Hybrid direct-current transmission converter and direct-current transmission device

A hybrid DC transmission and converter technology, applied in the fields of HVDC and UHV DC transmission, can solve the problems of increasing the loss and cost of the DC system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

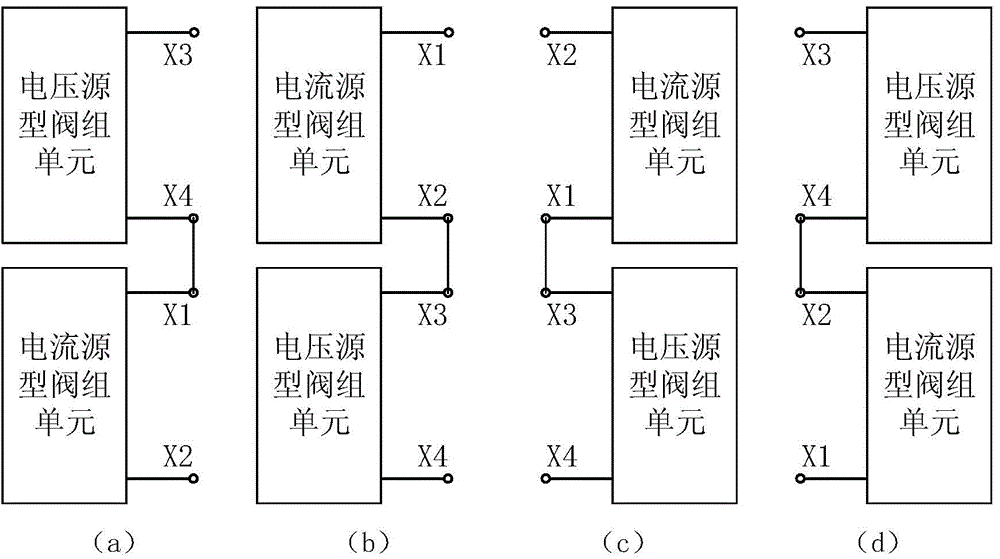

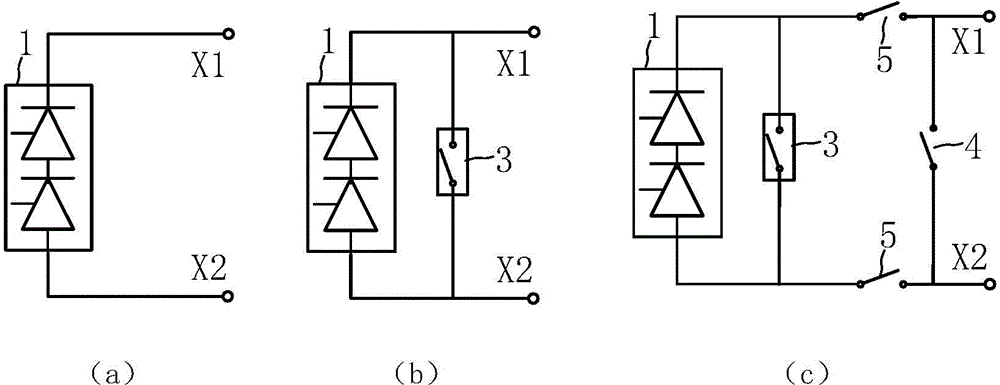

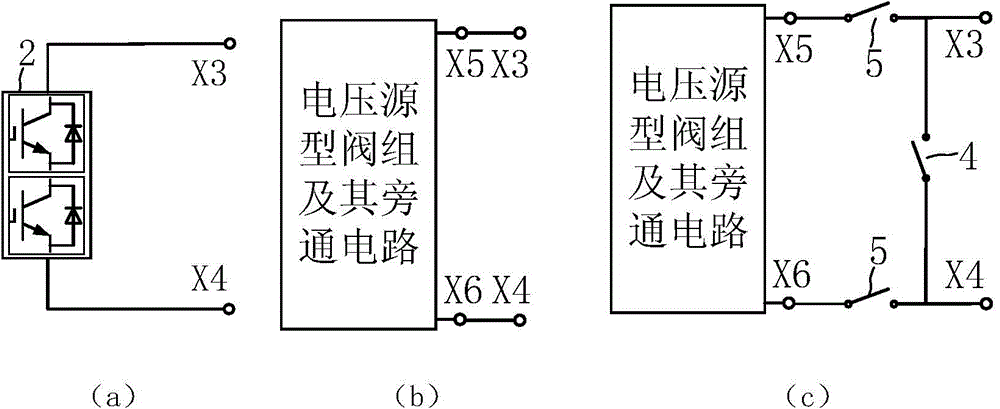

Embodiment 1

[0066] Figure 6 It shows that the HVDC power transmission device is all composed of Figure 5 An embodiment composed of the four topologies shown, which connect the rectifier station 20 and the inverter station 21 through the DC line 15 . The rectifier station 20 consists of topological structures (1) 16 and (2) 17 to form its negative converter and positive converter respectively, and the inverter station 21 consists of topological structures (3) 18 and (4) 19 to form its positive converter respectively. converter and negative pole converter. Valve group 1 is a current source valve group, which is connected to the 8 secondary windings of the thyristor-based current source high-voltage direct current transmission transformer, and valve group 2 is a voltage source type valve group, which is connected to the high voltage direct current transmission transformer based on a voltage source converter. The 9 secondary windings of the transformer are connected. It should be pointed...

Embodiment 2

[0071] Figure 7 It shows that the HVDC power transmission device consists of a traditional current source valve group converter and Figure 5An example of two topologies is shown. The rectifier station 20 of the HVDC power transmission device is composed of a topology 24 in which current source valve units are connected in series, and the inverter station 21 is composed of topological structures (3) 18 and (4) 19 to form its positive converter and negative converter respectively. Valve group 1 is a current source valve group, which is connected to the 8 secondary windings of the thyristor-based current source high-voltage direct current transmission transformer, and valve group 2 is a voltage source type valve group, which is connected to the high voltage direct current transmission transformer based on a voltage source converter. The 9 secondary windings of the transformer are connected. The rectifier station 20 is configured with an AC filter 23 to filter harmonics and pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com