Claw disc clamp for gear finish machining

A technology for finishing and hobbing jig, applied in the direction of manufacturing tools, components with teeth, metal processing equipment, etc., can solve the problem that the positioning accuracy cannot meet the processing requirements, the strength of the gear jig is not enough, and it cannot adapt to rapid production, etc. The effect of avoiding clamping failure, simple structure and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

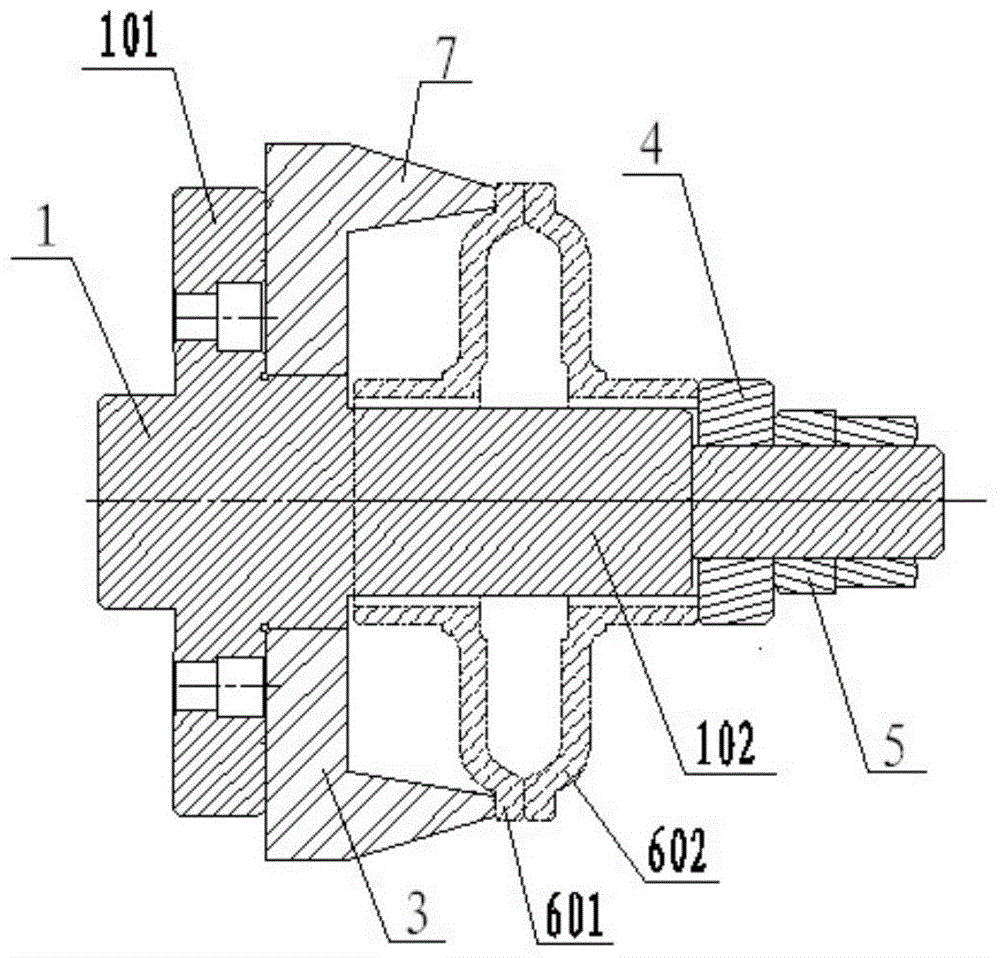

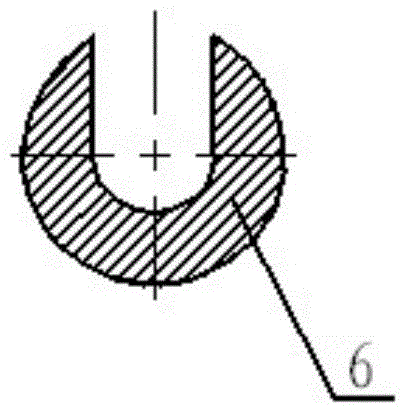

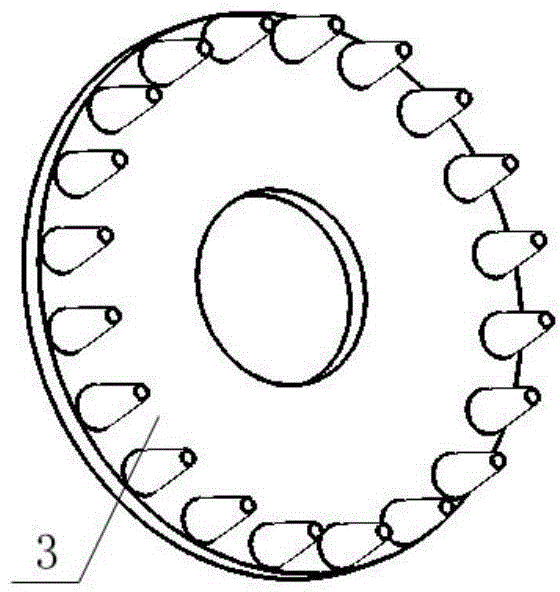

[0022] Such as Figure 1-Figure 3 As shown, its structural relationship is that the present invention includes a clamp head 1, the left end of the clamp head 1 is a disc-shaped base 101 with cylindrical bosses on both sides, the right end is a cylindrical spindle 102 with threads, and the right cylindrical boss A disc-shaped backing plate 3 with a sharp edge and a shaft hole inside is installed on the top; elastic jacket one 601 and elastic jacket two 602 are installed on the main shaft 102, and the threaded part and the nut 5 cushioned with cushion 4 connect.

[0023] Preferably, several positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com