Heater

A heating device and heat-insulating tank technology, applied in electric heating devices, water heaters, fluid heaters, etc., can solve the problems of shortening the service life of heating elements, shortening the service life of heating devices, and being prone to rust and corrosion. To achieve the effect of improving heat conduction efficiency, long service life and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The heating device of the present invention is suitable for heating various liquids, or heating various liquids to generate steam.

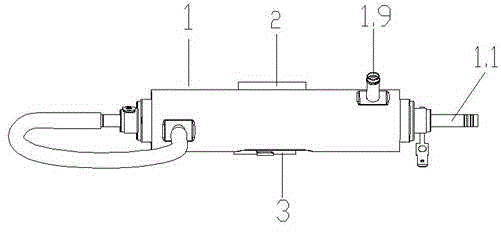

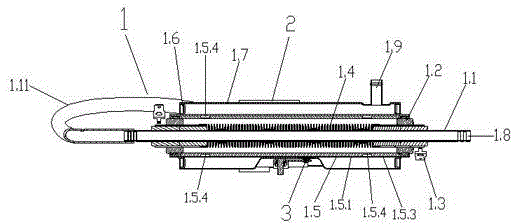

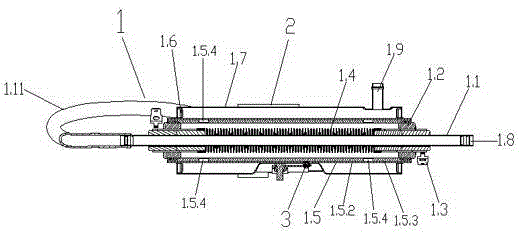

[0028] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 The preferred embodiment (1) of the heating device of the present invention will be described in detail below.

[0029] A heating device in this embodiment includes a housing 1.5 and a heating element 1.4, and the heating element 1.4 is located in the housing 1.5, and is characterized in that: the housing 1.5 includes two layers, which are respectively the inner layer The shell 1.5.1 and the outer shell 1.5.3, the inner shell 1.5.1 and the outer shell 1.5.3 are in close contact, and the inner shell 1.5.1 is made of aluminum tube, the outer shell 1.5.3 is a stainless steel tube.

[0030] Because the aluminum tube 1.5.1 not only has good thermal conductivity, but also is easy to deform, so in the production process of the heating device of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com