Method and structure for improving inter-sheet uniformity of phosphorus concentration in doped polycrystalline or amorphous silicon

A technology of phosphorus concentration and amorphous silicon, which is applied in the field of improving the uniformity of doped polycrystalline or amorphous silicon phosphorus concentration between sheets, and improving the uniformity of doped polycrystalline or amorphous silicon phosphorus concentration between sheets, can solve the problem of Problems such as multiple particles and high cost, to achieve uniform distribution of phosphorus concentration, reduce production costs, and improve the uniformity of phosphorus concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

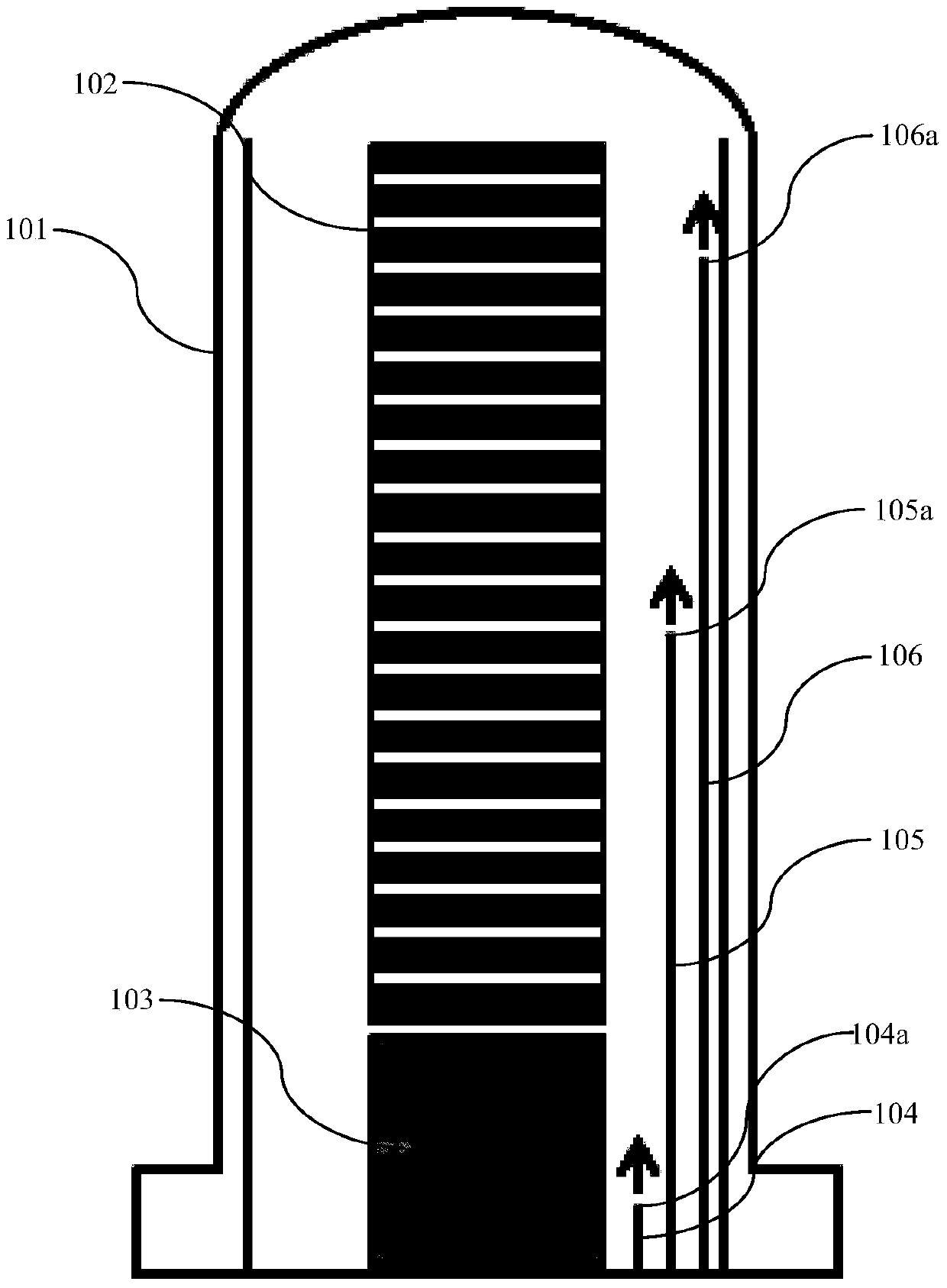

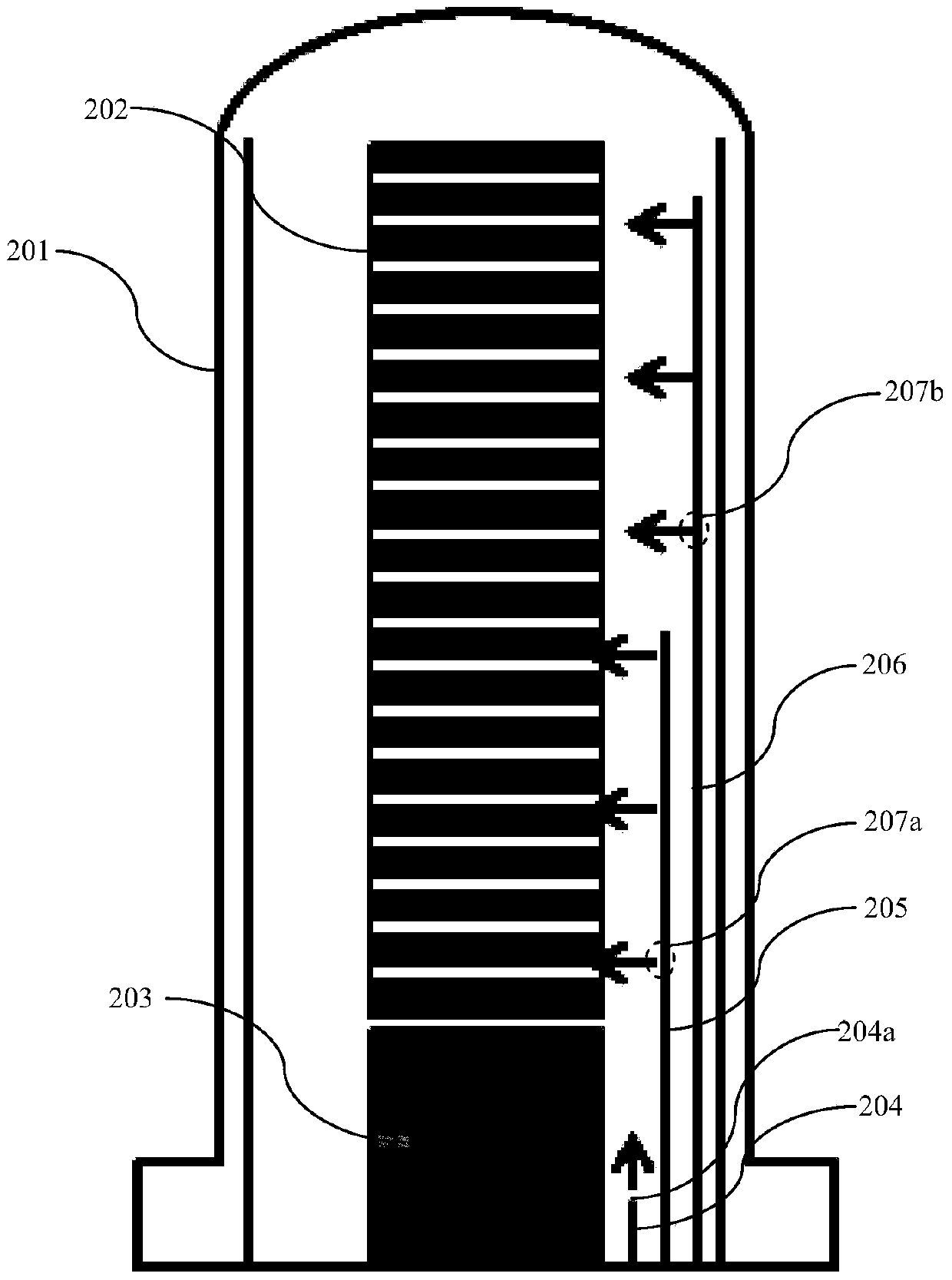

[0053] Such as image 3 Shown is a schematic structural view of the furnace tube 201 of the embodiment of the present invention; the embodiment of the present invention improves the uniformity of doped polycrystalline or amorphous silicon phosphorus concentration between sheets using the furnace tube 201 to grow polycrystalline silicon or amorphous silicon and simultaneously For phosphorus doping, a crystal boat 202 is arranged in the cavity of the furnace tube 201 , and the crystal boat 202 is placed on a heat preservation bucket 203 . The crystal boat 202 is used to place silicon wafers for growing polysilicon or amorphous silicon. Phosphine is used as a gas source for phosphorus doping, and the phosphine is passed into the cavity of the furnace tube 201 through a 3-way nozzle pipeline. In the body, the top of the first nozzle pipeline 204 is arranged on the bottom of the wafer boat 202, the top of the second nozzle pipeline 205 is arranged in the middle of the wafer boat 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com