Light emitting diode structure

A technology of light-emitting diodes and electrodes, applied to electrical components, circuits, semiconductor devices, etc., can solve the problems of low light reflectivity, limited light extraction efficiency, low reflectivity, etc., achieve high reflectivity, improve reflectivity, and increase reflection The effect of the angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

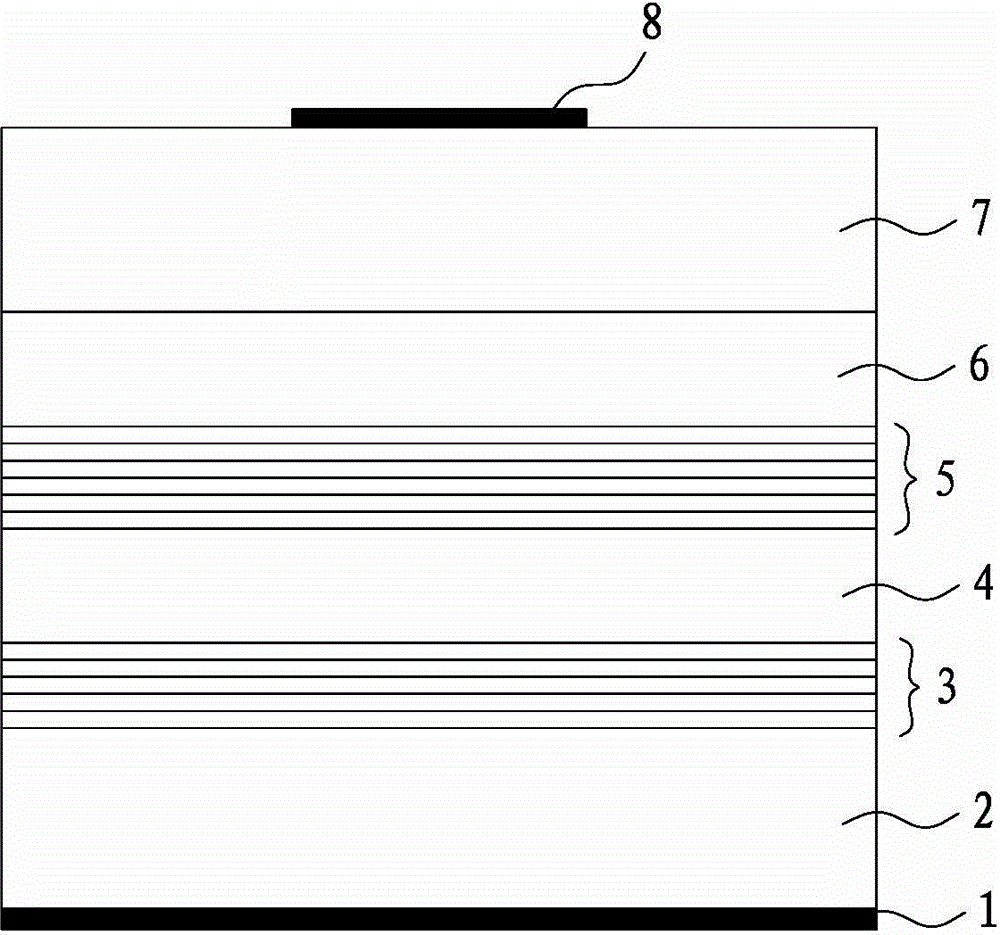

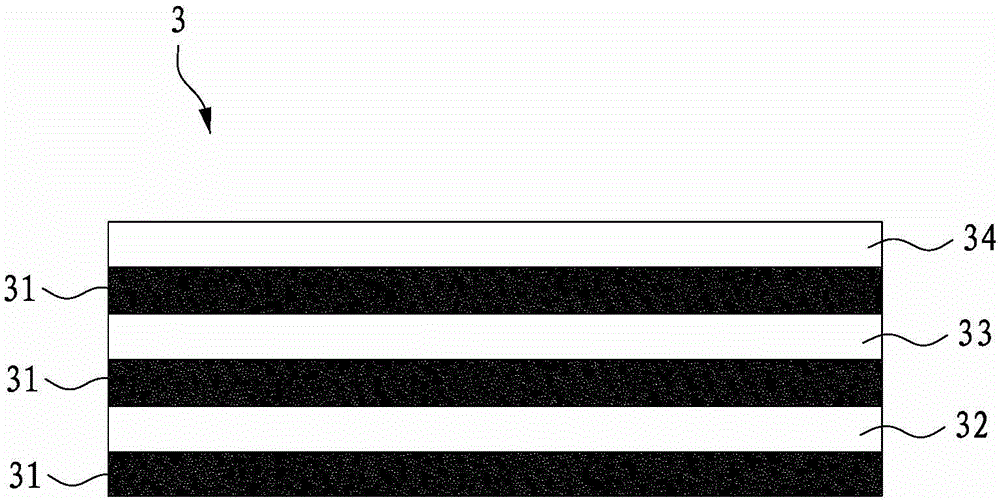

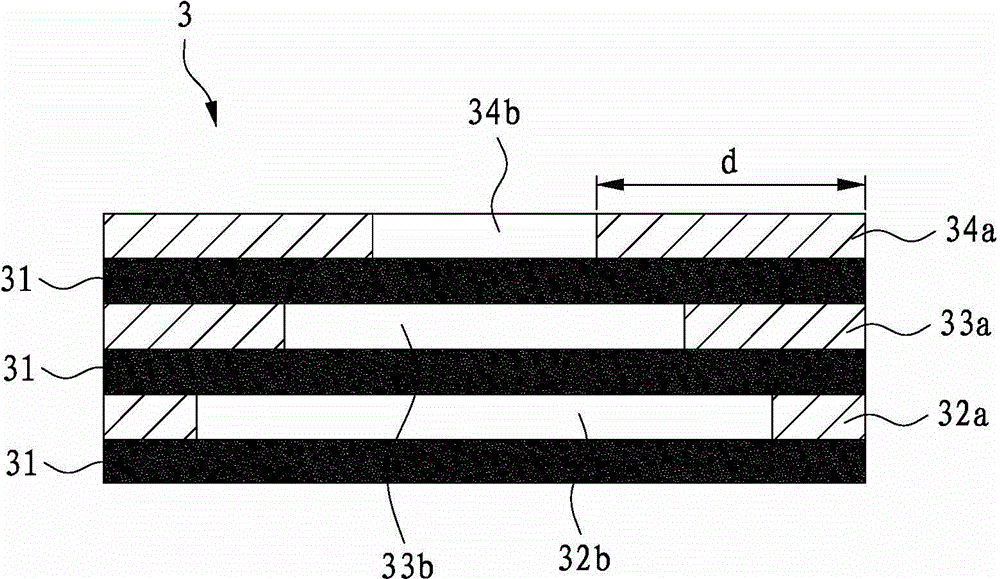

[0035] The invention discloses a light-emitting diode structure. A substrate is provided. There is a first electrode on the lower surface of the substrate, and a DBR reflective layer, a first-type confinement layer, an active layer, and a second-type confinement layer are sequentially distributed on the upper surface of the substrate. The confinement layer and the current spreading layer; the second electrode is formed on the current spreading layer; the low refractive index layer in the DBR reflective layer is partially oxidized, and the oxidation conditions are: the temperature is 300-600°C, and the oxidation is under the condition of water vapor; and The oxidation depth of each low refractive index layer changes gradually or periodically from bottom to top in the normal direction of the DBR reflective layer.

[0036] The DBR reflective lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com