A kind of yellow fluorescent powder for white light LED suitable for blue light excitation and preparation method thereof

A technology excited by yellow phosphor powder and blue light, applied in chemical instruments and methods, luminescent materials, etc., can solve problems such as high color temperature, low color rendering index, and poor thermal characteristics, and achieve the effect of reducing color temperature and improving color rendering index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Material selection according to chemical formula M 1-x N 2-y+x Al 1-x Si x o 5 :Eu y , where M is La, N is Sr, x=0.10, y=0.02, and high-purity SrCO is weighed according to its mole percentage 3 , Al 2 o 3 , SiO 2 , La 2 o 3 and Eu 2 o 3 , put it into a crucible after fully grinding and reduce the atmosphere H at 1100°C 2 / N 2 (10% / 90%) and sintered for 4 hours, took it out after cooling, and transferred it to a crucible after being ground. 2 / N 2 (10% / 90%) and sintering for 6 hours to obtain the final product.

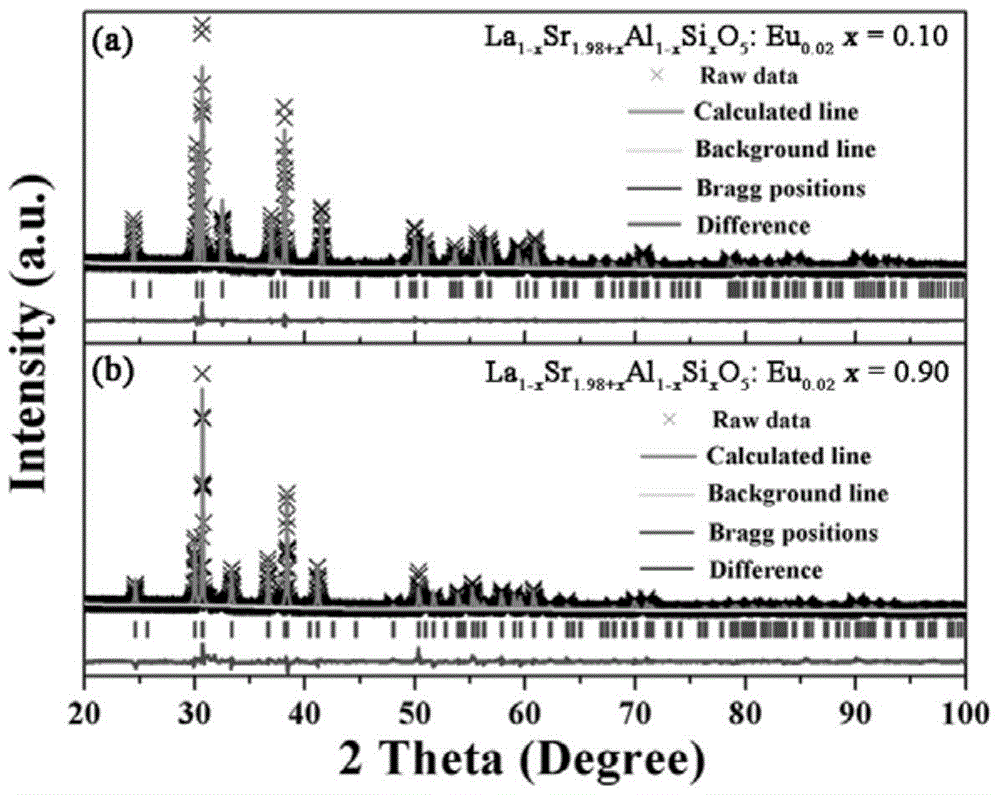

[0018] figure 1 a is prepared by the present embodiment to obtain europium ion-doped La 1-x Sr 2-y+x Al 1-x Si x o 5 :Eu y (x=0.10, y=0.02) XRD spectrum of the luminescent material; indicating that we have successfully prepared the material.

Embodiment 2

[0020] Material selection according to chemical formula M 1-x N 2-y+x Al 1-x Si x o 5 :Eu y , where M is La, N is Sr, x=0.50, y=0.02, and high-purity SrCO is weighed according to its molar percentage 3 , Al 2 o 3 , SiO 2 , La 2 o 3 and Eu 2 o 3 , put it into a crucible after fully grinding and reduce the atmosphere H at 1200°C 2 / N 2 (10% / 90%) and sintered for 4 hours, took it out after cooling, and transferred it to a crucible after being ground. 2 / N 2 (10% / 90%) and sintering for 6 hours to obtain the final product.

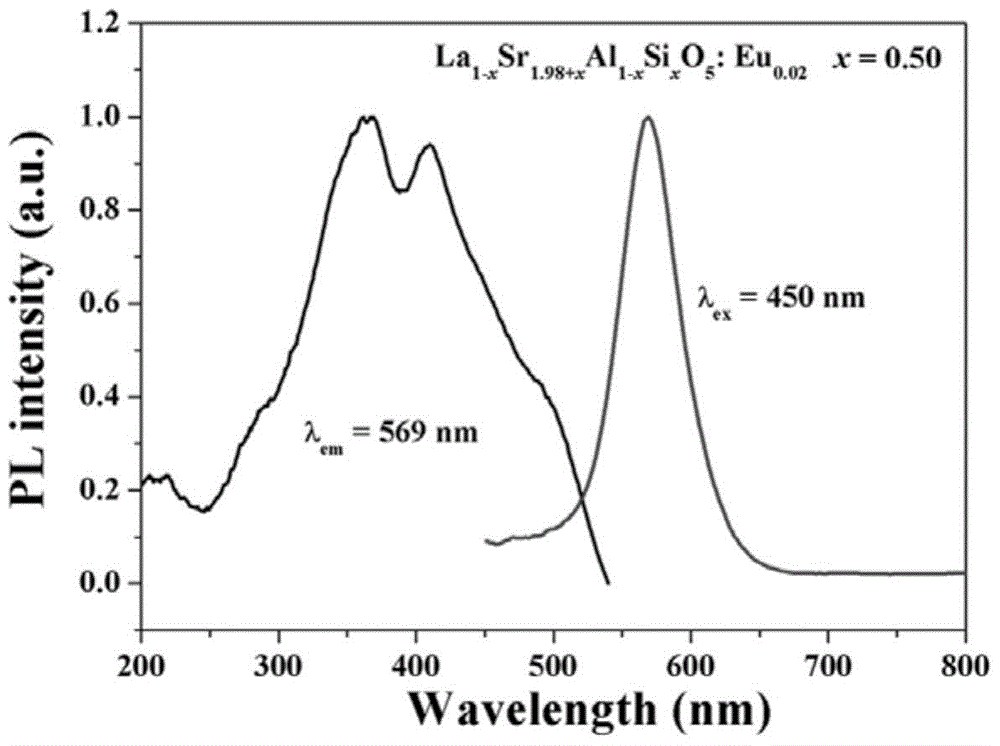

[0021] figure 2 For the La prepared by this example 1-x Sr 2-y+x Al 1-x Si x o 5 :Eu y (x=0.50, y=0.02) Excitation and emission spectra of the luminescent material.

Embodiment 3

[0023] Material selection according to chemical formula M 1-x N 2-y+x Al 1-x Si x o 5 :Eu y , where M is La, N is Sr, x=0.90, y=0.02, and high-purity SrCO is weighed according to its mole percentage 3 , Al 2 o 3 , SiO 2 , La 2 o 3 and Eu 2 o 3 , put it into a crucible after fully grinding and reduce the atmosphere H at 1100°C 2 / N 2 (10% / 90%) and sintered for 4 hours, took it out after cooling, and transferred it to a crucible after grinding, and reduced the atmosphere H at 1600 ° C. 2 / N 2 (10% / 90%) and sintering for 6 hours to obtain the final product.

[0024] figure 1 b is prepared by the present embodiment to obtain europium ion-doped La1-x Sr 2-y+x Al 1-x Si x o 5 :Eu y (x=0.90, y=0.02) XRD spectrum of the luminescent material; it shows that we have successfully prepared the material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com