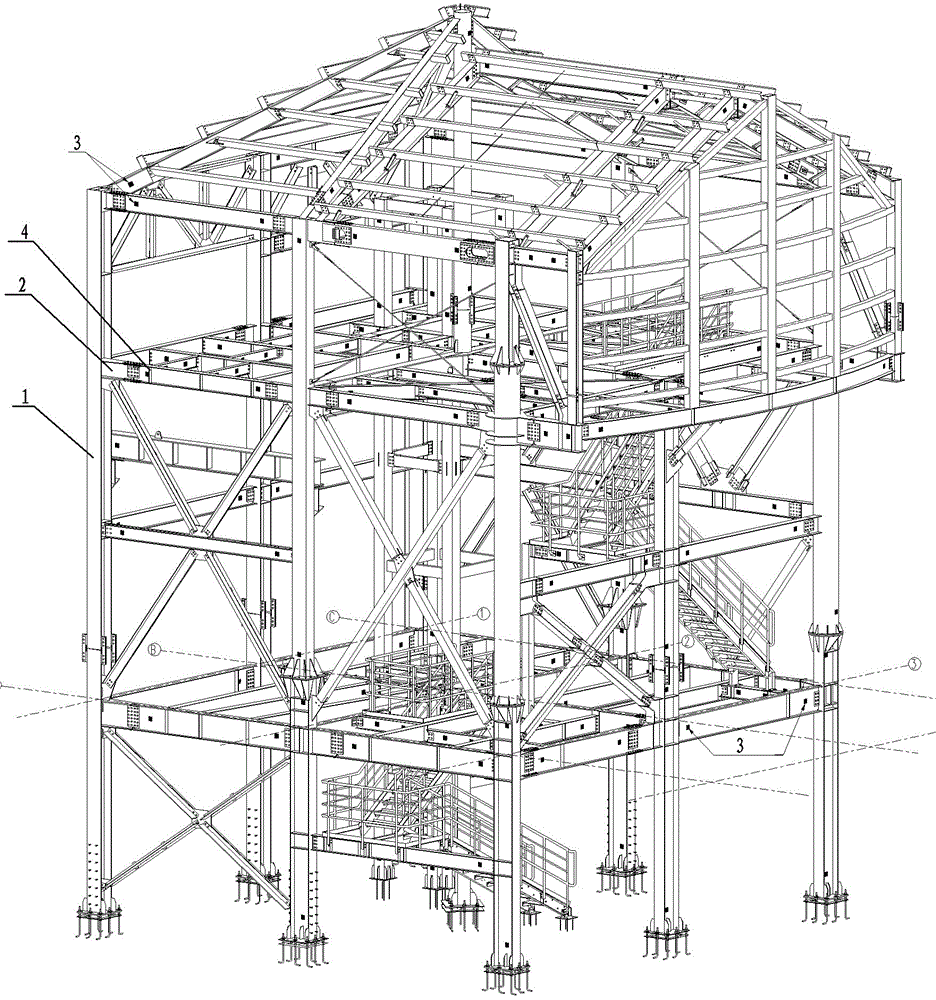

Steel structure detailed drawing labeling method based on BIM (building information modeling) system

A steel structure and detailed drawing technology, applied in electromagnetic radiation induction, special data processing applications, instruments, etc., to achieve the effect of improving dimensional accuracy and ensuring construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

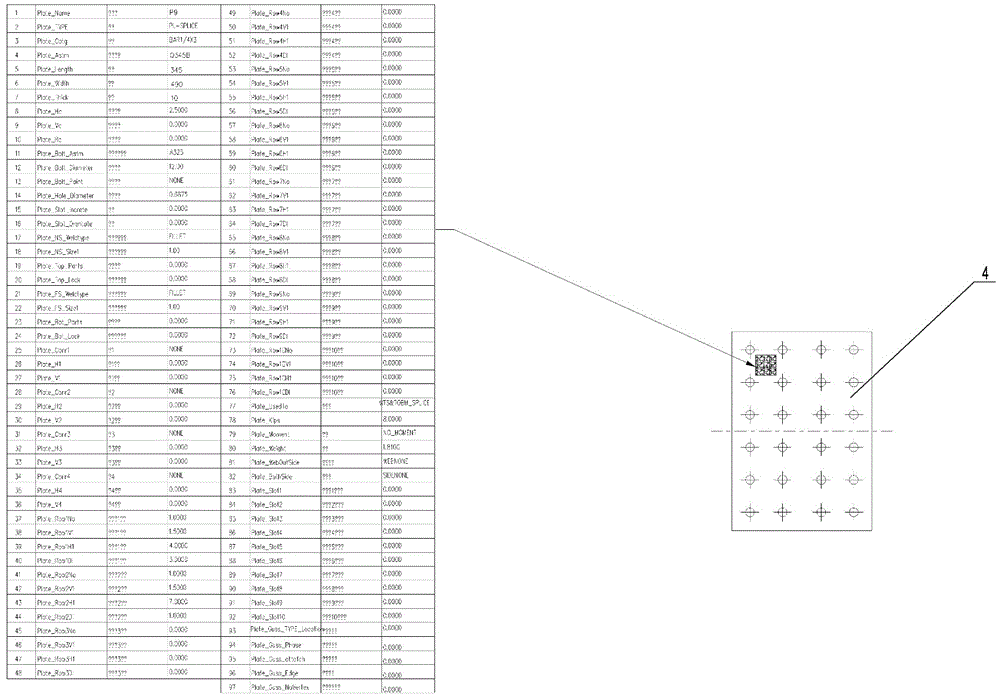

[0040] Embodiment 1: a method for marking steel structure detail drawings based on BIM system, comprising the following steps;

[0041] ①. Determine the size and specifications of the welding auxiliary positioning plate;

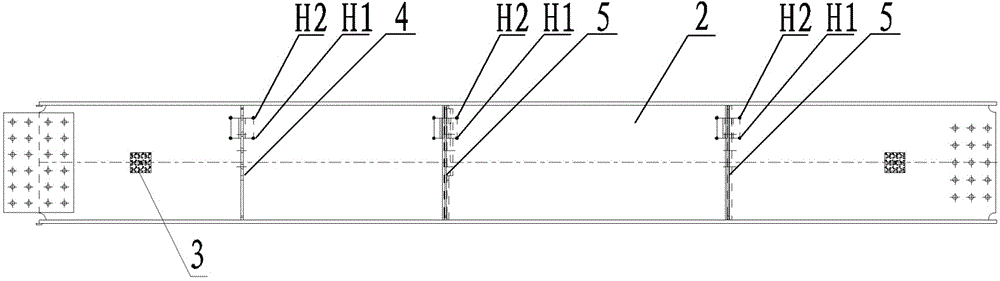

[0042] The types of welding auxiliary positioning plates include orthogonal positioning plates, oblique positioning plates,

[0043] The orthogonal positioning plate includes a lower plate and an upper plate, both of which are vertical, a magnet A is arranged in the lower plate for adsorption on the surface of the main body of the structure, and a magnet B is installed in the upper plate for adsorption between components. Positioning the connecting plate; the upper plate is provided with a positioning hole corresponding to the mounting hole of the positioning connecting plate, and the distance between the center of the positioning hole and the center line of the pre-installed inclined beam web is a fixed length n.

[0044] The oblique positioning plate incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com