An anaerobic reactor for treating sewage containing sludge

An anaerobic reactor and sludge technology, which is applied in the field of anaerobic reactors, can solve the problems of difficult uniform water distribution and three-phase separators that are difficult to achieve operational stability, and achieve uniform water distribution, good operational stability, and extended Effect of Anaerobic Reaction Time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

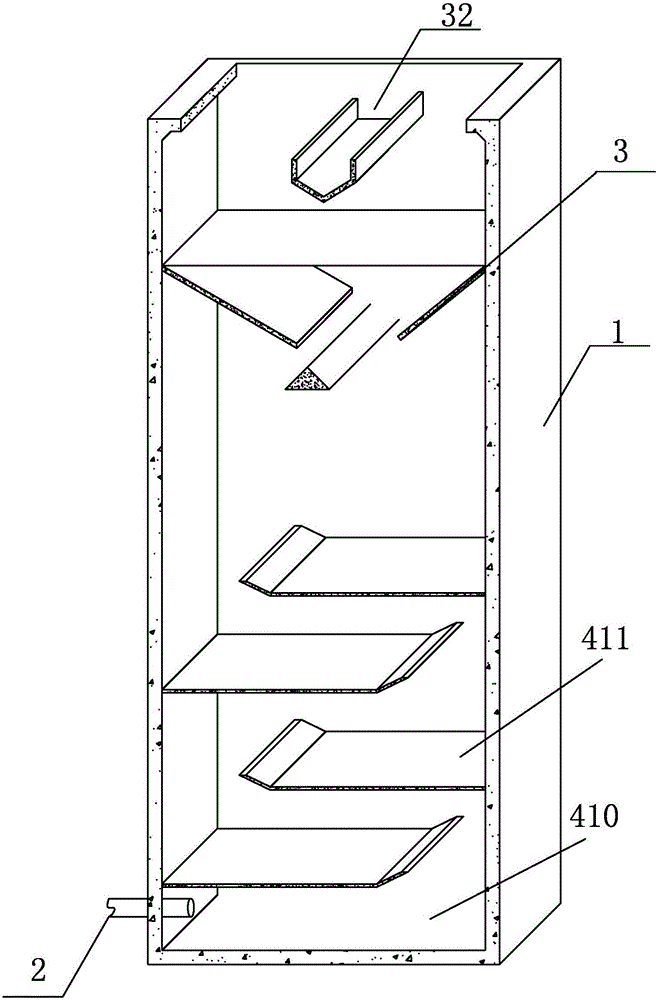

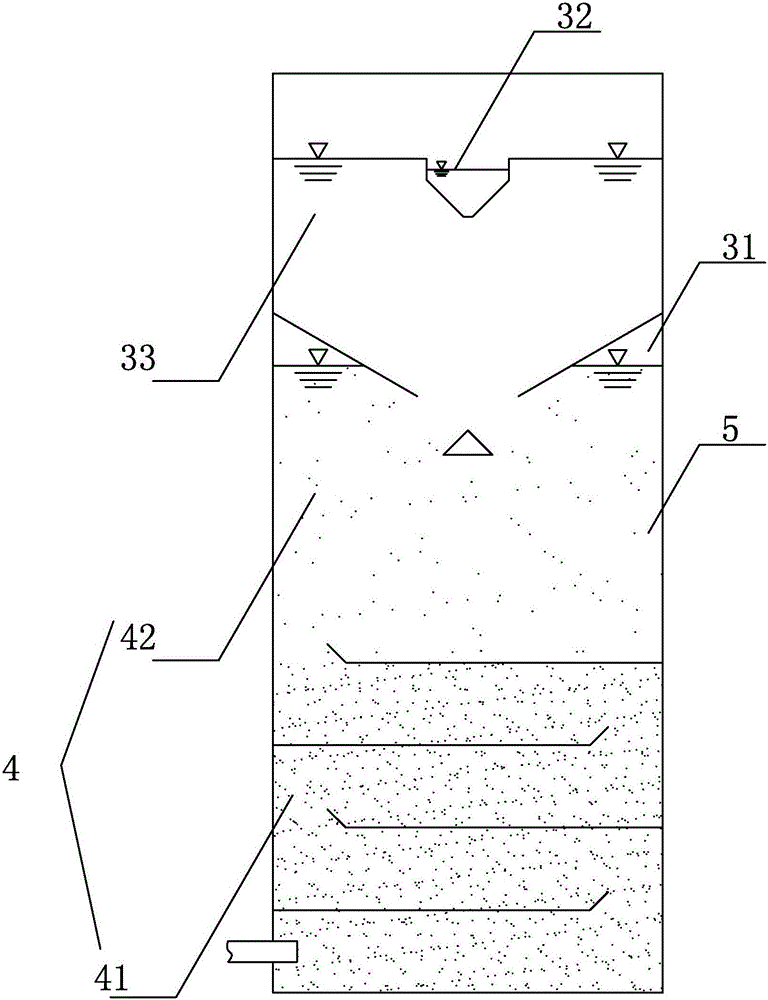

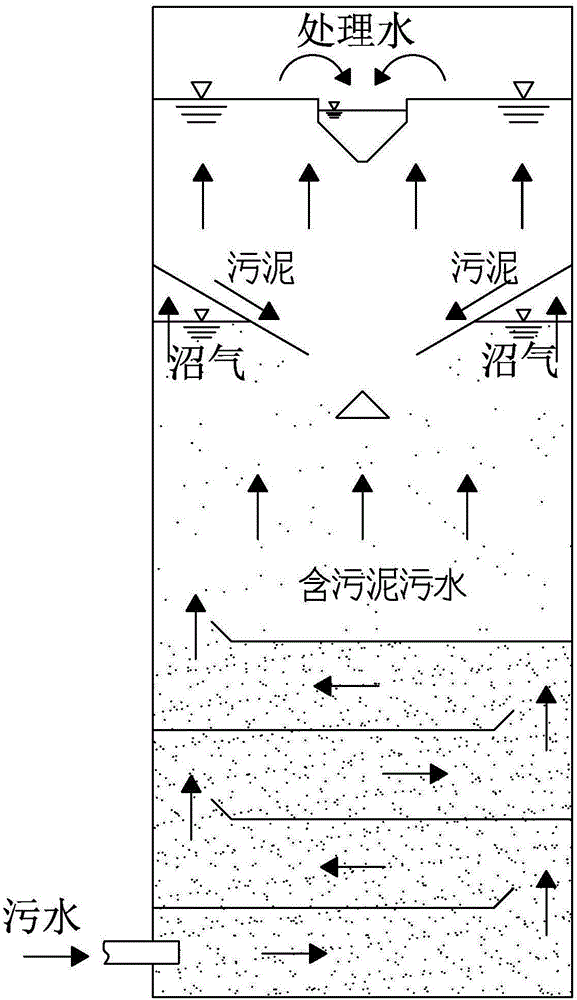

[0022] combine Figure 1 to Figure 3 For reference, the anaerobic reactor for treating sludge-containing sewage according to the embodiment of the present invention includes: a container body 1, an inlet water distribution system 2 arranged at the bottom of the container body 1, and a three-phase separator arranged at the top of the container 3.

[0023] Wherein, the area of the container body 1 located between the water inlet distribution system 2 and the three-phase separator 3 is also provided with a sludge bed area 41, and the sludge bed area 41 is arranged circuitously inside the container body 1 along the direction from bottom to top. A water distribution corridor 410 is formed, and the sludge bed area 41 is filled with granular sludge containing anaerobic microorganisms with good settleability.

[0024] Under the state of use, the sludge-co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com