High-strength stretch-proof flame-retardant cable material

A flame-retardant cable material and stretch-resistant technology, applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve problems such as cable rupture, affecting safe production, and falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

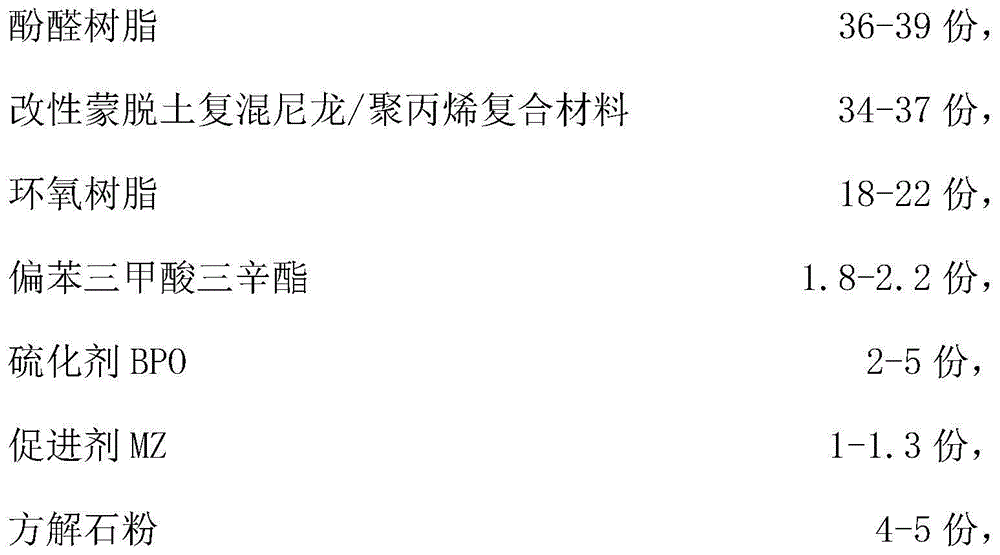

[0017] A high-strength stretch-resistant flame-retardant cable material proposed by the present invention, its raw materials include by weight:

[0018]

[0019] In the preparation process of the modified montmorillonite compound nylon / polypropylene composite material, 5 parts of montmorillonite, 3 parts of salt, 16 parts of water and 25 parts of acid solution are added to the first reaction vessel in parts by weight, and the first reaction The temperature of the container and its contents was raised to 65°C, kept warm for 1.5 hours, then filtered, washed, and dried to obtain material A; material A and 100 parts of deionized water were added to the second reaction container for ultrasonic dispersion to obtain solution B, and the ultrasonic dispersion time 2h, the frequency of ultrasonic dispersion is 35KHz, and the power of ultrasonic dispersion is 1600W, then add 6 parts of stearic acid to the second reaction vessel, raise the temperature of the second reaction vessel and i...

Embodiment 2

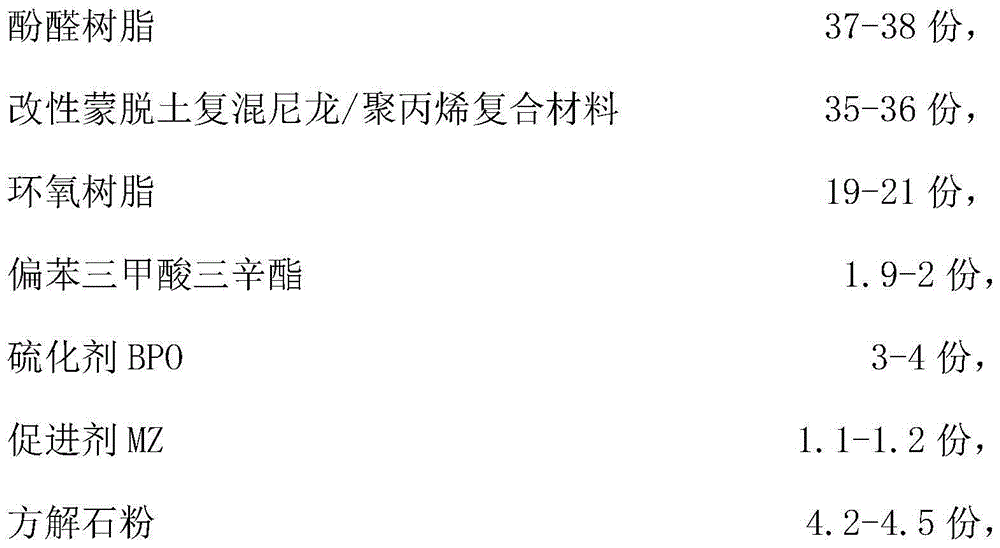

[0021] A high-strength stretch-resistant flame-retardant cable material proposed by the present invention, its raw materials include by weight:

[0022]

[0023] During the preparation process of the modified montmorillonite composite nylon / polypropylene composite material, 8 parts of montmorillonite, 2.5 parts of salt, 17 parts of water and 20 parts of acid solution are added to the first reaction vessel by weight, and the first reaction The temperature of the container and its contents was raised to 70°C, kept warm for 1 hour, then filtered, washed, and dried to obtain material A; material A and 120 parts of deionized water were added to the second reaction container for ultrasonic dispersion to obtain solution B, and the ultrasonic dispersion time was 1.5h, the frequency of ultrasonic dispersion is 38KHz, the power of ultrasonic dispersion is 1500W, then add 9 parts of stearic acid to the second reaction vessel, raise the temperature of the second reaction vessel and its ...

Embodiment 3

[0025] A high-strength stretch-resistant flame-retardant cable material proposed by the present invention, its raw materials include by weight:

[0026]

[0027] In the preparation process of the modified montmorillonite compound nylon / polypropylene composite material, 6 parts of montmorillonite, 4 parts of salt, 15 parts of water and 23 parts of acid solution are added to the first reaction vessel in parts by weight, and the first reaction The temperature of the container and its contents was raised to 66°C, kept warm for 1.4 hours, then filtered, washed, and dried to obtain material A; material A and 105 parts of deionized water were added to the second reaction container for ultrasonic dispersion to obtain solution B, and the ultrasonic dispersion time 1.8h, the frequency of ultrasonic dispersion is 36KHz, the power of ultrasonic dispersion is 1580W, then add 7 parts of stearic acid to the second reaction vessel, raise the temperature of the second reaction vessel and its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com