Garbage sorting production line

An assembly line and garbage technology, applied in sorting and other directions, can solve problems such as high energy consumption and complex machinery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

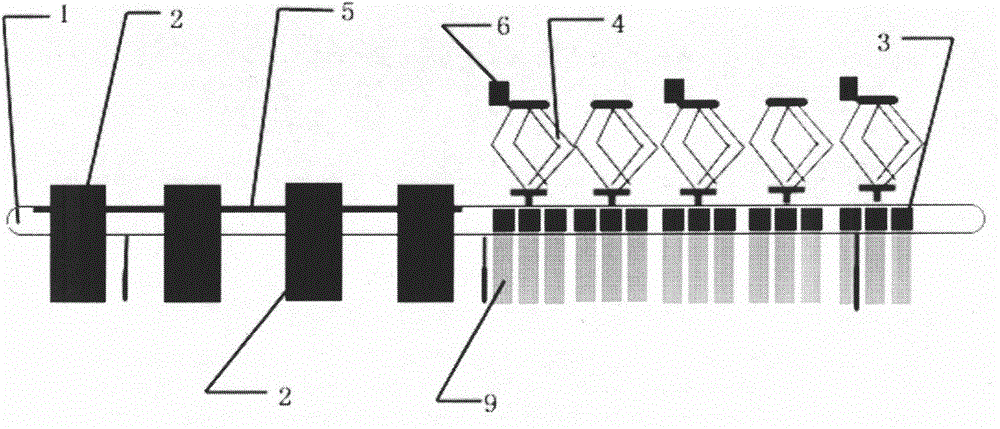

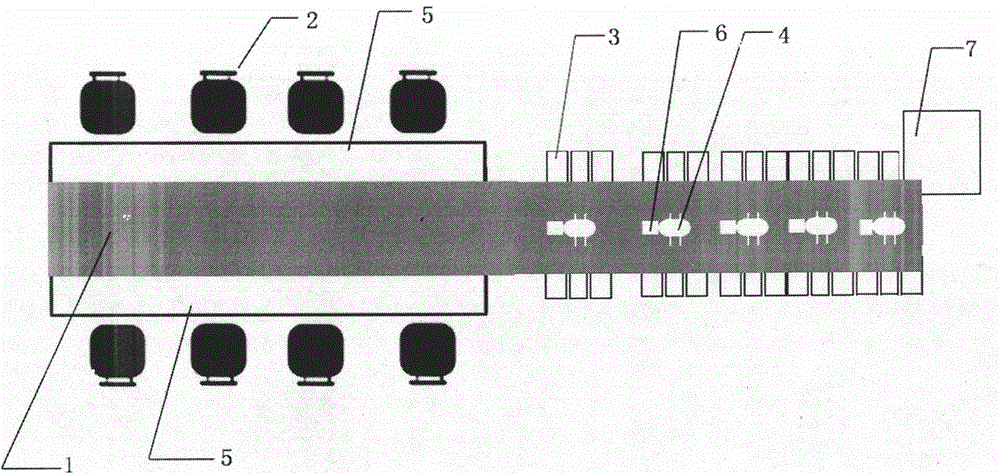

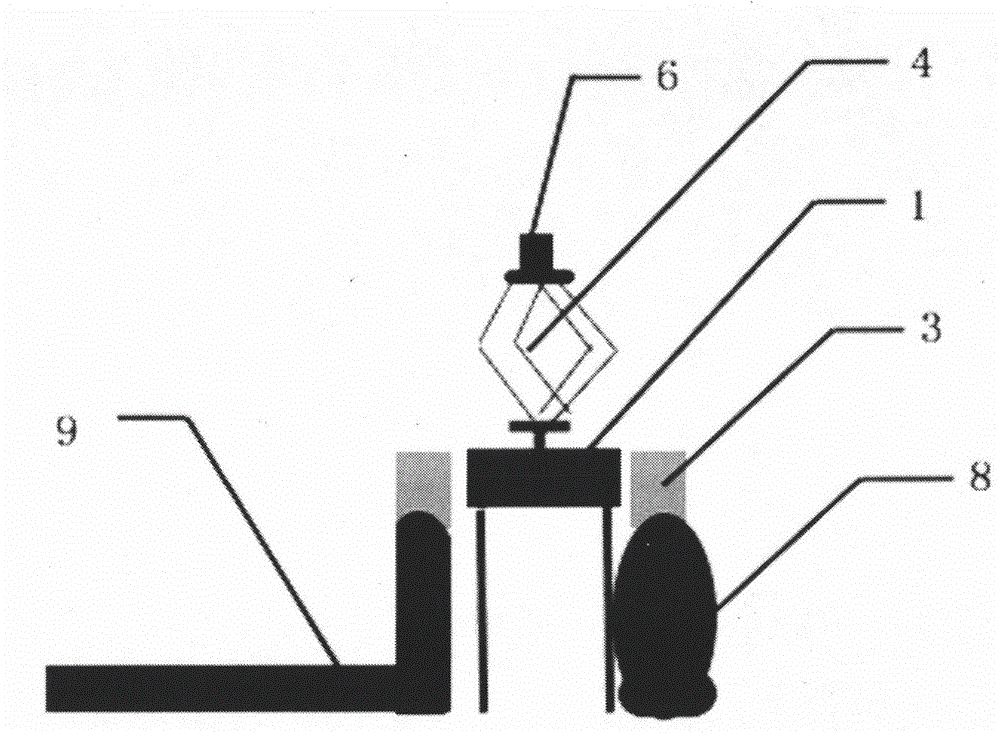

[0025] Embodiment 1 The electric belt conveyor 1 is divided into two parts, the front section and the rear section, and five parallel manipulators 4 are arranged in the back section near the discharge port. The device 6 boots. Three feeding ports 3 are arranged on both sides of each parallel manipulator 4 , and each feeding port 3 is connected to a pocket 8 . A workbench 5 with a width of 0.2 meters is set on both sides of the front section of the conveyor belt, and a seat 2 is set on the outside of the workbench 5. In addition to the spectral identification device 6 at the end of the assembly line, the previous spectral identification device 6 can provide the two parallel manipulators 4 with information on material composition, position and movement speed, and guide the two parallel manipulators 4 .

[0026] The parallel manipulator 4 guided by the spectral identification device 6 near the end of the assembly line and the governor of the electric belt conveyor 1 use paired B...

Embodiment 2

[0027] Embodiment 2 Five parallel manipulators 4 are set on the electric belt conveyor 1, and the parallel manipulators 4 are guided by the spectrum identification device 6. Three feeding ports 3 are arranged on both sides of each parallel manipulator 4, and each feeding port 3 is connected to a material Delivery pipeline 9. The parallel manipulator 4 guided by the spectral identification device 6 near the end of the assembly line and the governor of the electric belt conveyor 1 transmit data instructions through the data line, and the parallel manipulator 4 guided by the spectral identification device 6 sends the electric belt conveyor according to the quantity of non-selected materials. The speed governor of machine 1 sends out the instruction of speed-up or speed-down.

[0028] There is a spectral identification device 63 on both sides of the parallel manipulator 4 at the end, and the parallel manipulator 4 detects and puts the non-main selection material into it, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com