Coating composition containing polyamide-imide resin

A technology of imide resin and composition, applied in lubricating compositions, coatings, additives, etc., can solve problems such as weakening of lubricating durability, and achieve the effect of excellent lubricating durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

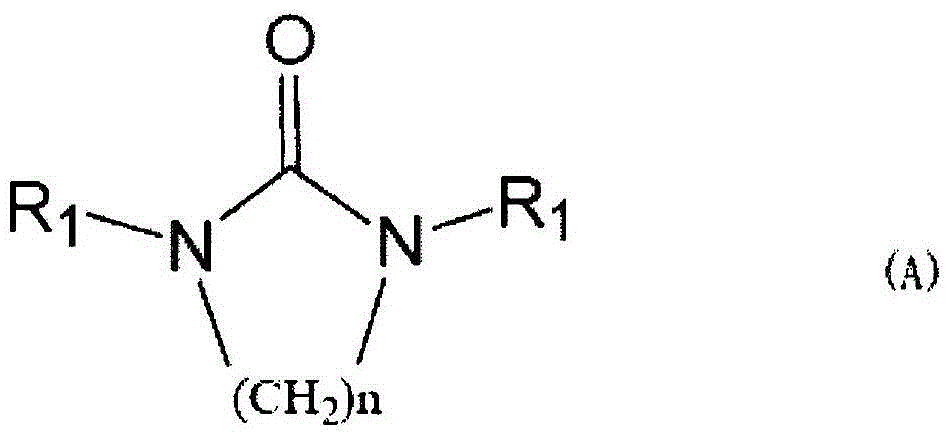

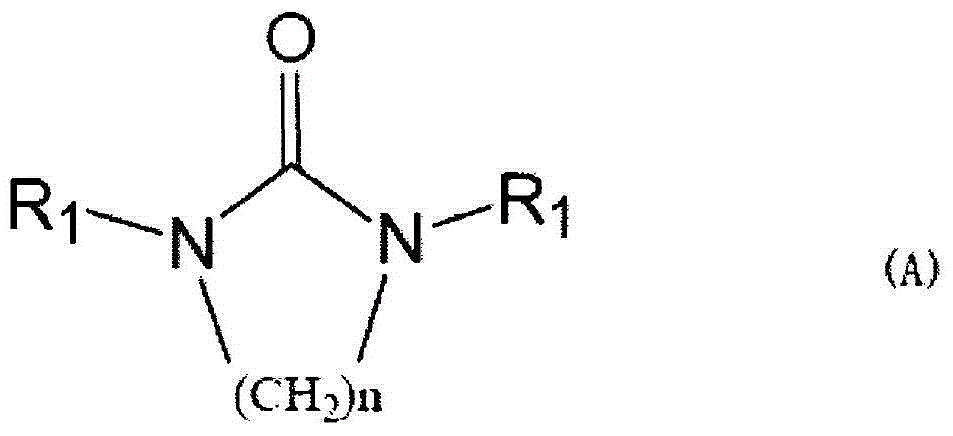

Image

Examples

example

[0066] Hereinafter, the present invention will be described in detail based on practical examples, but the present invention is not limited to these practical examples.

[0067] [Practical example 1]

[0068] Powdered graphite was added to a polyamide-imide resin solution (manufactured by Hitachi Chemical Co., Ltd.) prepared in 1,3-dimethyl-2-imidazolidinone (DMI). , solid content: about 30% by mass), the solution contains polyamide-imide resin dissolved in DMI, so that the content of powdered graphite is 50 parts by mass per 100 parts by mass polyamide-imide resin, and then Mix at room temperature. This mixture was diluted with DMI so that the solid content concentration was 15% by mass to form a coating composition to be used in evaluation tests.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com