Microwave sintering synthesis method of oxide thermoelectric material Ca3-xKxCo4O9

A technology of ca3-xkxco4o9 and thermoelectric materials, applied in chemical instruments and methods, cobalt compounds, inorganic chemistry, etc., can solve the problems of high energy consumption, long cycle, unfavorable mass production of thermoelectric materials, etc., and achieve simple operation, The effect of low cost and outstanding thermoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

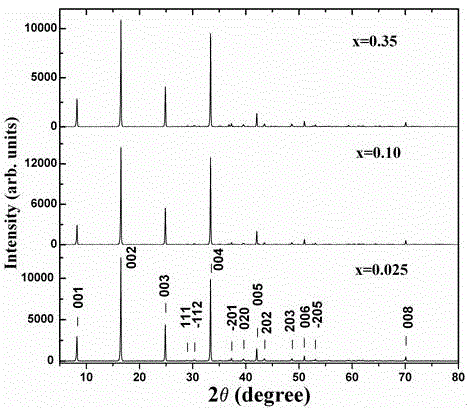

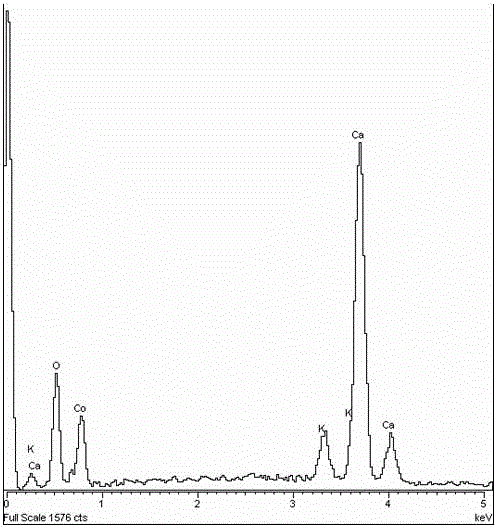

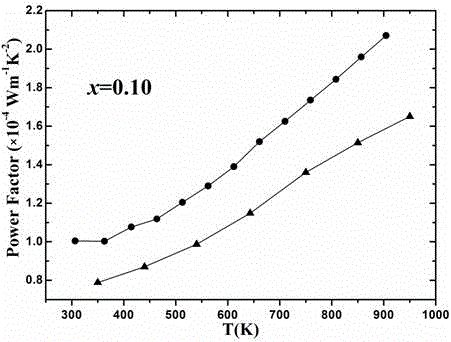

[0018] Oxide thermoelectric material Ca 3-x K x co 4 o 9 The microwave sintering synthesis method, wherein 0﹤x≤0.35, is completed according to the following steps:

[0019] (1), first put the analytical reagent CaCO 3 、K 2 CO 3 、Co 2 o 3 Press Ca 3-x K x co 4 o 9 Weigh the stoichiometric molar ratio of Ca:K:Co=3-x:x:4. After grinding, put the ground powder in an alumina crucible, then place it in a box furnace, and heat it to a constant temperature of 850°C After pre-burning for 24 hours, cool down to room temperature with the furnace and take it out;

[0020] (2) The pre-fired powder is ground for the second time and then pressed into a disc. The double crucible is used to hold the tablet, and then the double crucible is placed in a household flat-panel microwave oven, heated at 400W for 15 minutes and then cooled with the furnace. To room temperature, take out the compressed tablet to obtain the target product. Wherein, the double-crucible holding tablet is ope...

Embodiment 2

[0026] The difference from Example 1: In step (1), pre-fire at a constant temperature of 820° C. for 30 hours.

Embodiment 3

[0028] The difference from Example 1; in step (1), pre-fire at a constant temperature of 880°C for 20h; in step (2), heat at 640W for 10min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com